Data center bus structure

A busbar structure and data center technology, applied in the direction of fully enclosed busbar devices, etc., can solve the problems of low anti-corrosion level, low protection level, ugly appearance, etc., and achieve the effect of improving anti-corrosion level, improving stability, and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content of the present invention in detail, the present invention will be further described below in conjunction with the accompanying drawings.

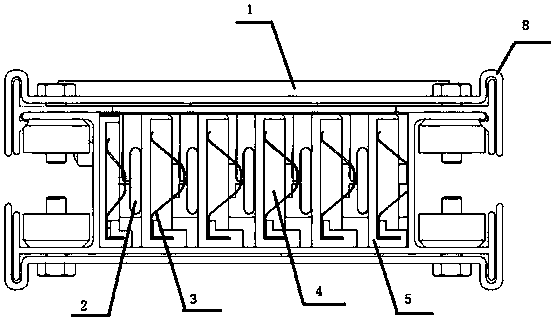

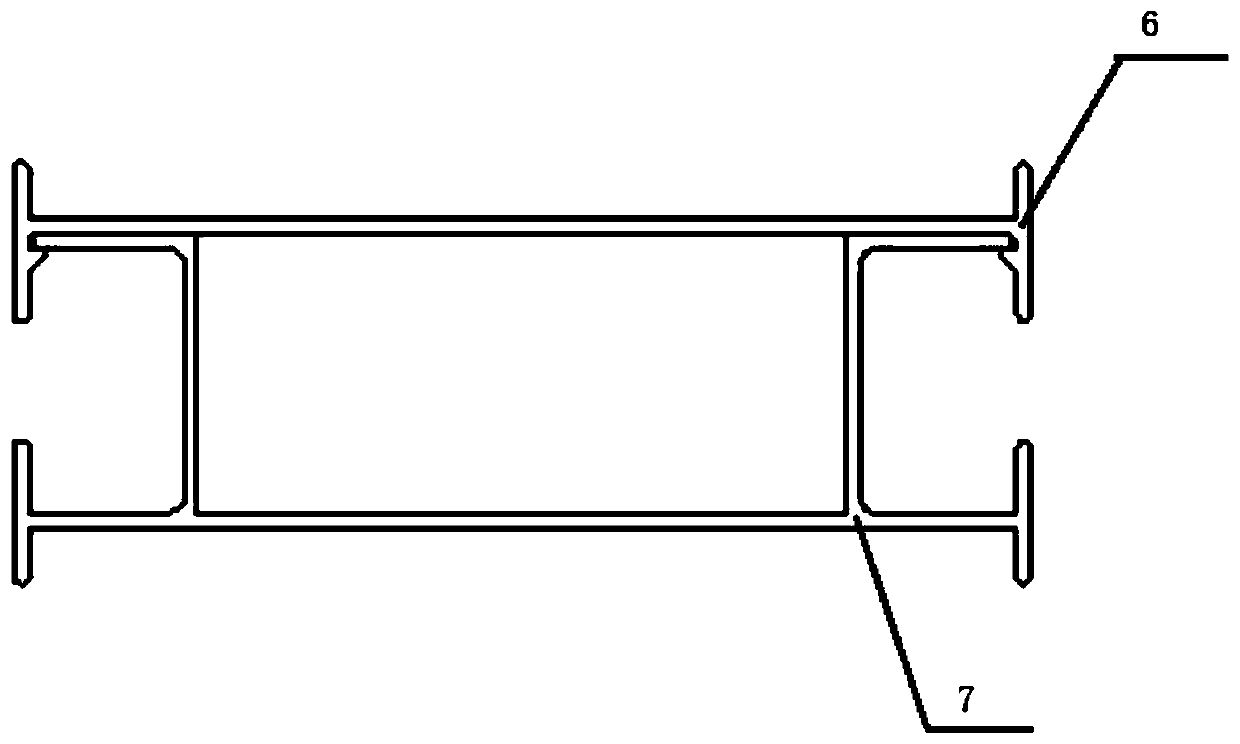

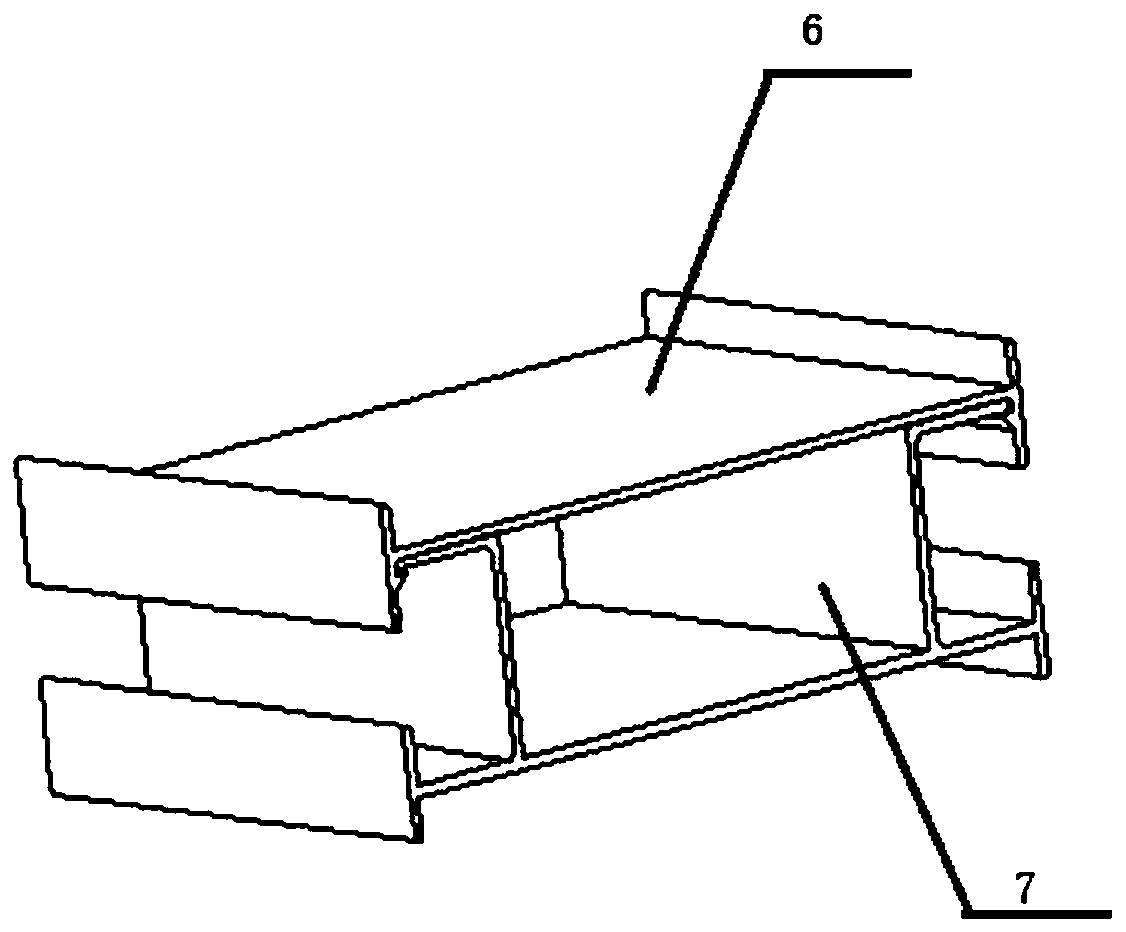

[0021] Such as figure 1 with Figure 4 As shown: the main part of a data center busbar connection structure of the present invention is a busbar tank body 1, the interior of the busbar tank body 1 is evenly divided into several tank bodies 4, and each tank body 4 is separated by an insulating partition plate 5, One end of the spring piece 3 is fixed on the insulating partition 5 , one side of the copper bar 2 abuts against the spring piece 3 , and the other side abuts against the insulating partition 5 . The spring leaf 3 presses the copper bar 2 tightly on the insulating partition 5 by its own pre-tightening force.

[0022] The copper bar 2 has a fixed end and a non-fixed end, the fixed end of the copper bar 2 abuts against the fixed end of the next section of the copper bar, and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com