Side position and bottom edge enhanced large cup structure and novel bra

An enhanced, large-cup technology, applied in bras, clothing, applications, etc., can solve the problems of easy movement, poor comfort, poor concentration, etc., and achieve the effect of enhancing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

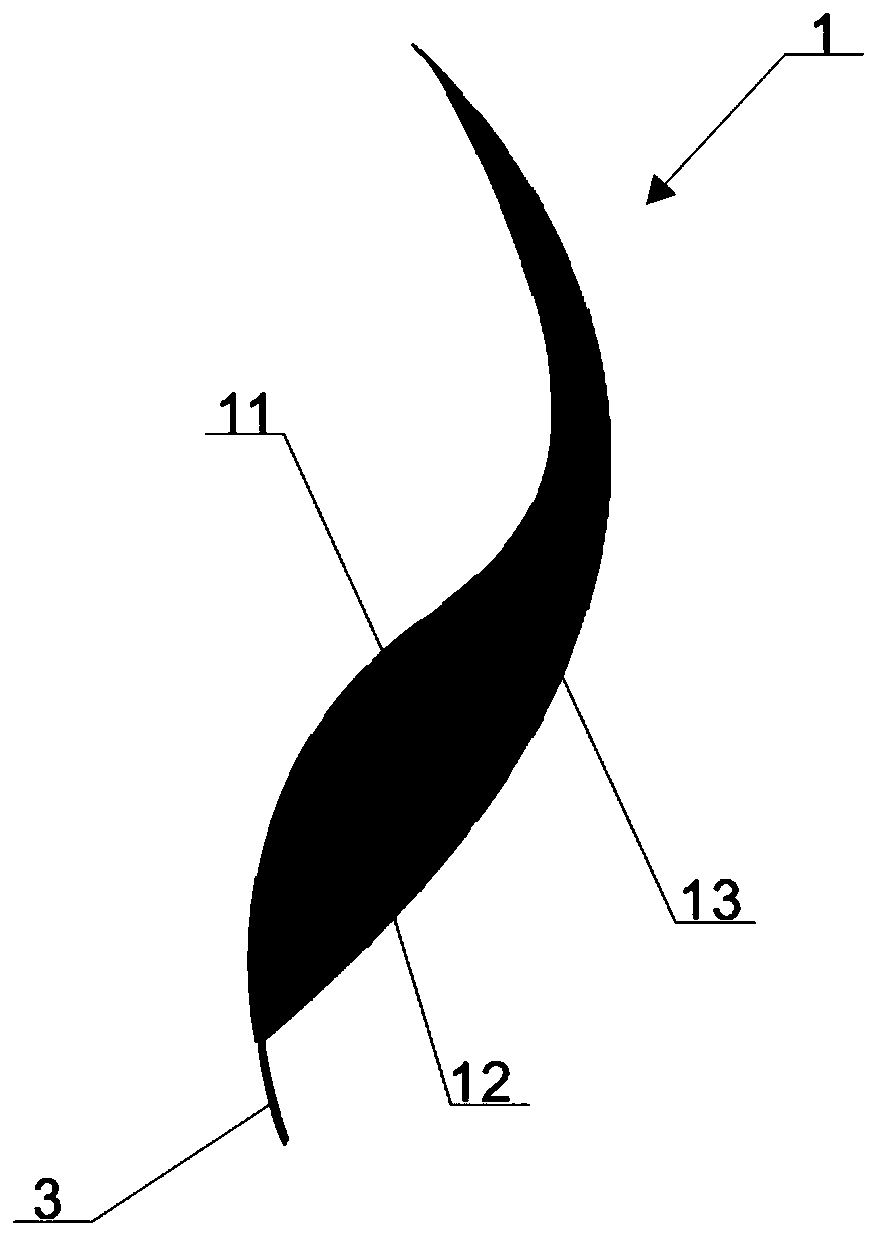

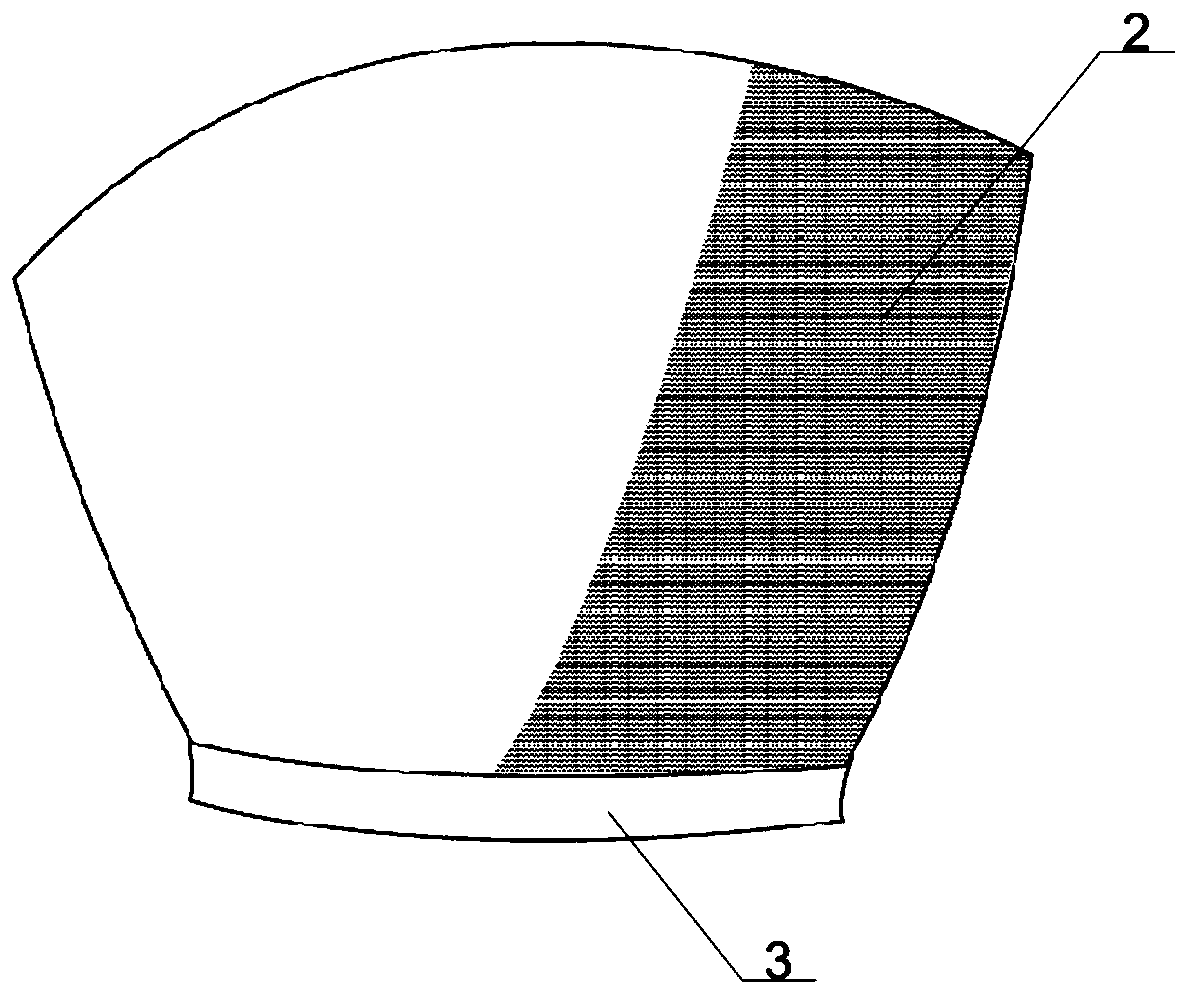

[0023] This embodiment provides a side, bottom edge reinforced large cup structure, such as Figure 1-2 As shown, the cup includes a cup body 1, a mesh fabric 2 and a support portion 3. The mesh fabric 2 is molded inside the cup body 1 corresponding to the side area of the cup. The inner side of the mesh fabric 2 is a latex layer 11 and a core sponge layer 12 so that the mesh fabric It will not directly act on the wearer's chest, so as to provide moderate flexible support to the inside through the cushioning layer; the support part 3 is a rubber strip with a preset width made of plastic material, and the rubber strip is set corresponding to the bottom edge of the cup and molded integrally Fixed between the core sponge layer 12 and the outer sponge layer 13, the inner and outer sides of the rubber strip integrally molded with the cup body 1 are covered with latex or sponge layers. The rubber strip is divided into upper and lower parts. The material of the rubber strip has suff...

Embodiment 2

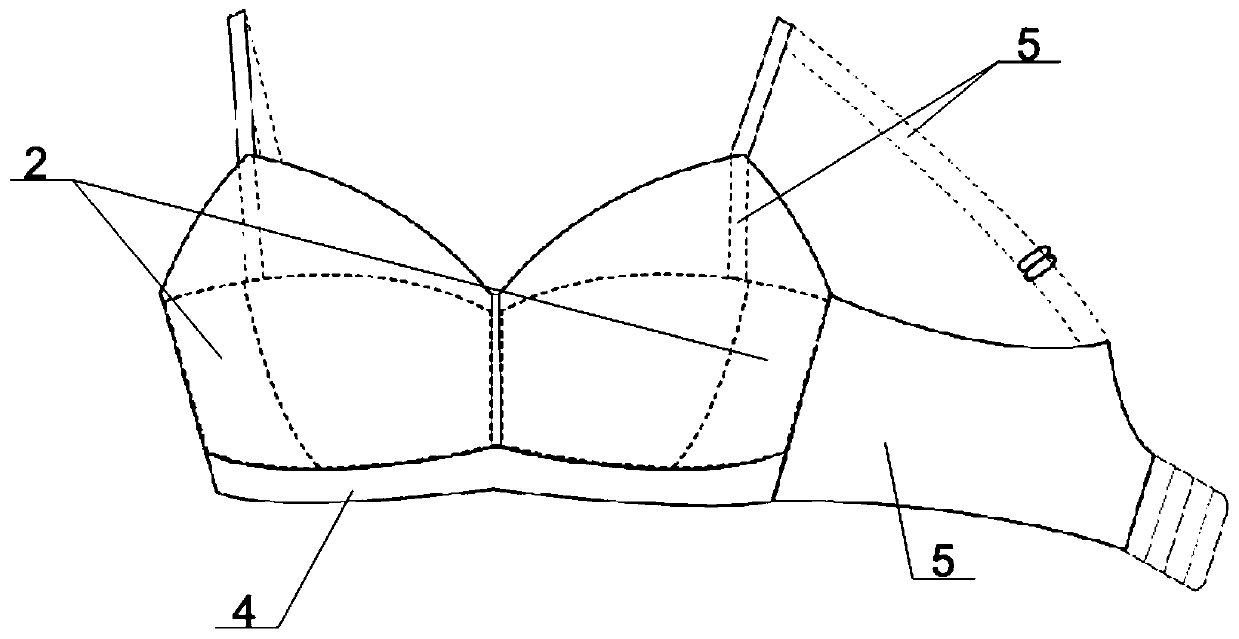

[0027] On the basis of Embodiment 1, this embodiment also provides a new type of bra with the side and bottom edge reinforced large cup structure. This bra has no side ratio, no chicken heart, no steel ring, simple structure, and is suitable for a wide range of people. , especially suitable for people with large busts, the specific structure is as follows image 3 As shown, it includes two cups, soil platform 4, two shoulder straps 5 and two rear ratios 6. The opposite front and middle edges of the two cups are directly connected and there is no heart between them, and the side edges of the two cups are respectively connected to the rear ratio 6. , the highest point of the top edge of the two cups is provided with ears, the soil platform 4 is connected with the lower edge of the two cups and connected with a rubber strip by integral sewing, one end of the shoulder strap 5 is connected to the ear of the cup, and the other end is connected to the back ratio 6. The design of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com