Double-layer conveying device

A transmission device and double-layer technology, applied in the field of automation, can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

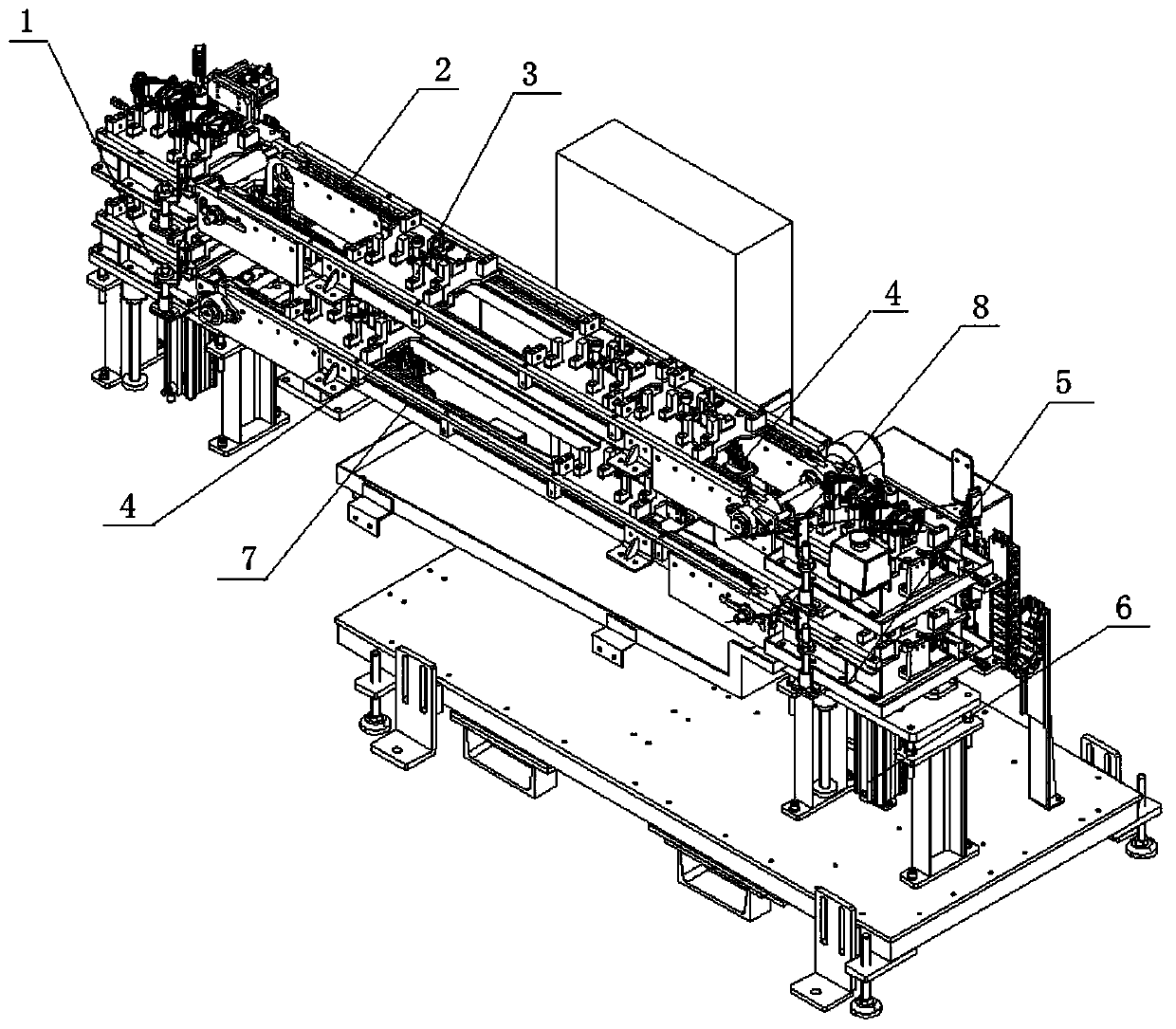

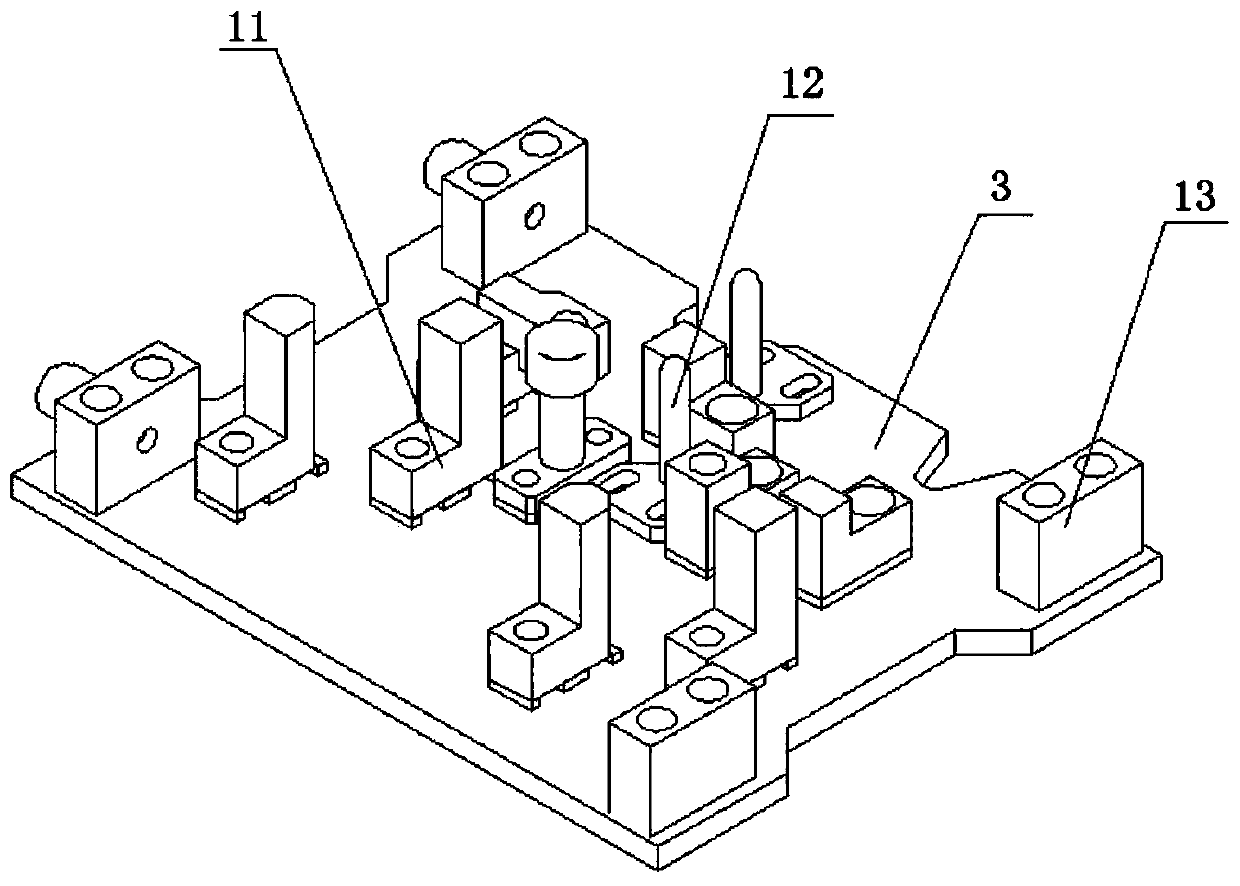

[0020] A double-layer conveying device, comprising two pallet lifting devices 1. A double-layer conveyor belt, the double-layer conveyor belt is set up and down, running in reverse, and a pallet lifting device is installed at both ends of the double-layer conveyor belt.

