PLC safety monitoring and dynamic measurement method and system

A measurement method and measurement system technology, applied in the field of PLC security real-time monitoring and measurement, can solve the problems of lack of protection, CPU is easy to be attacked at the same time, and cannot be detected, so as to strengthen security protection, prevent PLC security problems, The effect of high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

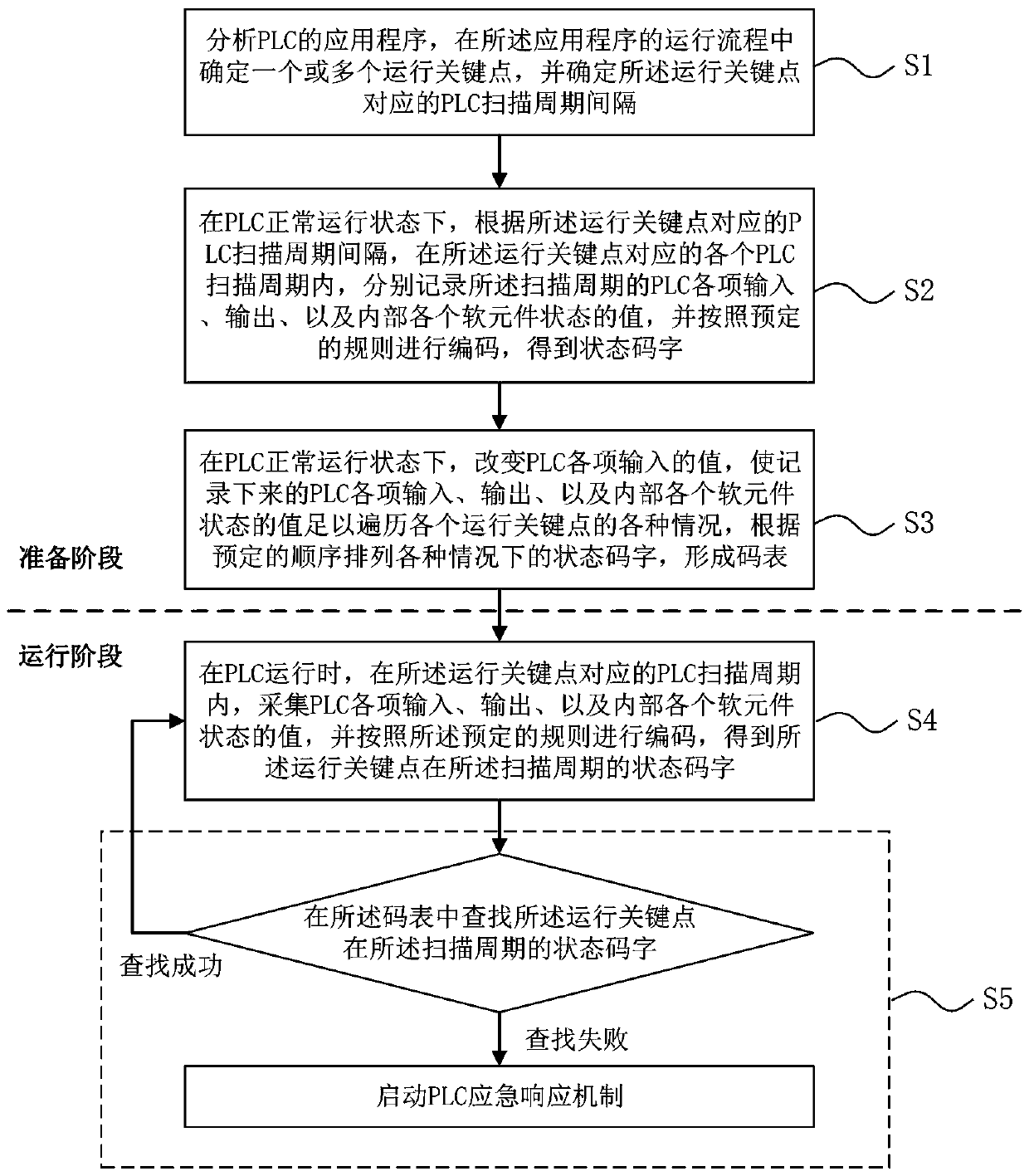

[0034]This embodiment provides a PLC security real-time monitoring and measurement method, such as figure 1 As shown, the method includes the following steps:

[0035] Preparation Phase

[0036] S1. Analyzing the application program of PLC, determining one or more operation key points in the operation process of the application program, and determining the PLC scan cycle interval corresponding to the operation key points;

[0037] S2. In the normal operation state of the PLC, according to the PLC scan cycle interval corresponding to the key point of operation, in each PLC scan cycle corresponding to the key point of operation, record the PLC input, output, and output of the scan cycle respectively. And the value of each internal soft component state, and encode according to the predetermined rules to obtain the state code word;

[0038] S3. In the normal operation state of the PLC, change the values of the various inputs of the PLC, so that the recorded values of the var...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that another method for encoding according to predetermined rules described in step S2 and step S4 is provided, including: inputting, outputting, and The value of each soft component state inside the PLC is written in binary form according to the predetermined rules, and placed in the predetermined binary code position, combined to form a binary code word, after adding a check code in the binary code word, as a code The following status codeword.

