Grinding device and grinding method

A grinding device and grinding head technology, applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of uneven hydraulic pressure of the retainer, uneven grinding pressure, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0050] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

[0051] In addition, in this embodiment, the setting process of the grinding conditions (head pressing force, table rotation speed, grinding time) based on the retainer hydraulic pressure is performed for each batch (once in a batch) is exemplified. structure, but it can also be done multiple times in 1 batch.

[0052] [Structure of grinding device]

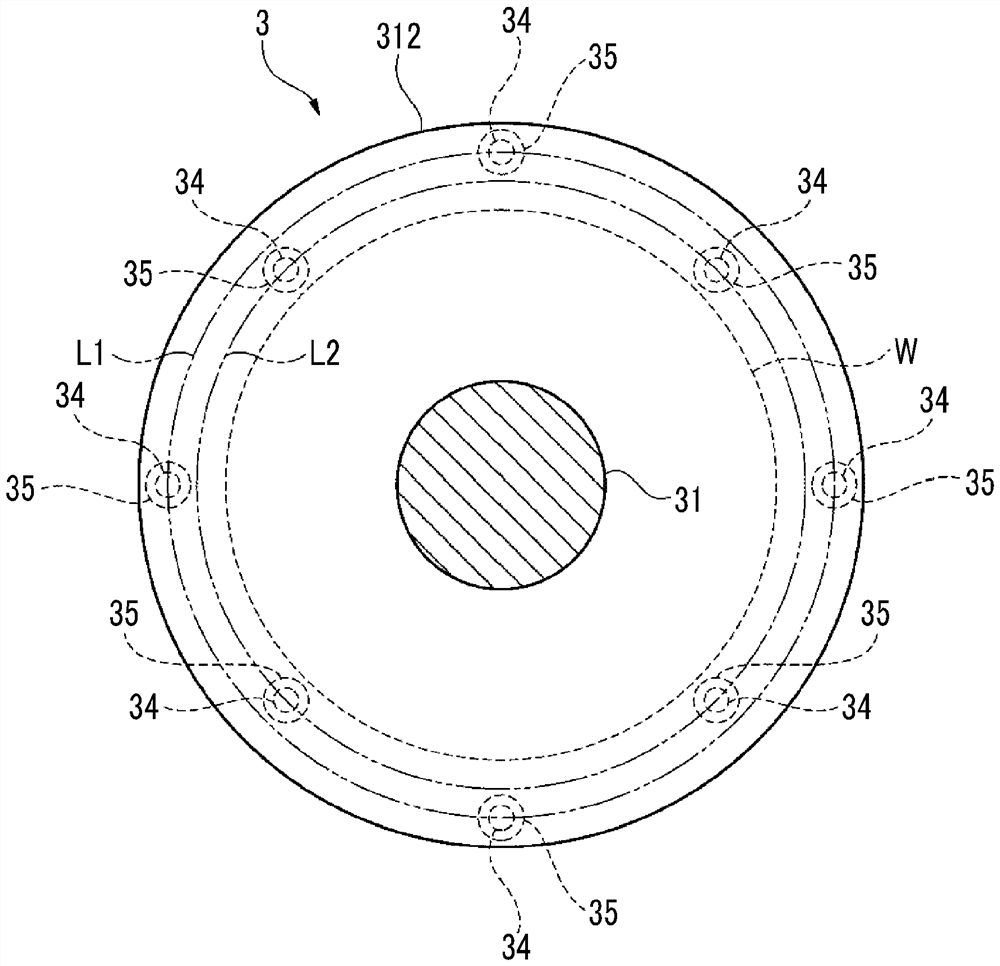

[0053] Such as figure 1 and figure 2 As shown, the polishing device 1 is a single-chip device for finely grinding the surface of a wafer W having a diameter of 300 mm. In addition, the polishing apparatus 1 may be used as a target wafer W whose diameter size is other than 300 mm.

[0054] This grinding device 1 is provided with grinding part 2, four grinding heads 3, grinding head driving mechanism 4 (referring to Figure 5 ), storage mechanism 5 (reference Figure 5 ) and control mechanism 6 (refer to Figur...

no. 2 Embodiment approach

[0106] Next, a second embodiment of the present invention will be described.

[0107] In addition, the major difference between the second embodiment and the first embodiment is the polishing process of the wafer W, and the structure of the polishing apparatus 1 is the same as that of the first embodiment.

[0108] First, if Figure 7 As shown, the polishing control mechanism 61 and the four cage hydraulic pressure measurement mechanisms 35 of the polishing apparatus 1 perform the same processes of steps S1 to S3 as those in the first embodiment.

