Method for measuring three-dimensional roughness of concrete surface

A concrete surface and measurement method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of limited dimensions, difficult detection of concrete roughness, low precision, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

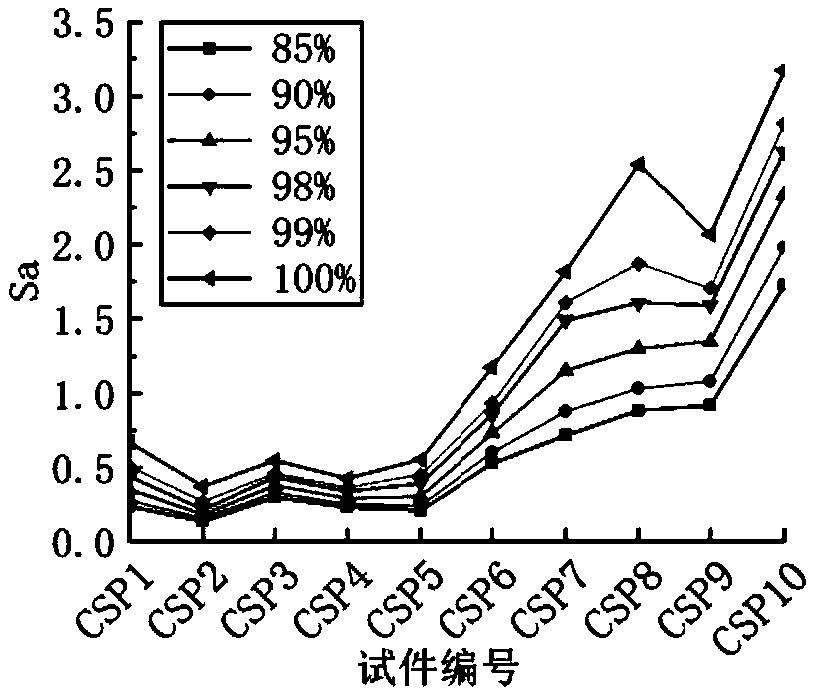

[0050] This embodiment provides a method for measuring the three-dimensional roughness of a concrete surface, comprising the steps of:

[0051] (1) Conduct a 3D scanning test on the object to be tested, and export the file data as source.stl and source.dxf formats after scanning;

[0052] The 3D scanning test is as follows: start the Dr.PICZA3 software on the desktop, click the green SCAN button, select surround scanning, set the scanning surface to 4, set the height and width to 100mm and 150mm respectively according to the CSP standard model size, and set the scanning accuracy to 0.2 mm, to ensure the accuracy of the 3D scanning test; to ensure that the object to be tested is completely scanned, click Preview to preview, and adjust the parameter settings through the small window; after the parameter settings are completed, click Scan to scan....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com