Heat exchanger pipe inserting platform

A heat exchanger and intubation technology, which is applied in the field of heat pipe insertion devices, can solve the problems of uncontrollability, damage to heat sinks by heat dissipation pipes, and low processing efficiency, so as to increase the range of use, improve the accuracy of intubation, and improve the accuracy of intubation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

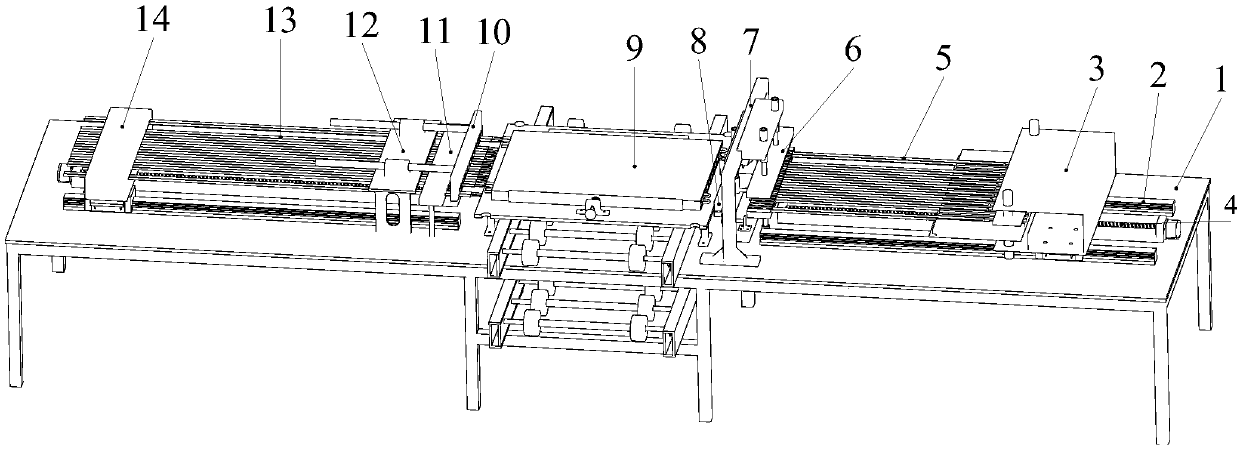

[0029] The invention provides a tube intubation platform in the heat exchanger production process, which is particularly suitable for the automatic batch intubation process of heat dissipation tubes in the finned tube heat exchanger assembly production process. The specific plan is as follows:

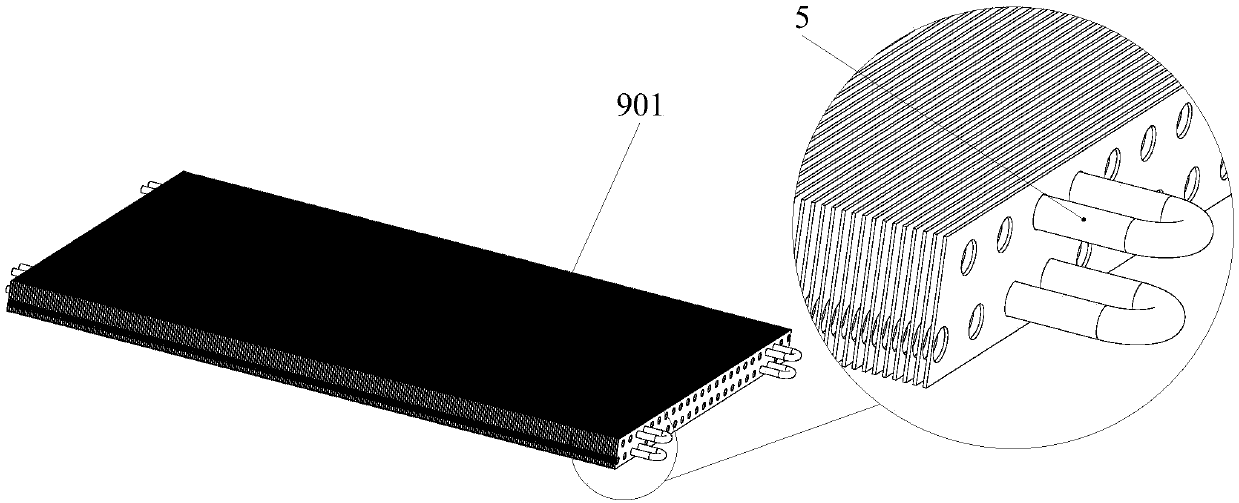

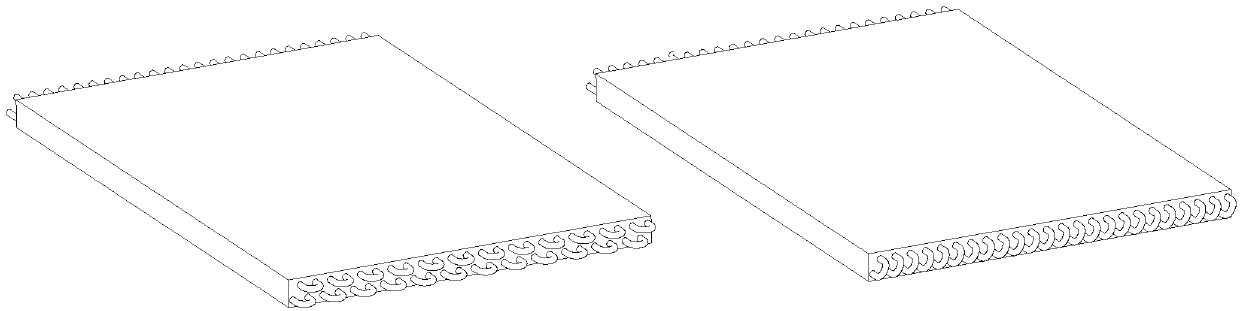

[0030] refer to figure 1 , when the heat exchanger 9 to be intubated is transported to the designated position of the intubation by the guide rail, the positioning needle 13 on the positioning needle seat 14 is inserted into the heat exchanger 9 driven by the lead screw motor guide rail, and at the same time, a row of U-shaped tubes 5 has been placed at the previous station Figure 6 Between the middle pipe groove 304 and the lower tooth plate 602 . Next, the lead screw motor guide rail 4 drives the push tube assembly 3 to move for a certain distance in the direction of the heat exchanger 9 to be intubated. 302 is pressed to the U-shaped tube 5, and cooperates with the tube placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com