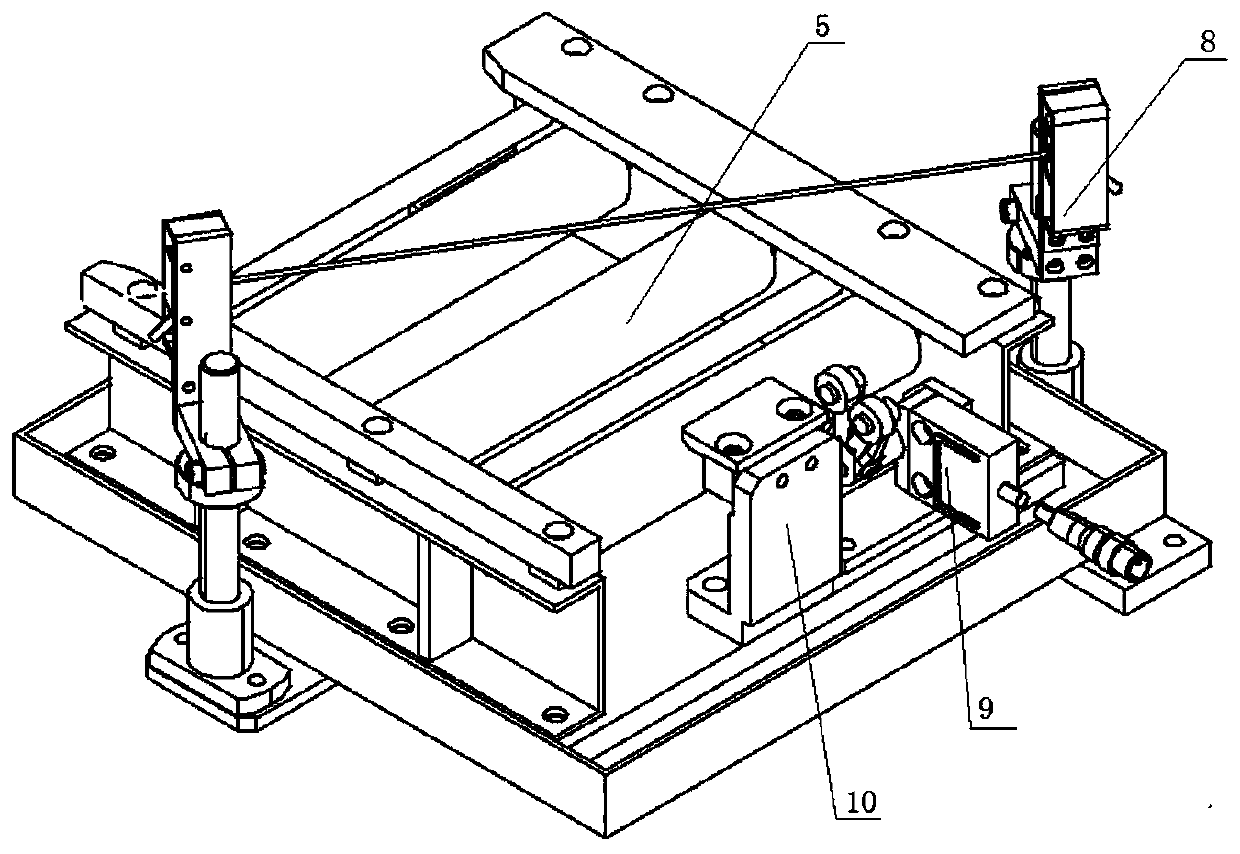

[0021] The pallet lifting device includes a lifting cylinder 6 and an electric drum assembly 5. The lifting cylinder is supported by a bracket with the piston end facing upwards. The electric drum assembly is installed at the piston end, and the tray 3 is placed above the electric drum assembly. A tray positioning block 10 and a tray positioning sensor 9 are installed on one side of the electric drum assembly.

[0022] A pair of through-beam sensors 8 are installed on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com