Friction damper for frame structure joint and building frame structure

A friction damper and frame structure technology, which is applied to building components, buildings, building types, etc., can solve the problems of not compactness, occupied space, and complex structure of friction dampers, so as to improve energy dissipation and increase friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

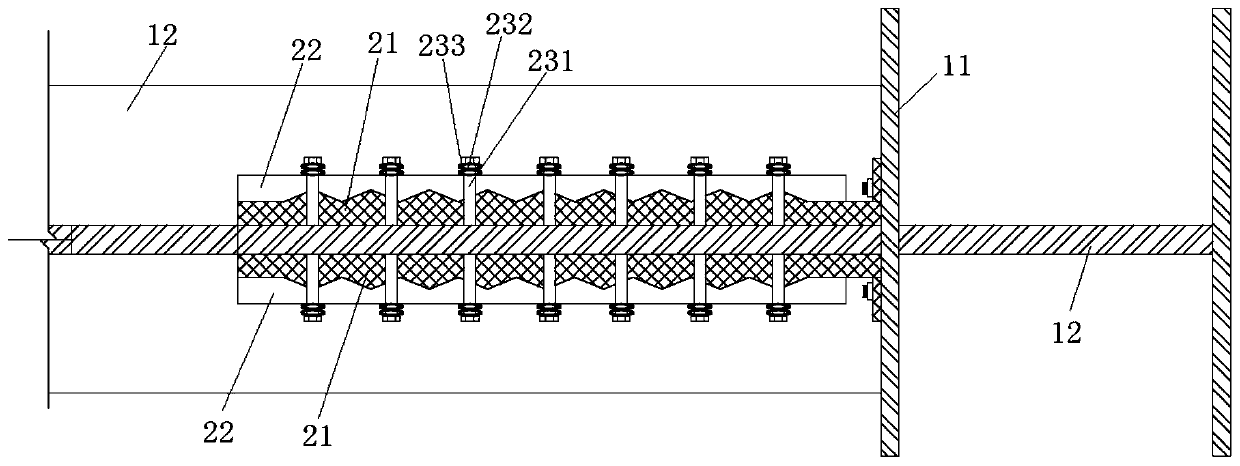

[0055] This embodiment provides a friction damper for frame structure joints, such as Figure 1 to Figure 11 As shown, it includes at least one first energy consumption board 21 , at least one second energy consumption board 22 , and at least one prestressed component 23 .

[0056] For example, if image 3 As shown, there are two first energy consumption boards 21 and two second energy consumption boards 22 respectively, and there are several prestressed components 23 . For the first energy consumption board 21, as Figure 4a As shown, the first energy consumption board 21 is provided with a first elongated hole 211 extending along its length direction, and the end of the first elongated hole 211 close to the node of the frame structure is used as the first end ( Figure 4a the right end in ), and the other end away from the node as the second end ( Figure 4a The left end of the center), the diameter of the first elongated hole 211 gradually increases from the first end to...

