Device for monitoring real-time state of steel ladle lining

A real-time monitoring, ladle technology, applied in measuring devices, measuring heat, instruments, etc., can solve the problems of low detection accuracy of ladle lining temperature and damage degree, and achieve accurate monitoring of temperature and damage degree, accurate residual thickness value, and guarantee safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

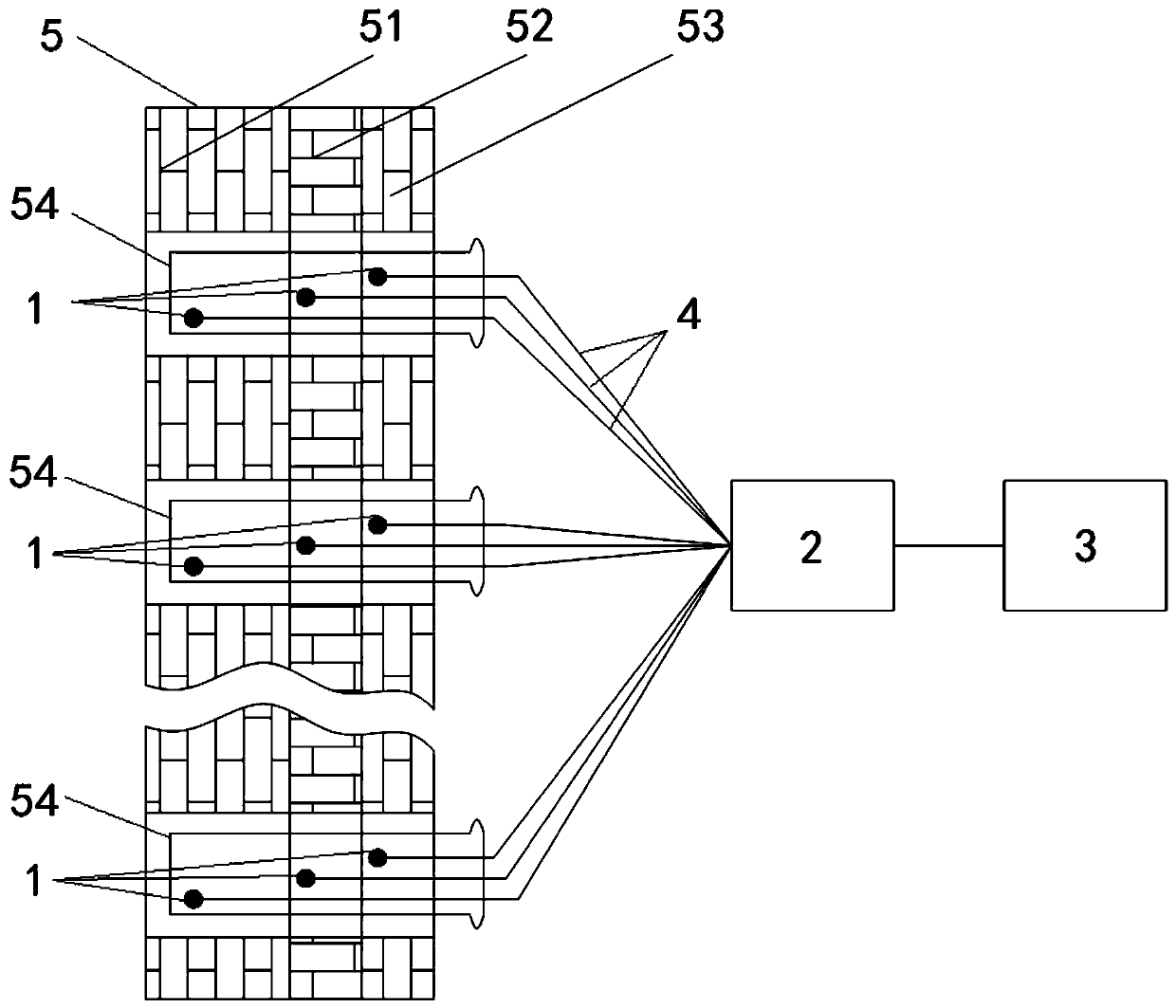

[0013] Such as figure 1 As shown, Embodiment 1 of the present invention provides a real-time monitoring device for the ladle lining state, including a plurality of optical fiber sensors 1, a signal demodulator 2 and a host computer 3;

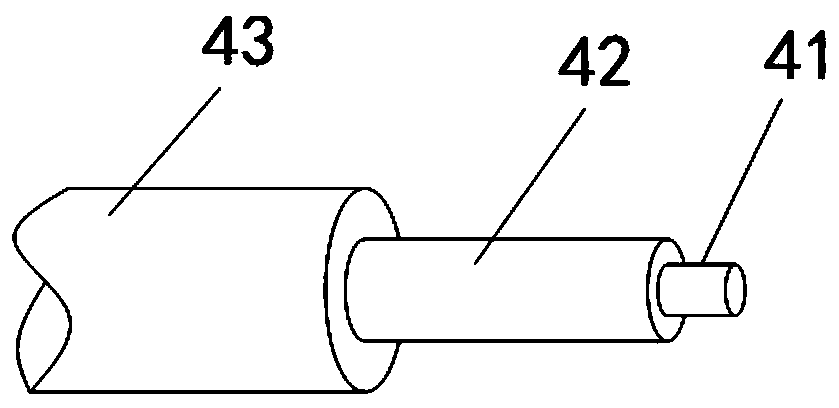

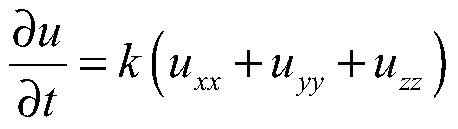

[0014] A plurality of air holes 54 are provided on the ladle liner 5, and each of the air holes 54 is respectively distributed at different positions on the ladle liner 5, and a plurality of the optical fiber sensors 1 are installed in each of the air holes 54, each A plurality of optical fiber sensors 1 in the air hole 54 are respectively connected to the signal demodulator 2 through a multimode optical fiber 4, and are used to obtain the temperature of different positions and depths of the ladle lining 5, so The host computer 3 is connected with the signal demodulator 2 and is used to calculate the residual thickness prediction value at different positions of the ladle lining 5 according to the temperature signals at different positions and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com