Contact-free type wood plate quantitative cutting auxiliary device

An auxiliary device and contact-free technology, which is applied in the direction of sawing components, sawing equipment, wood processing equipment, etc., can solve the problems of workers' waist injuries, wood cutting angle deviation, time wasting, etc., to save time and avoid injuries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

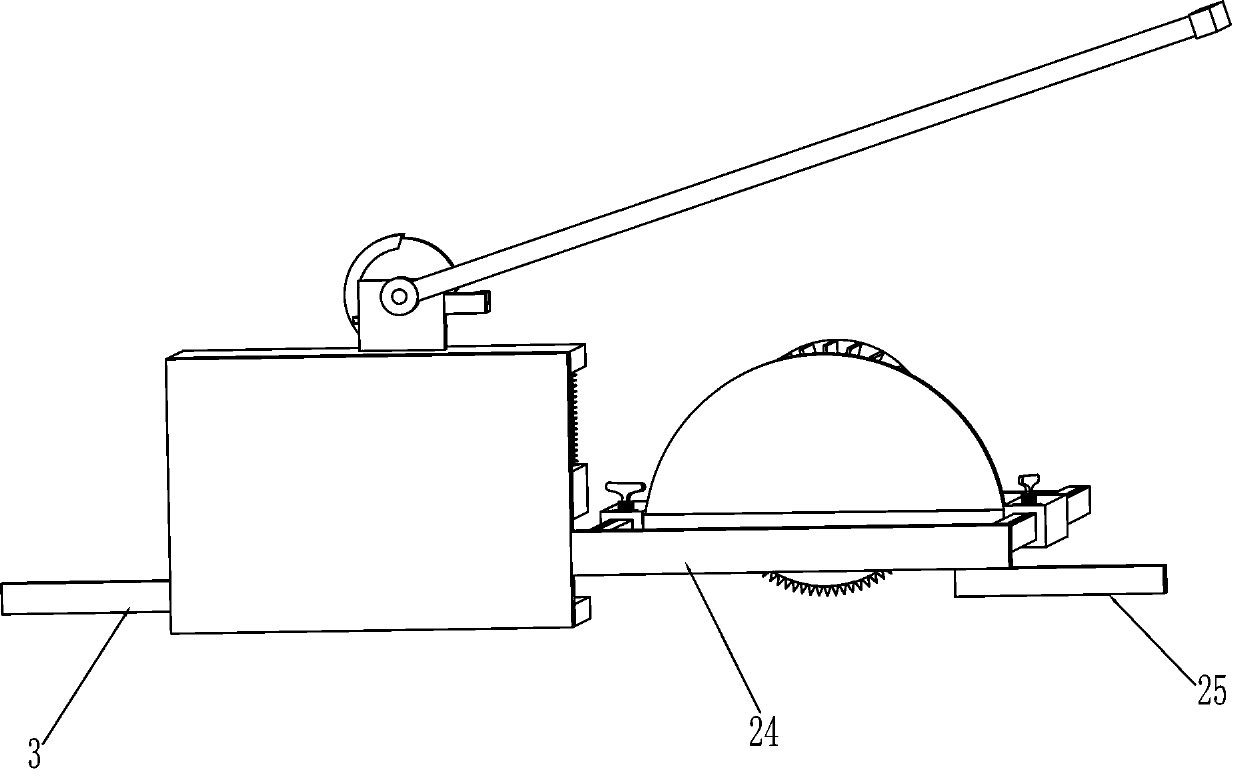

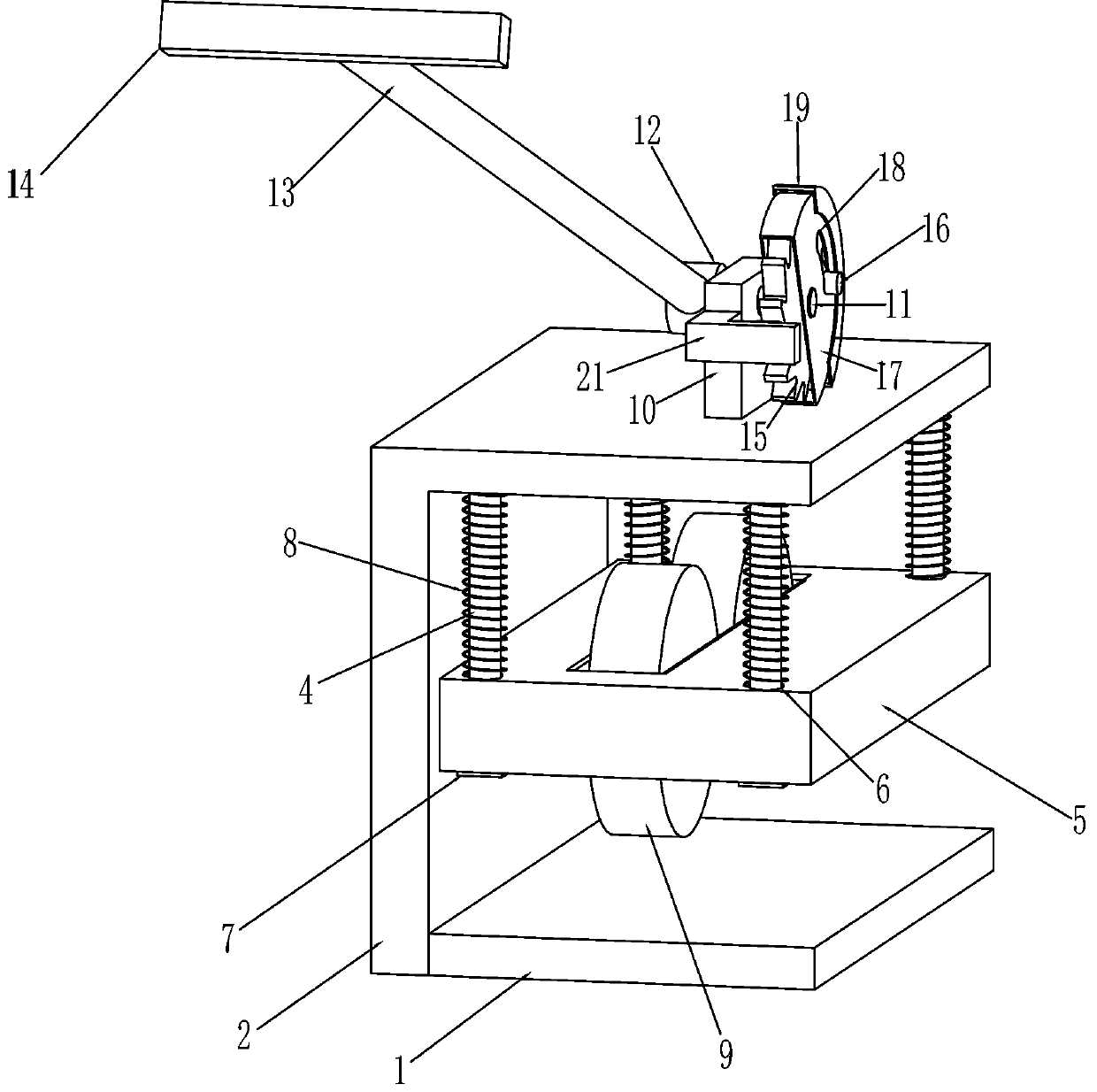

[0022] A non-contact auxiliary device for quantitative cutting of wood boards, see figure 1 , figure 2 and Figure 5 , including a placement board 1, a support board 2, a guide assembly, a push assembly, a mounting rod 24, a support rod 26, a scale 27, a second connecting block 28, a fixed-length assembly and a cutting machine 36, and the right side of the placement board 1 is provided with a support Plate 2, the support plate 2 is provided with a guide assembly, the guide assembly is provided with a push assembly, the installation rod 24 is fixed on the rear side of the support plate 2, and the left side of the installation rod 24 is symmetrically provided with a support rod 26. Two support rods 26 Scale 27 is provided on the top, and the second connection block 28 is connected between the two support rods 26. The two support rods 26 are slidably provided with a fixed-length assembly, and the fixed-length assembly is provided with a cutting machine 36, which is used for the...

