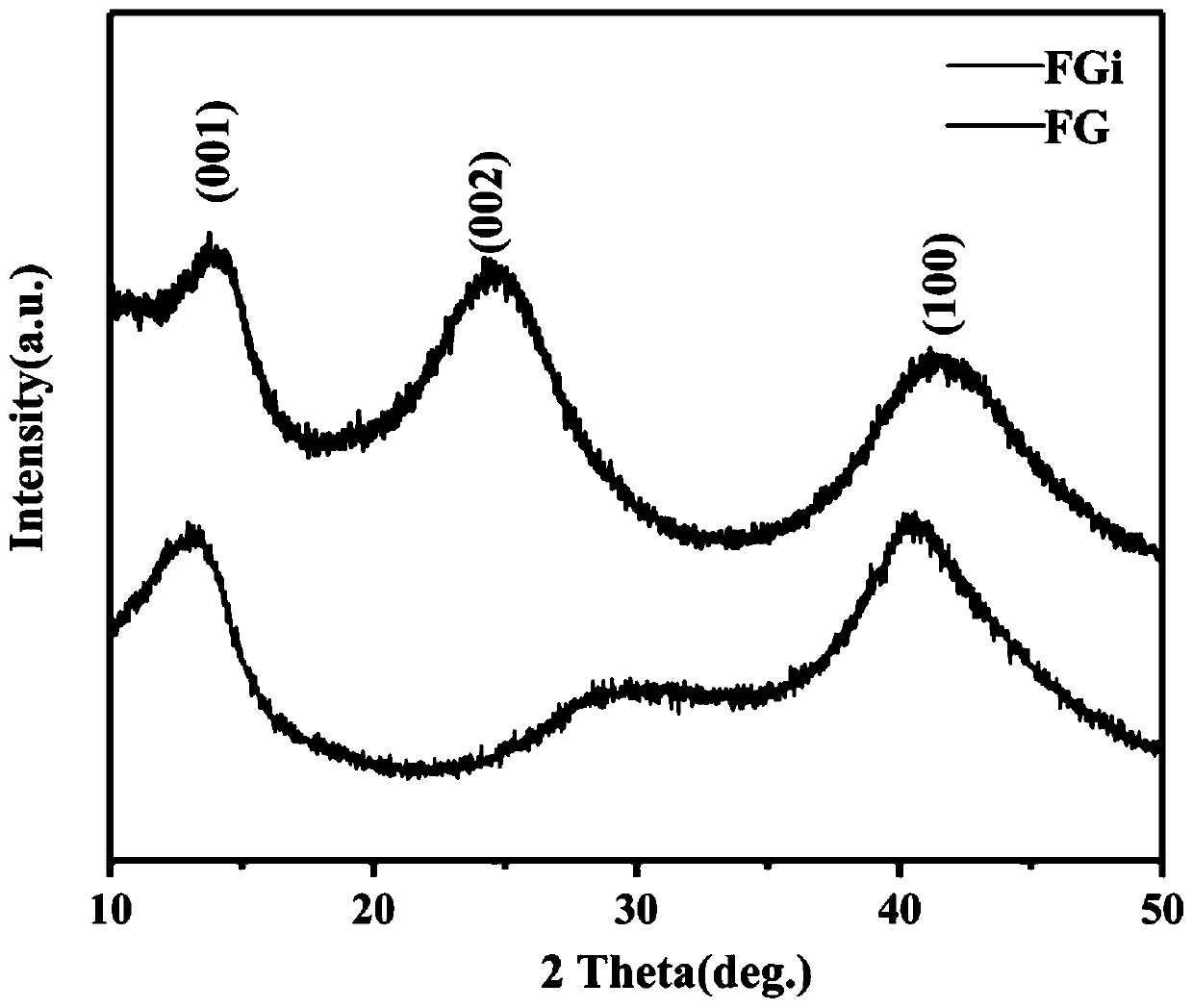

Method for preparing fluorinated graphene dispersion liquid on large scale

A technology of fluorinated graphene and fluorinated graphite, which is applied in the direction of graphene, chemical instruments and methods, carbon fluoride, etc., can solve the problems of easy agglomeration, high yield and high cost, and achieve simple process, low production cost and safety factor high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 1 g of graphite fluoride and 1 g of ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate into 15 ml of deionized water, and sonicate at 40 W for 30 min.

[0025] The mixture was placed in a hydrothermal reactor and reacted at 150°C for 24h.

[0026] The resulting mixture was centrifuged at 2000 rpm for 20 min, and the supernatant of the upper 1 / 2 was collected. Then add 15ml of deionized water, continue to centrifuge at 2000rpm for 20min, and this process is repeated 5 times. The finally obtained dispersion is the fluorinated graphene dispersion of Example 1.

Embodiment 2

[0028] Mix 1 g of graphite fluoride and 1 g of ionic liquid 1-hexadecyl-3-methylimidazole bromide into 15 ml of deionized water, and sonicate at 60 W for 60 min.

[0029] The mixture was placed in a hydrothermal reactor and reacted at 200°C for 20h.

[0030] The resulting mixture was centrifuged at 3000 rpm for 15 min, and the supernatant of the upper 1 / 2 was collected. Then add 15ml of deionized water, continue to centrifuge at 3000rpm for 15min, and this process is repeated 6 times. The finally obtained dispersion is the fluorinated graphene dispersion of Example 2.

Embodiment 3

[0032] Mix 1 g of graphite fluoride and 1 g of ionic liquid 1-dodecyl-3-methylimidazolium tetrafluoroboric acid into 15 ml of deionized water, and sonicate at 80 W for 60 min.

[0033] The mixture was placed in a hydrothermal reactor and reacted at 150°C for 12h.

[0034] The resulting mixture was centrifuged at 4000 rpm for 10 min, and the supernatant of the upper 1 / 2 was collected. Then add 15ml of deionized water, continue to centrifuge at 4000rpm for 10min, and this process is repeated 5 times. The finally obtained dispersion is the fluorinated graphene dispersion of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com