Intermittent forward and reverse barring gear driven by hydraulic cylinder

A cranking device, intermittent technology, applied in the direction of transmission device, fluid transmission device, belt/chain/gear, etc., can solve the problem of axial thermal expansion sensitivity, only one-way automatic cranking, and cannot provide more accurate cranking Angle and other problems, to achieve the effect of precise control of rotation angle and precise turning angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

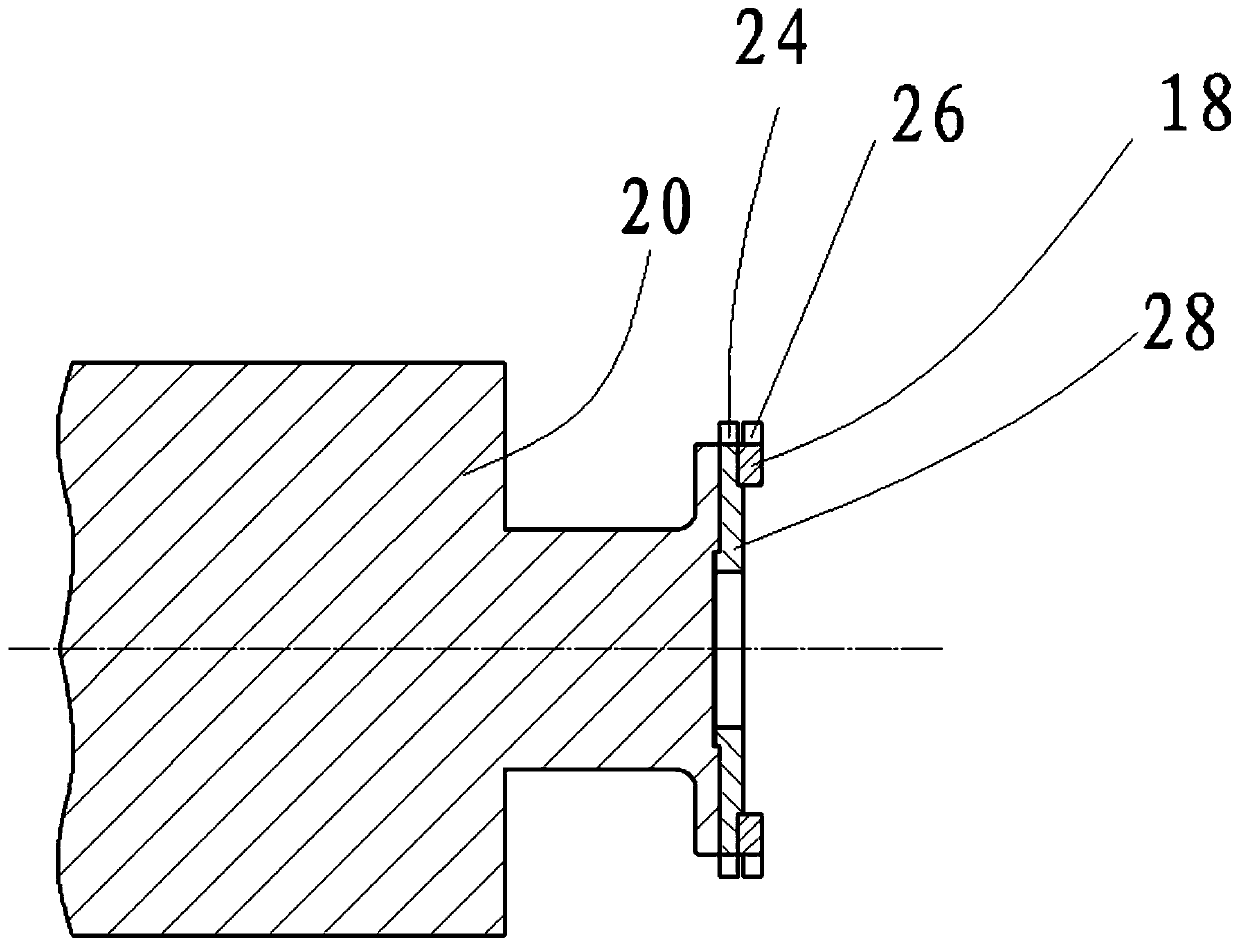

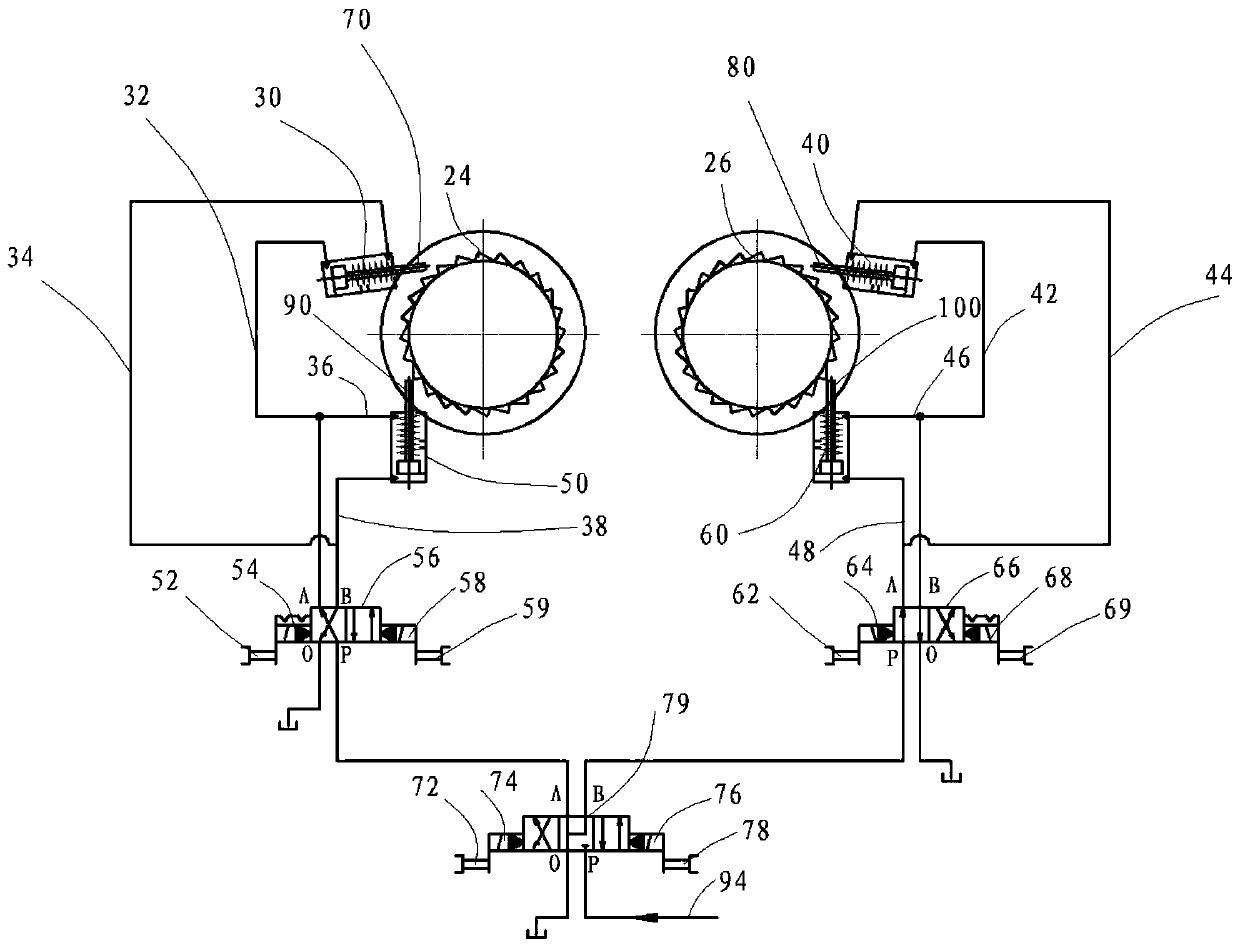

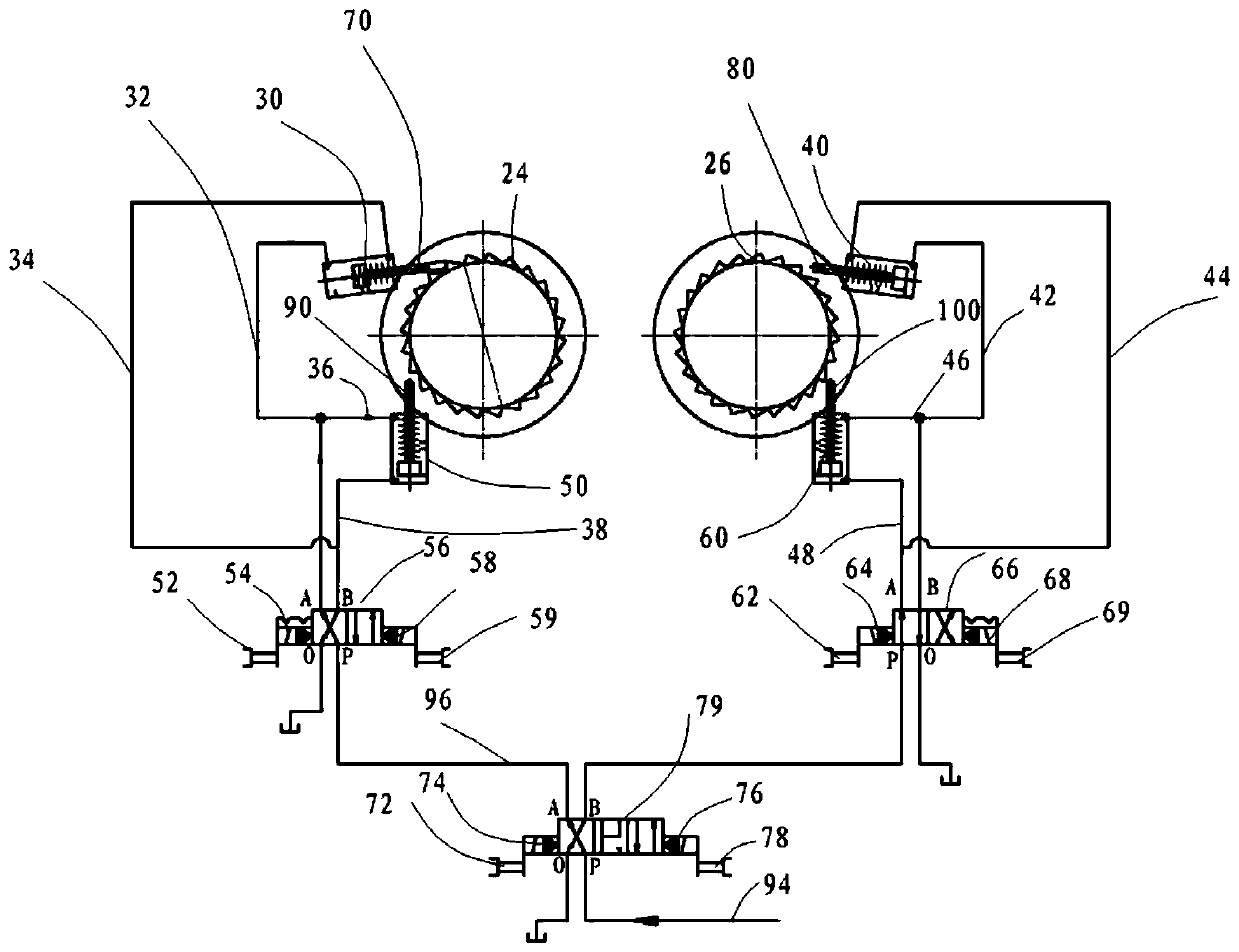

[0014] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a hydraulic cylinder-driven intermittent forward and reverse cranking device described in this embodiment includes a reverse crank gear ring 18, a