[0054] Check codes include parity check codes, Hamming check codes, cyclic redundancy codes (CRC codes), and the like. The check code enables the encoding method to have certain error detection and even error correction capabilities. For the failure of looking up the status codeword in the code table, that is, in the case of abnormality, it is helpful to find out which part the problem lies in.

Embodiment 3

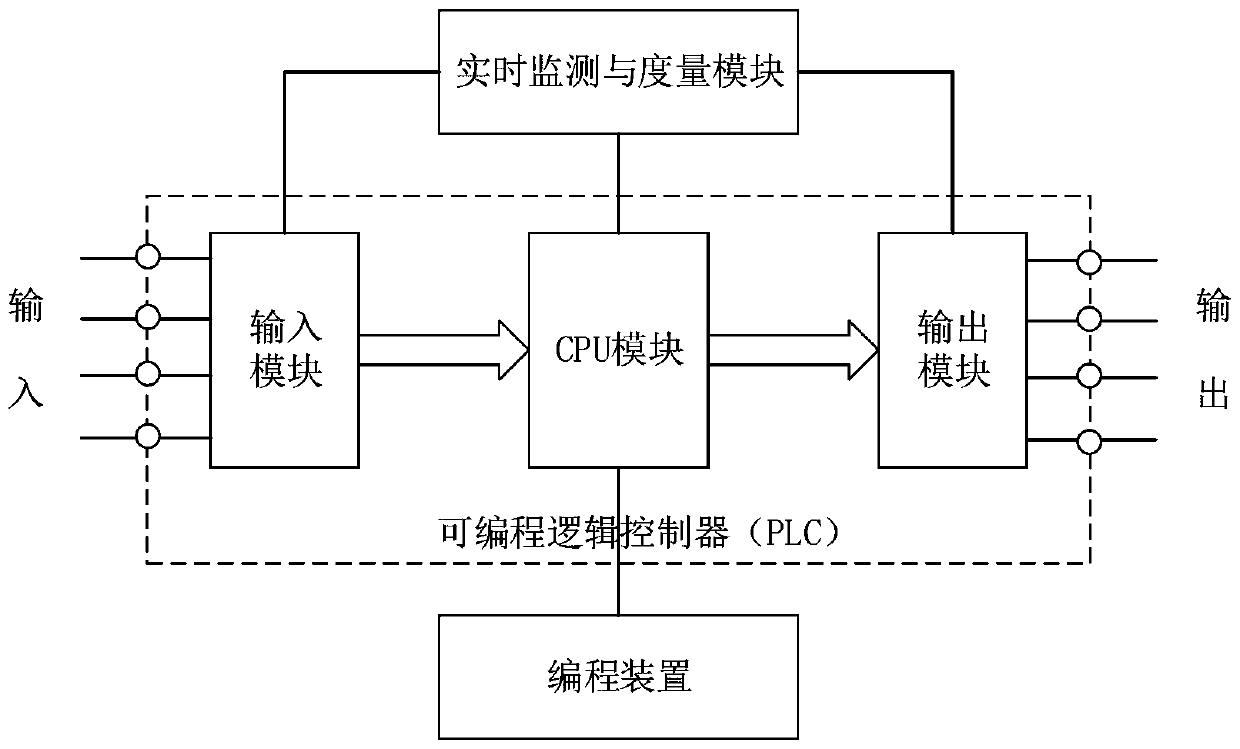

[0056] Based on the same inventive concept as the above method, this embodiment provides a PLC safety real-time monitoring and measurement system, such as figure 2 As shown, the system includes a real-time monitoring and measurement module, and the real-time monitoring and measurement module is connected with the CPU module, the input module and the output module of the PLC respectively;

[0057] In the preparatory stage, at first, by analyzing the application program of PLC, determine one or more operation key points in the operation process of the application program, and determine the PLC scanning cycle interval corresponding to the operation key point; the real-time monitoring and measurement When the module is in the normal running state of the PLC, according to the PLC scan cycle interval corresponding to the key point of operation, in each PLC scan cycle corresponding to the key point of operation, record the various inputs, outputs, and internal parameters of the PLC i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com