Automatic packaging process for mixed nuts

A technology for automatic packaging and nuts, applied in packaging, packaging machines, transportation and packaging, etc., can solve problems affecting customer experience, low work efficiency, high rework rate, etc., and achieve the effect of saving manual operations and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

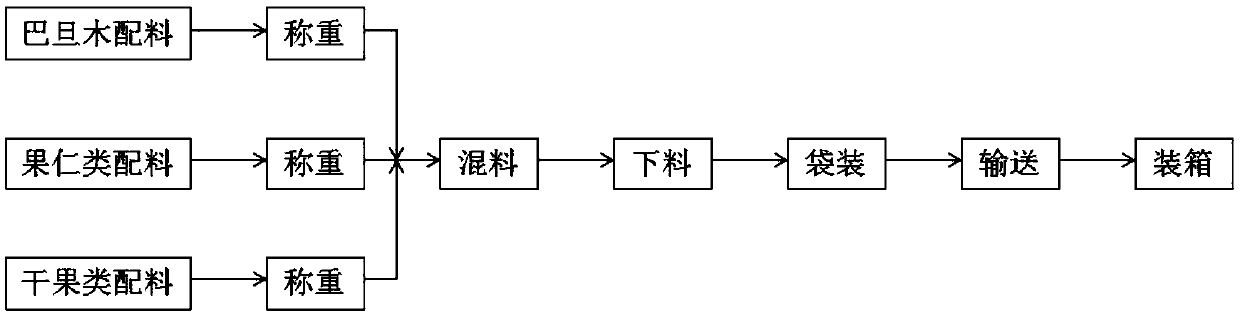

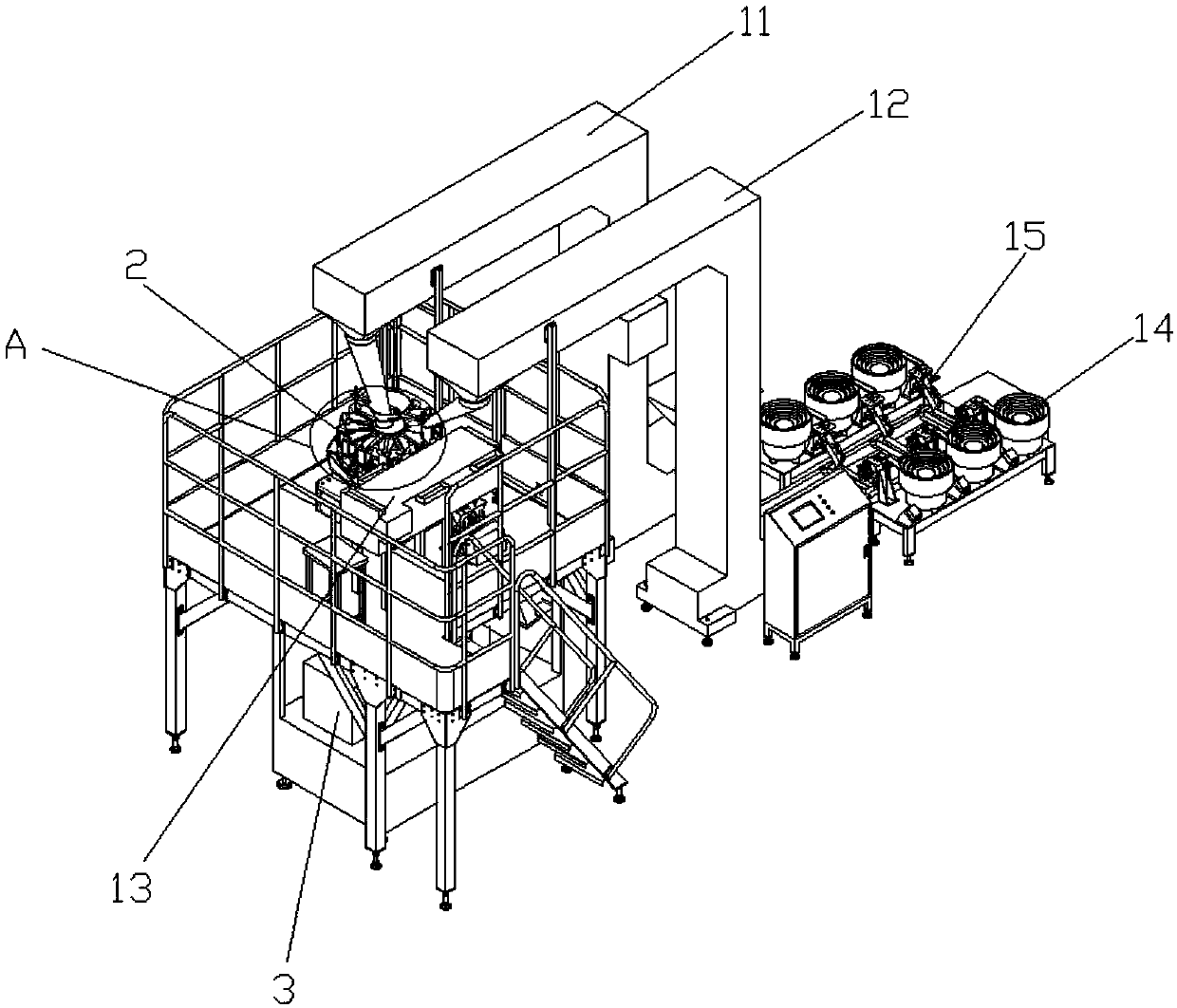

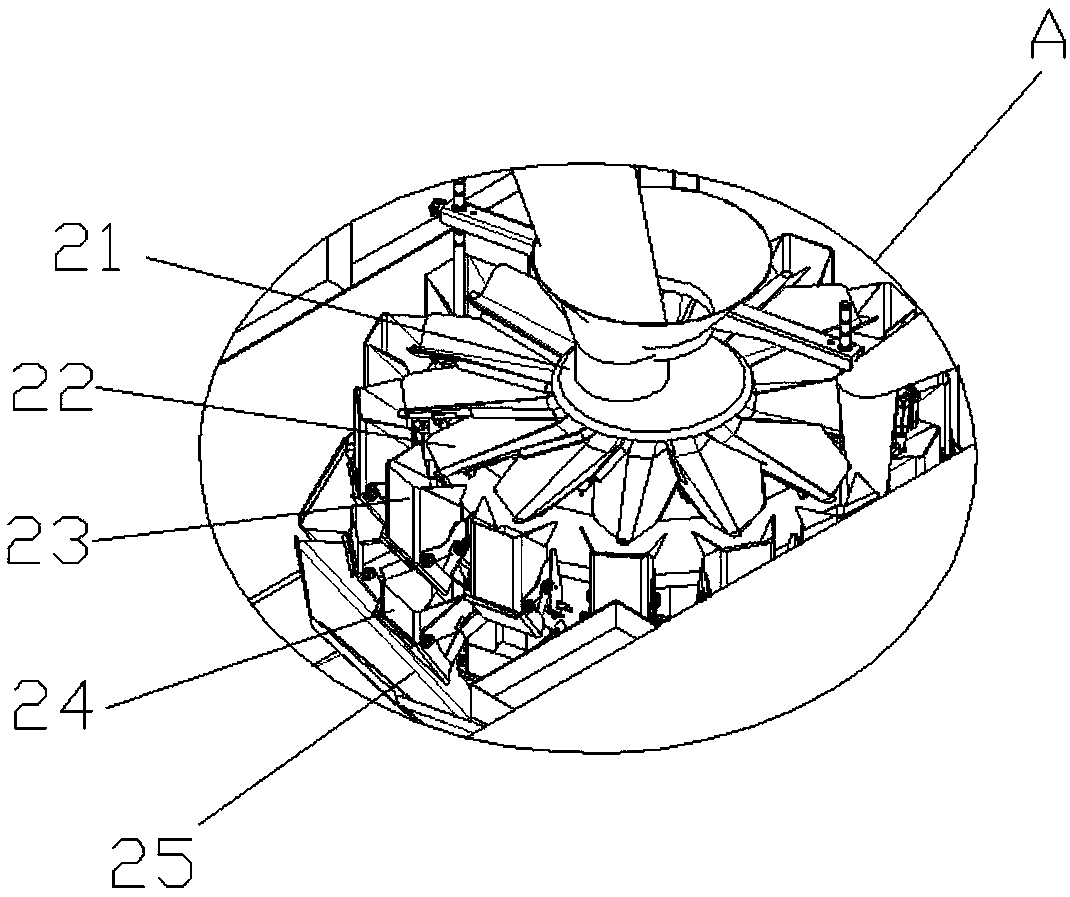

[0021] Such as figure 1 As shown, an automatic packaging process for mixed nuts, including almond ingredients, nut ingredients, dried fruit ingredients, weighing, mixing, packaging, conveying and boxing, such as Figure 2 to Figure 4 As shown, almond ingredients, nut ingredients and dried fruit ingredients adopt mixed nut packaging equipment, and are fed and packaged through three ingredient lines. In the dispersing tray 21, the 11 groups of corresponding radial distributors 22, storage hoppers 23 and weighing hoppers 24 are sequentially passed through, and fall into the guide hopper 25 after being weighed. The nut ingredients include macadamia nuts, Walnut kernels, cashew nut kernels and pistachio nut kernels are fed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com