Crop discharge control for forage harvester

A crop and controller technology, applied in harvesters, control/regulation systems, applications, etc., to achieve the effect of improving placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

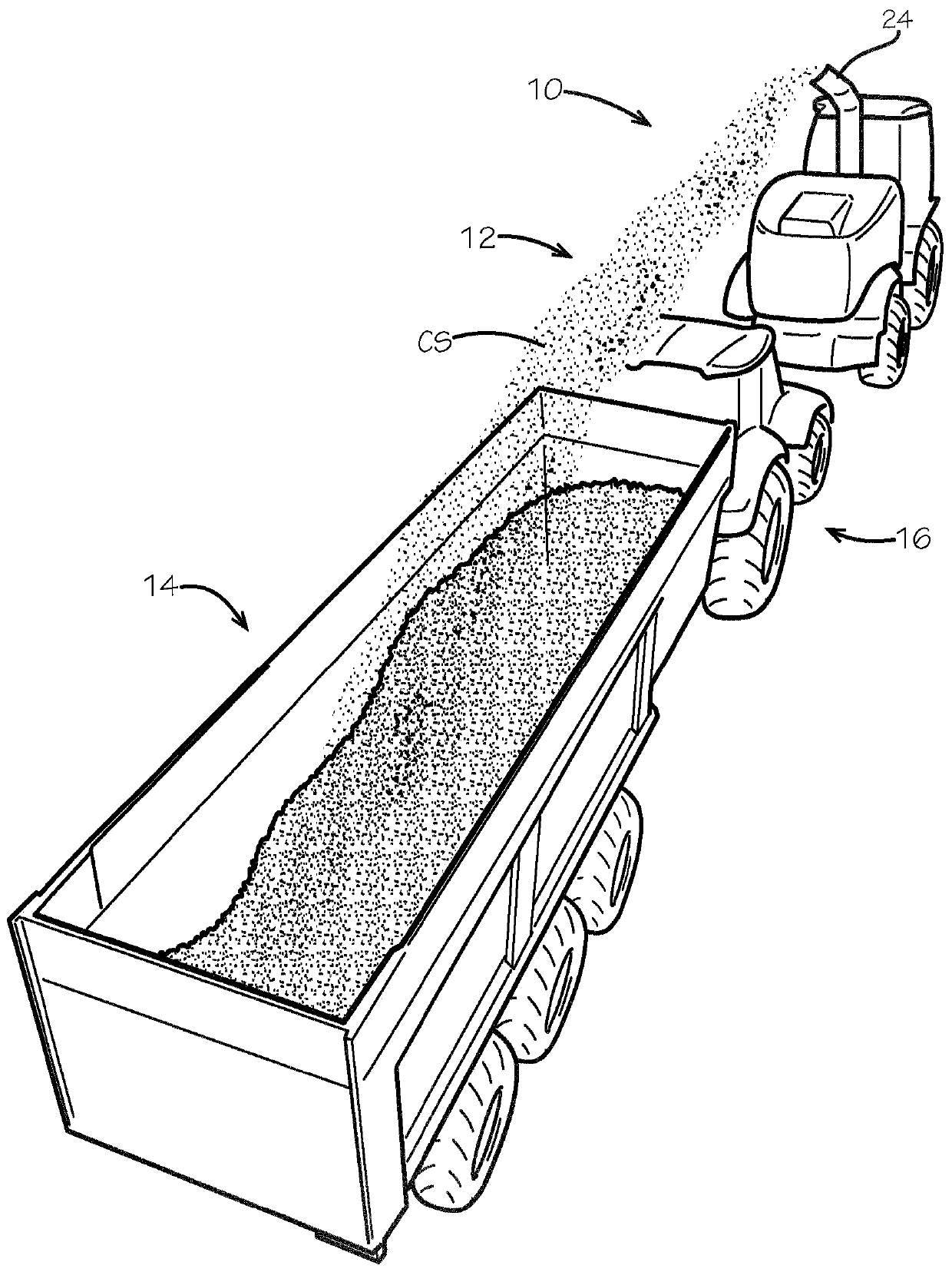

[0038] Referring now to the accompanying drawings, and more particularly to figure 1 , shows an exemplary embodiment of a harvesting vehicle 10 in the form of a forage harvester 10 that directs a crop stream CS along a crop trajectory 12 to a receiving vehicle 14 towed by a tractor 16 .

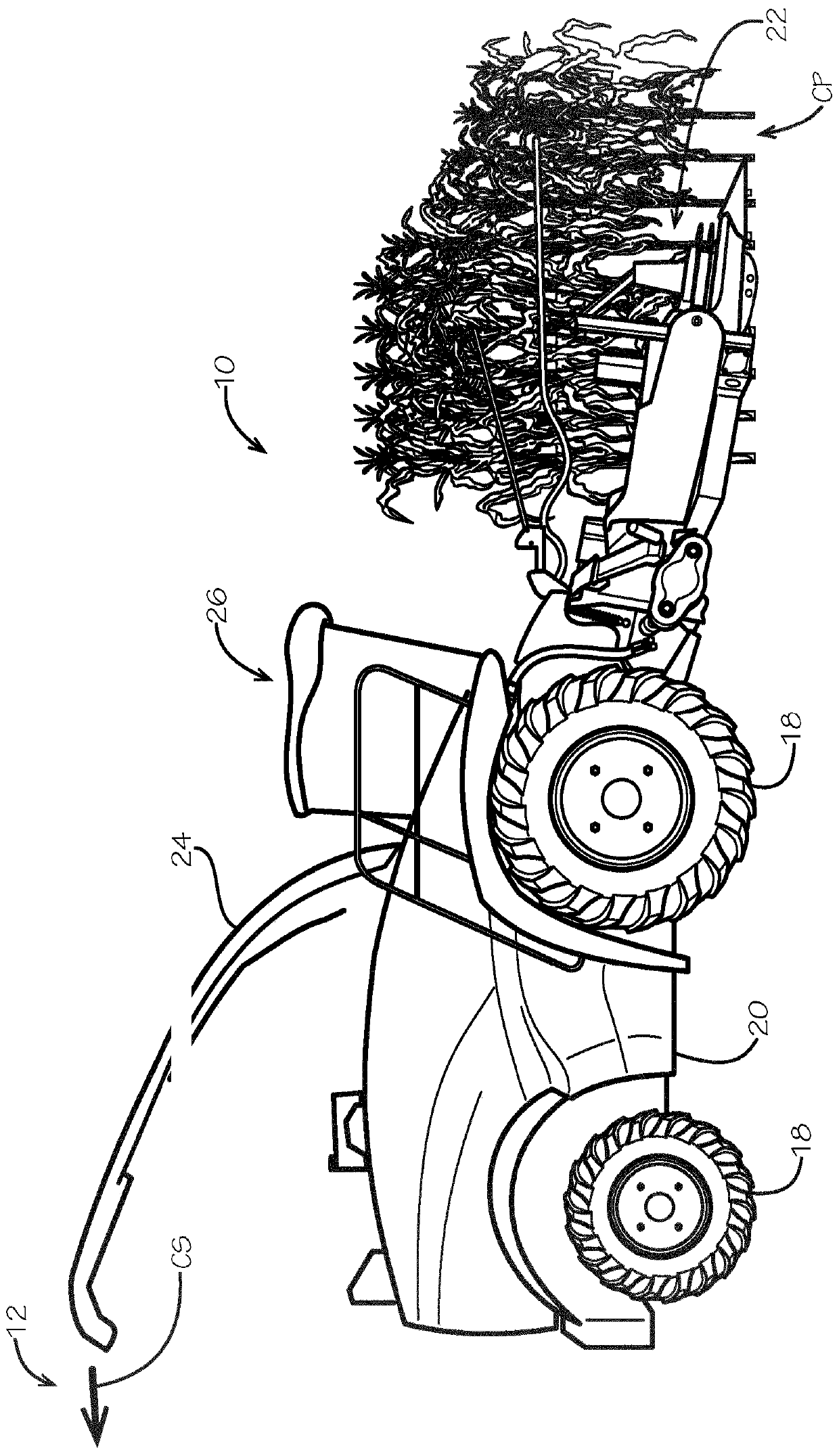

[0039] Now, again refer to figure 2 , shows a side view of forage harvester 10 having wheels 18 , chassis 20 , header 22 , spray tube 24 and operator cab 26 . The wheels 18 carry a chassis 20 in which in turn a header 22 is supported. Heading deck 22 is selected to harvest—ie, cut and gather—crop CP from the field as forage harvester 10 travels in a forward direction. Harvested crops are processed and cut into small pieces for storage in silos and eventual feeding to livestock. Crop stream CS is directed along trajectory 12, as figure 1 The longitudinal direction in is shown in the rearward direction for efficient and uniform loading of the receiving vehicle 14 by sending the crop stream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com