forward crank gear ring 28, a forward crank oil cylinder I30, a reverse gear Barring cylinder I40, forward cranking cylinder II50, reverse cranking cylinder II60, forward cranking electromagnetic reversing valve 56 and reverse cranking electromagnetic reversing valve 66, forward cranking gear ring 28 and reverse cranking The gear ring 18 is coaxially fixed on the rotor shaft 20, the outer circumferential side wall of the forward gear ring 28 is provided with forward gear teeth 24 along the circumferential direction, and the outer circumferential side of the reverse gear ring 18 The wall is provided with the reverse disc gear 26 along the circumferential direction, the gear tooth working surface inclination direction of the forward disc g...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination Figure 1 to Figure 2 This embodiment will be described. The forward gear ring 28 and the reverse gear ring 18 in this embodiment are fixedly connected to the rotor shaft 20 through a plurality of connecting bolts respectively. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 2 To illustrate this embodiment, the forward cranking cylinder piston rod I70 of the forward cranking cylinder I30 and the forward cranking cylinder piston rod II90 of the forward cranking cylinder II50 in this embodiment act on the forward cranking cylinder respectively when extending out. On the gear tooth working surface of tooth 24, the reverse crank cylinder piston rod I80 of the reverse crank cylinder I40 and the reverse crank cylinder piston rod II100 of the reverse crank cylinder II60 respectively act on the reverse crank The tooth face of tooth 26. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com