Distance-variable arrangement method for marine riser vibration suppression devices

A layout method and variable spacing technology, applied in the direction of drill pipe, casing, earthwork drilling, etc., can solve the problems of large drag force load, easy fatigue damage, performance redundancy, etc., to reduce the drag force load and ensure the suppression effect , the effect of great practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

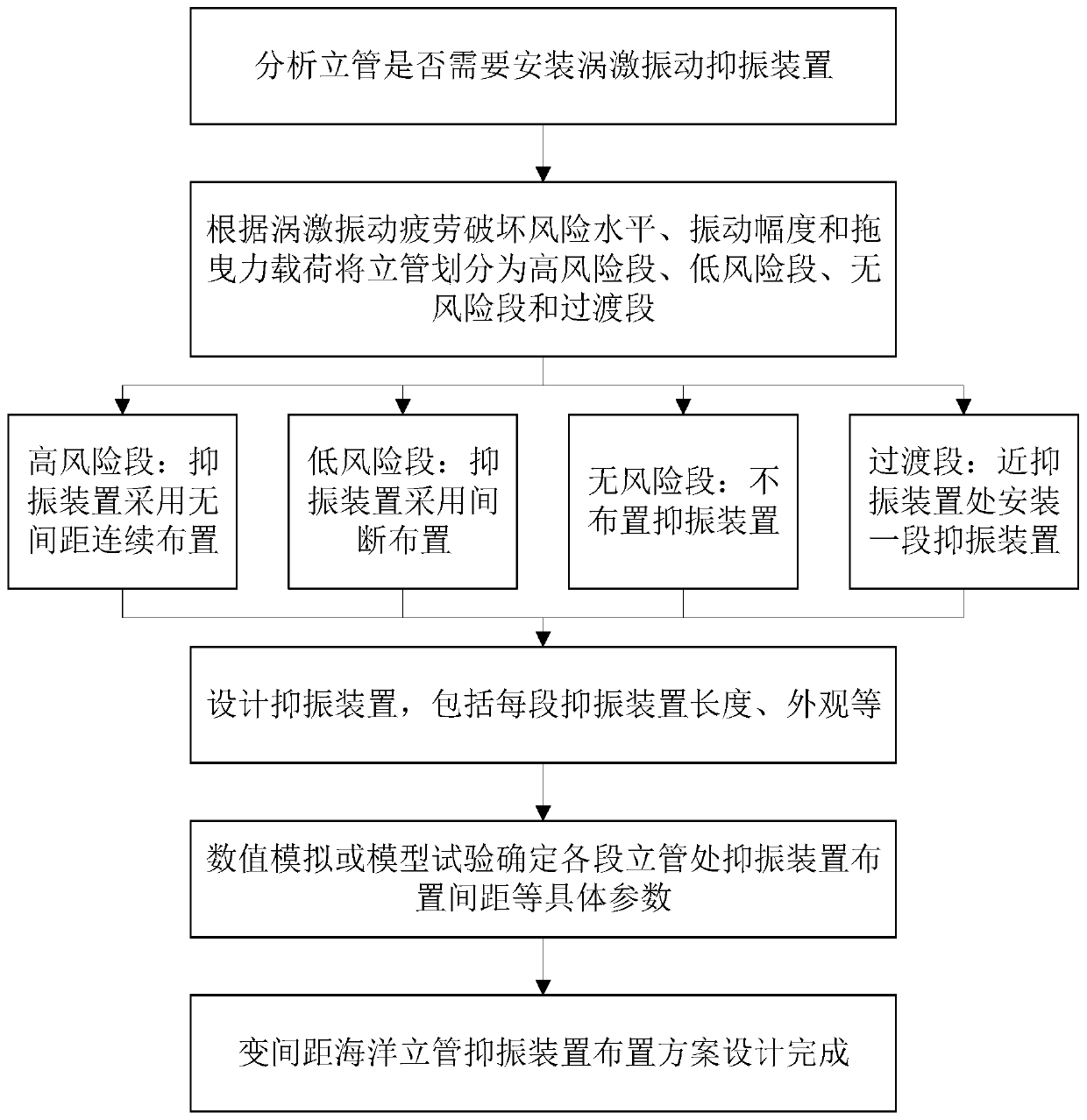

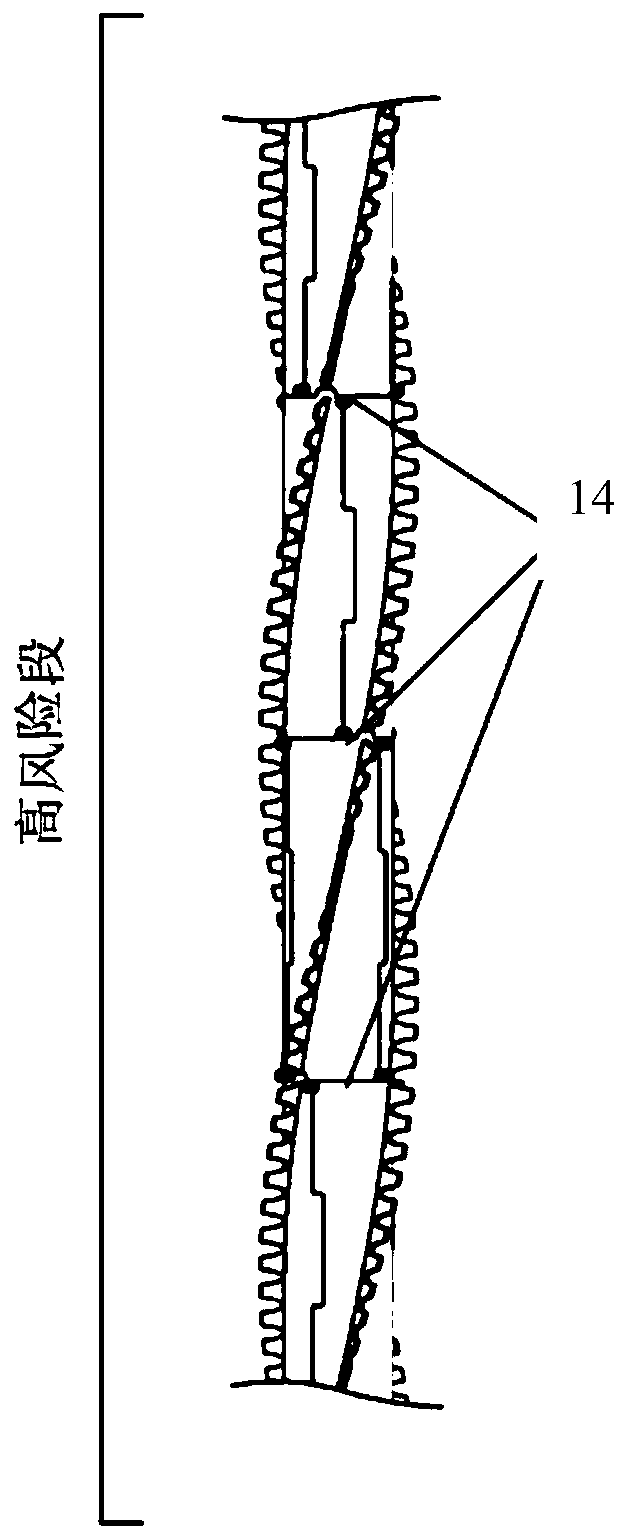

[0049] see figure 1 As shown in Fig. 8, the present invention provides a method for arranging vibration suppression devices of variable-pitch marine