Embodiment approach 2

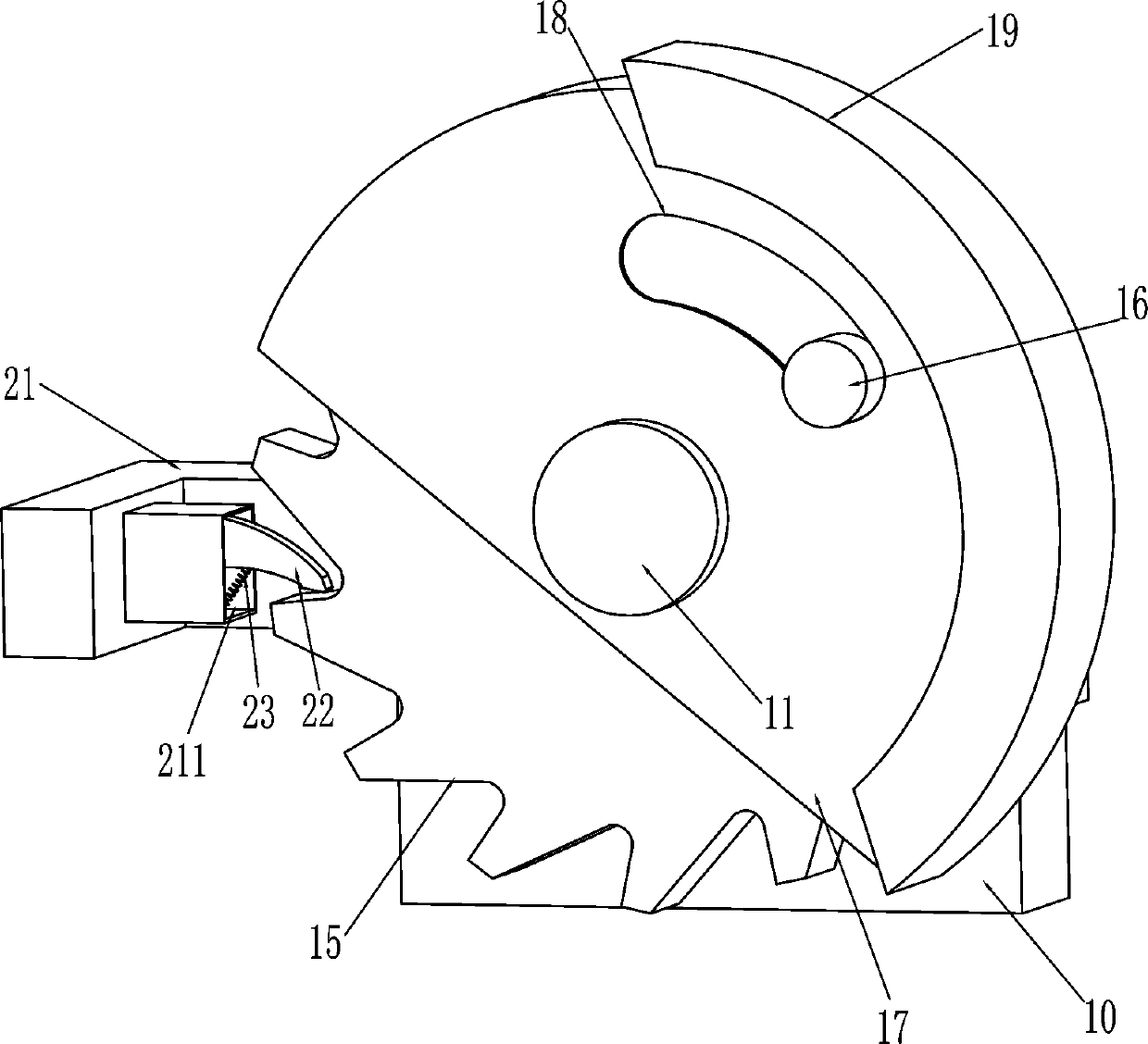

[0025] On the basis of embodiment 1, refer to Figure 1-6 , the guide assembly includes a first guide block 3, a vertical rod 4, a lifting plate 5, a block 7, a first elastic member 8, a roller 9 and a second guide block 25, and the front side of the support plate 2 is provided with a first guide block 3 , the top of the support plate 2 is symmetrically provided with a vertical bar 4 front and back, and the bottom of the vertical bar 4 is provided with a lifting plate 5, and the lifting plate 5 is provided with a through hole 6 symmetrically front and back, the vertical bar 4 passes through the through hole 6, and the bottom of the vertical bar 4 There are stoppers 7, and the four corners of the inner top of the support plate 2 are provided with first elastic parts 8, the first elastic parts 8 are connected with the lifting plate 5, the first elastic parts 8 are wound on the vertical rod 4, and the middle part of the lifting plate 5 rotates The formula is provided with two rol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap