Graphene-containing sealant for heavy-duty corrosion prevention and preparation method thereof

A graphene and sealant technology, which is applied in the field of graphene-containing heavy-duty anti-corrosion sealant and its preparation, can solve problems such as threats to flight safety, corrosion of structural equipment, and degradation of sealant sealing performance, so as to block and isolate corrosive media , good dispersion and uniform distribution, and the effect of improving heavy anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

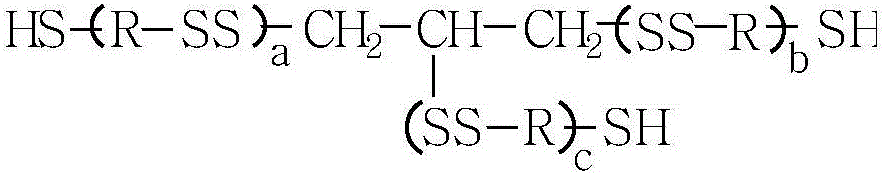

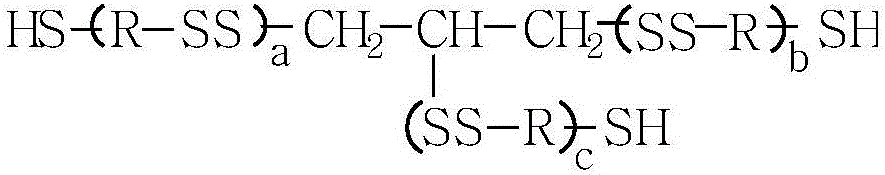

Method used

Image

Examples

Embodiment 1

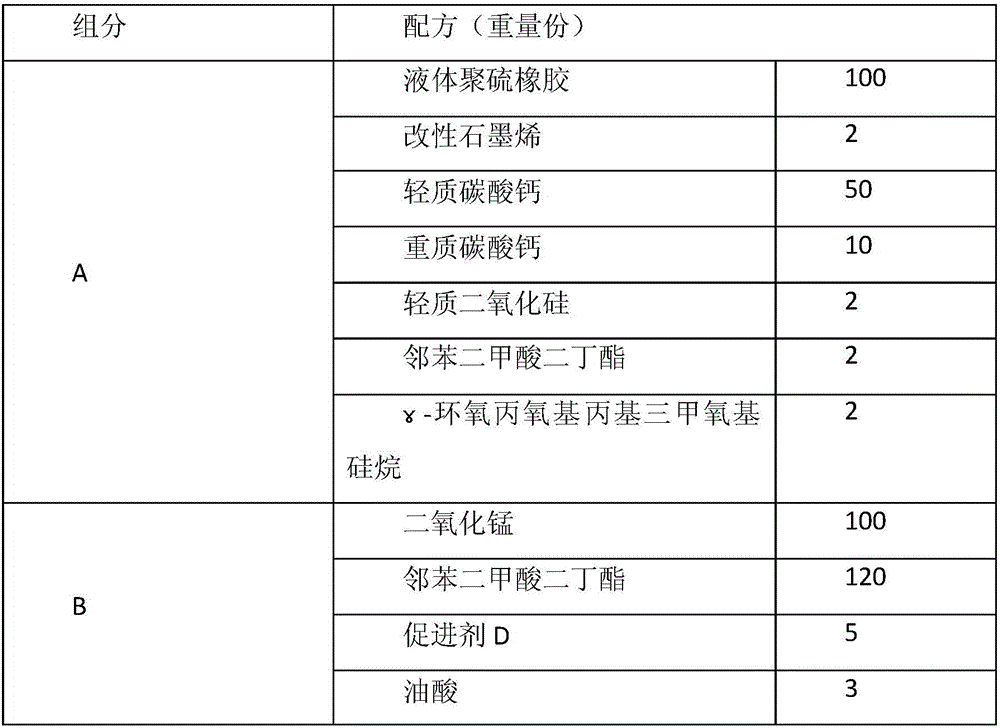

[0035] The composition formula of a kind of heavy anti-corrosion sealant containing graphene is as shown in table 1:

[0036] Table 1.1 Formula composition of heavy anti-corrosion sealant

[0037]

[0038] Among them, graphene is modified as follows: firstly, γ-glycidoxypropyltrimethoxysilane coupling agent and γ-mercaptopropyltriethoxysilane are mixed at a mass ratio of 1:1, and reacted at 70°C After 2 hours, a mixed-type silane coupling agent was obtained, and then 0.5 parts by weight of a mixed-type silane coupling agent was dissolved in 100 mL of 95% ethanol aqueous solution, mixed with 4 parts by weight of graphene oxide in the form of a spray, and mixed at 70 ° C. Stir for 2 hours, and finally dry the filtered solid in a blast oven at 120° C. for 24 hours to obtain a modified product.

[0039] After weighing the components in component A and roughly mixing them in proportion, use a three-roll mill to mix them three times until they are uniform; after roughly mixing c...

Embodiment 2

[0055] The composition formula of high temperature and fuel resistant fluorosilicone sealant is shown in Table 2:

[0056] Table 2.1 Formula composition of heavy anti-corrosion sealant

[0057]

[0058] The modification of graphene is as follows: First, mix γ-aminopropyltriethoxysilane and γ-mercaptopropyltriethoxysilane at a mass ratio of 1:1, and react at 70°C for 2 hours to obtain a mixed silane Coupling agent, then take 0.7 parts by weight of mixed silane coupling agent and dissolve it in 100mL of 95% ethanol aqueous solution, mix it with 5 parts by weight of graphene oxide in the form of spray and stir at 70°C for 4h, and finally filter The final solid was dried in a blast oven at 120° C. for 24 hours to obtain a modified product.

[0059] After weighing the components in component A and roughly mixing them in proportion, use a three-roll mill to mix them three times until they are uniform; after roughly mixing component B, use a three-roll mill to mix them three time...

Embodiment 3

[0075] The composition formula of the heavy anti-corrosion sealant is shown in Table 1:

[0076] Table 3.1 Formula composition of heavy anti-corrosion sealant

[0077]

[0078]

[0079] Among them, graphene is modified as follows: firstly, γ-glycidoxypropyltrimethoxysilane coupling agent and γ-aminopropyltriethoxysilane are mixed in a mass ratio of 1:1, and reacted at 70°C After 2 hours, the mixed silane coupling agent was obtained, and then 0.55 parts by weight of the mixed silane coupling agent was dissolved in 100 mL of 95% ethanol aqueous solution, and mixed with 4 parts by weight of graphene oxide in the form of spraying. Stir for 3 hours, and finally dry the filtered solid in a blast drying oven at 120° C. for 24 hours to obtain a modified product.

[0080] After weighing the components in component A and roughly mixing them in proportion, use a three-roll mill to mix them three times until they are uniform; after roughly mixing component B, use a three-roll mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com