risers, which is suitable for vibration suppression devices distributed axially symmetrically after installation, which includes the following steps:

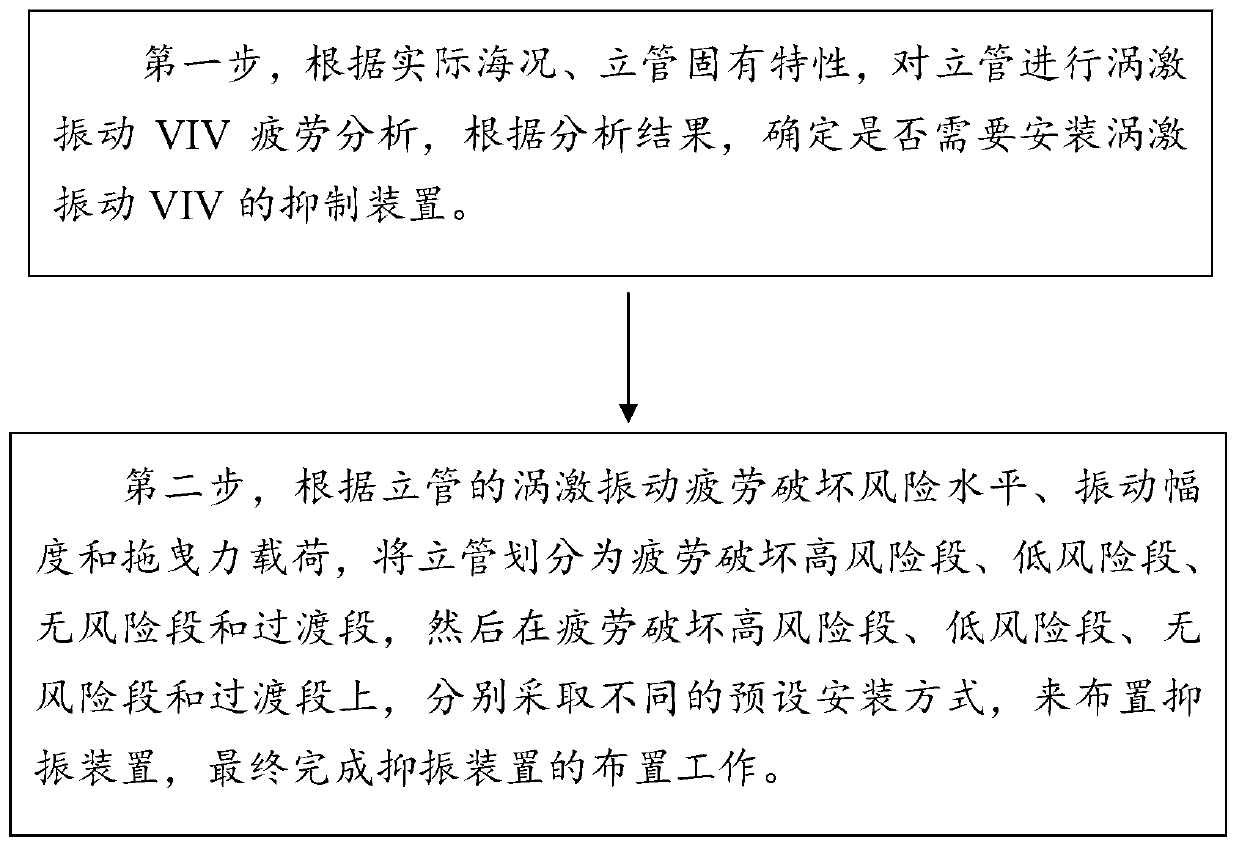

[0050] In the first step, according to the actual sea conditions (including but not limited to current velocity, direction, water depth, ocean current characteristics changing with water depth, sea area wave characteristics, etc.), the inherent characteristics of the riser (length-to-diameter ratio, damping, mass ratio, etc.), conduct Vortex-induced vibration (VIV) fatigue analysis, according to the analysis results, determine whether it is neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com