Band-type brake control method of servo motor

A technology of servo motor and control method, applied in the direction of electric motor/converter plug, etc., can solve the problems of large energy consumption and large current, and achieve the effect of reducing the power consumption of the brake, maintaining a small current, and preventing the system from running out of control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

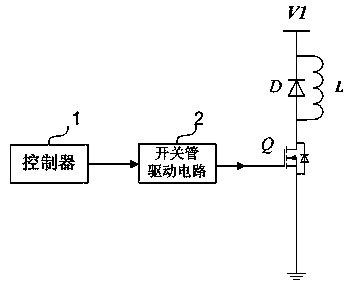

[0015] Please refer to figure 1 . A brake control method for a servo motor according to an embodiment of the present invention includes the following steps:

[0016] The controller 1 controls the switching tube Q to be turned on, so that the brake electromagnetic coil L is energized to work, wherein the switching tube Q is set on the path where the brake opening voltage V1 supplies power to the brake electromagnetic coil L;

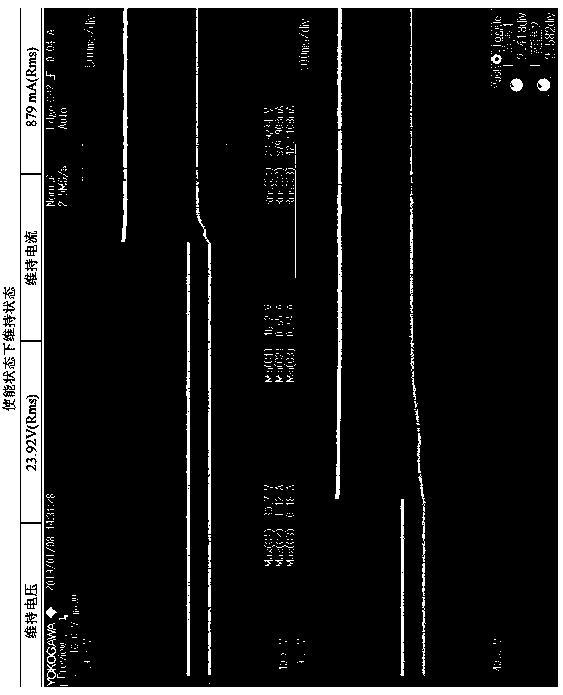

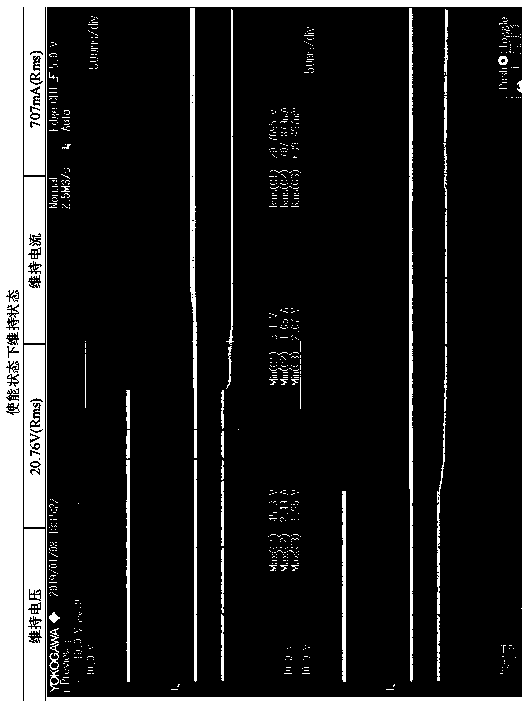

[0017] The controller 1 outputs a PWM signal to the switch tube Q after the preset time t1 has elapsed from the time when the switch tube Q is turned on, and adjusts the duty cycle of the PWM signal output to the switch tube Q, so that the brake electromagnetic coil L The operating voltage gradually decreases until it reaches a preset maintenance voltage, and the preset maintenance voltage is lower than the opening voltage of the brake.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com