Embodiment 2

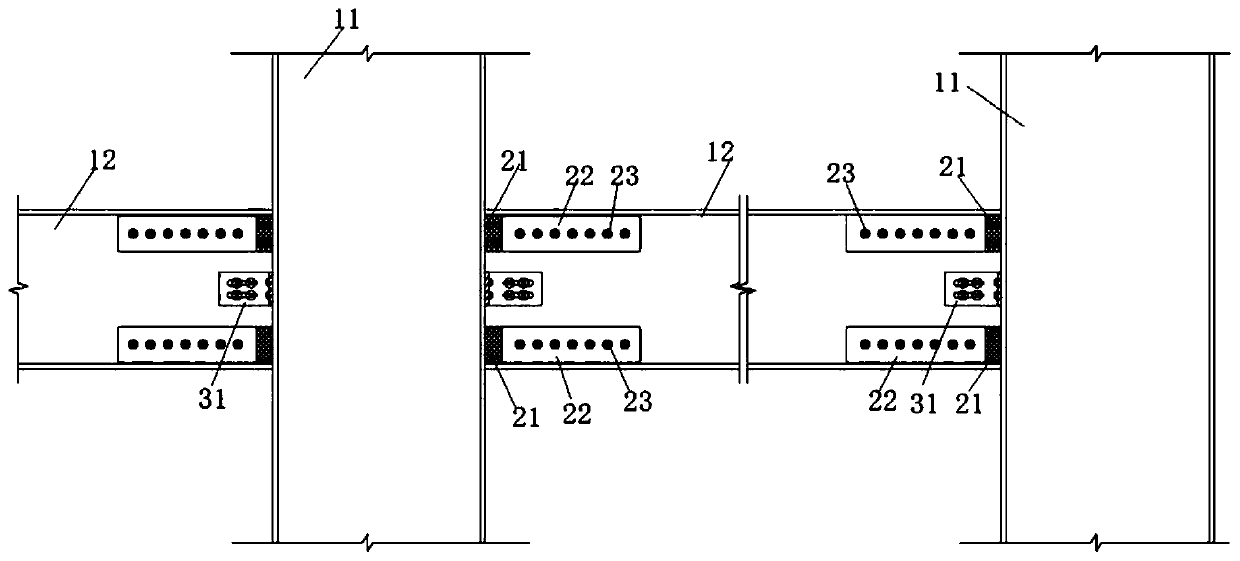

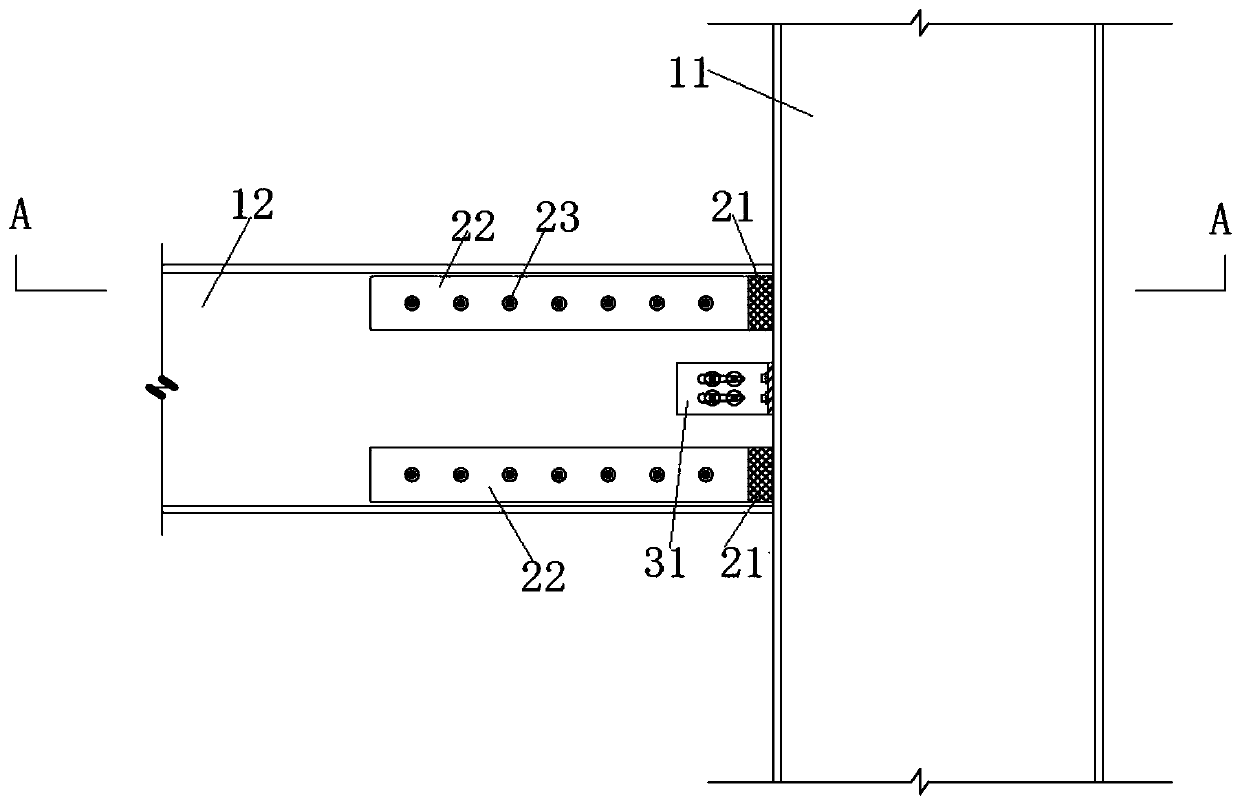

[0076] This embodiment provides a building frame structure, such as figure 1 and figure 2 As shown, it includes at least two frame columns 11 , at least one frame beam 12 and at least two friction dampers provided by any one of embodiment 1.

[0077] Wherein, a plurality of frame columns 11 are arranged vertically and horizontally at intervals; each frame beam 12 is arranged horizontally between two adjacent frame columns 11; The frame columns 11 are connected. for example, figure 1 Two friction dampers are respectively used to connect one end of the frame beam 12 with its adjacent frame column 11 .

[0078] In the building frame structure of this embodiment, since the nodes of the frame beam 12 and the frame column 11 are fixedly connected by using the friction damper in Example 1, the building frame structure has the performance of energy dissipation and function recovery in an earthquake, At the same time, the structure of the building frame structure is compact, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com