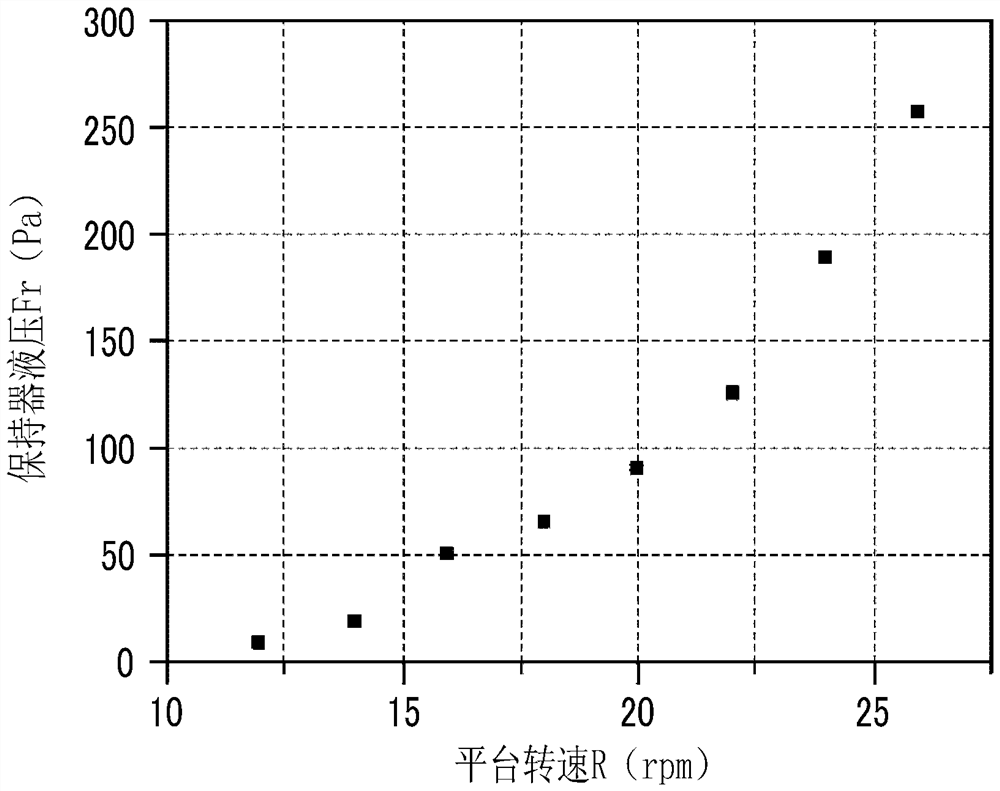

[0109] When the retainer hydraulic pressure measurement results from the four retainer hydraulic pressure measurement means 35 are obtained, the parameter setting means 62 calculates a value related to the inclination of the retainer ring 33 from the four retainer hydraulic pressure Fr (step S14 ).

[0110] The inclination related value is a value indicating the inclination of the lower surface of the holding ring 33 with respect t...

Embodiment approach

[0122] In addition, this invention is not limited to the said embodiment, Various improvement, a design change, etc. are possible in the range which does not deviate from the summary of this invention.

[0123] That is, in the first embodiment, the following configuration can be adopted.

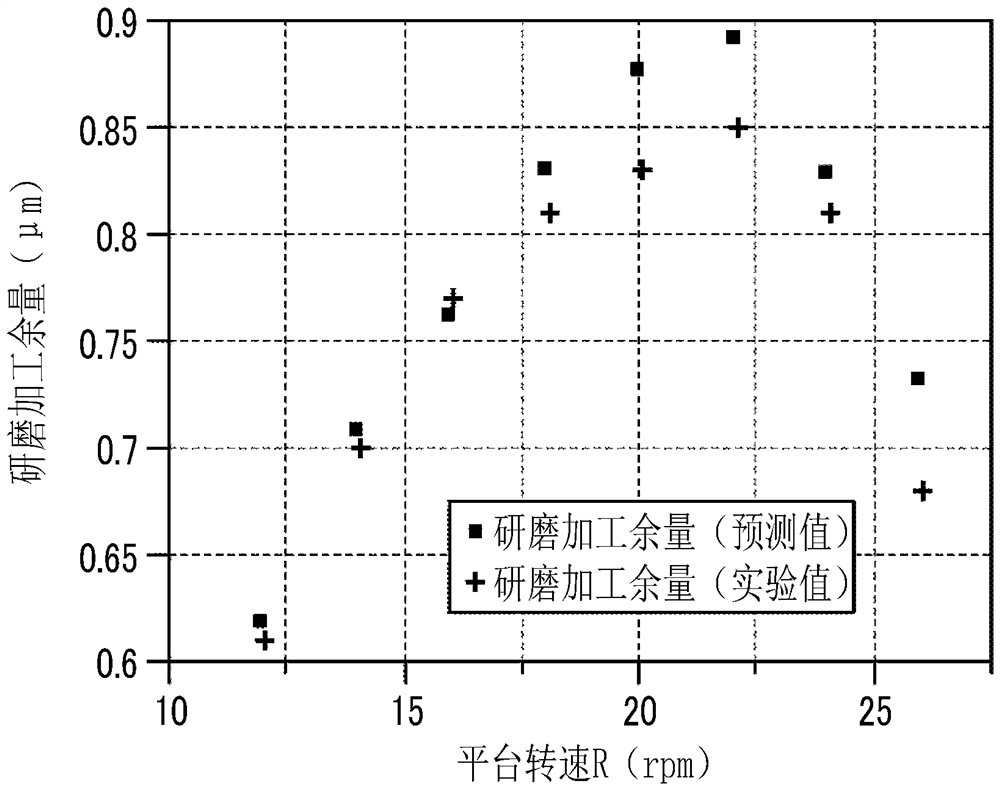

[0124] As the relational expression for calculating the predicted value of the grinding allowance, the above-mentioned mathematical expression (1) is used, but for example, it is also possible to newly introduce a parameter related to the retainer hydraulic pressure Fr, and use the above-mentioned mathematical expression ( 1) Different relational formulas are used to calculate the predicted value of the grinding allowance.

[0125] When the newly measured retainer hydraulic pressure Fr is greater than the retainer hydraulic pressure Fr measured in the immediately preceding batch, at least one parameter among the grinding head pressure Fh, platform speed R, and batch grinding time Tb can only...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com