Combined water pull system in breeding pond

A breeding pond and combined technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of severe top water stress, low efficiency, unreasonable design, etc., to reduce top water stress and avoid adsorption breeding Creatures, effects that reduce movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described in detail below in conjunction with the drawings and embodiments, but the present invention is not limited to the scope of the embodiments.

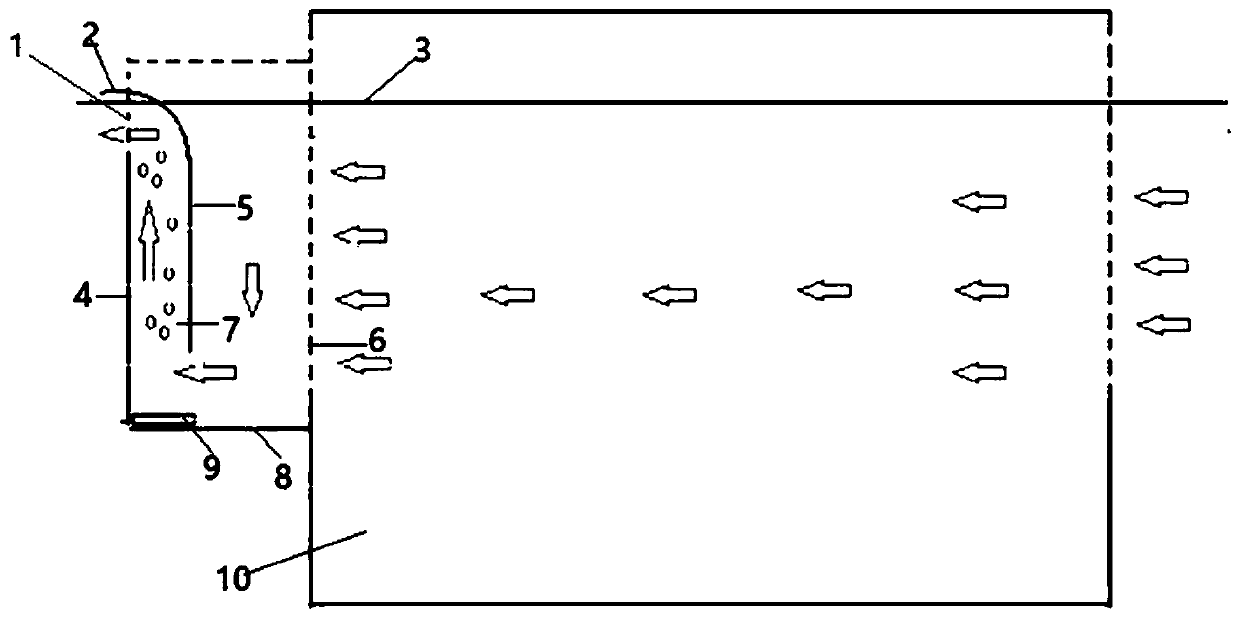

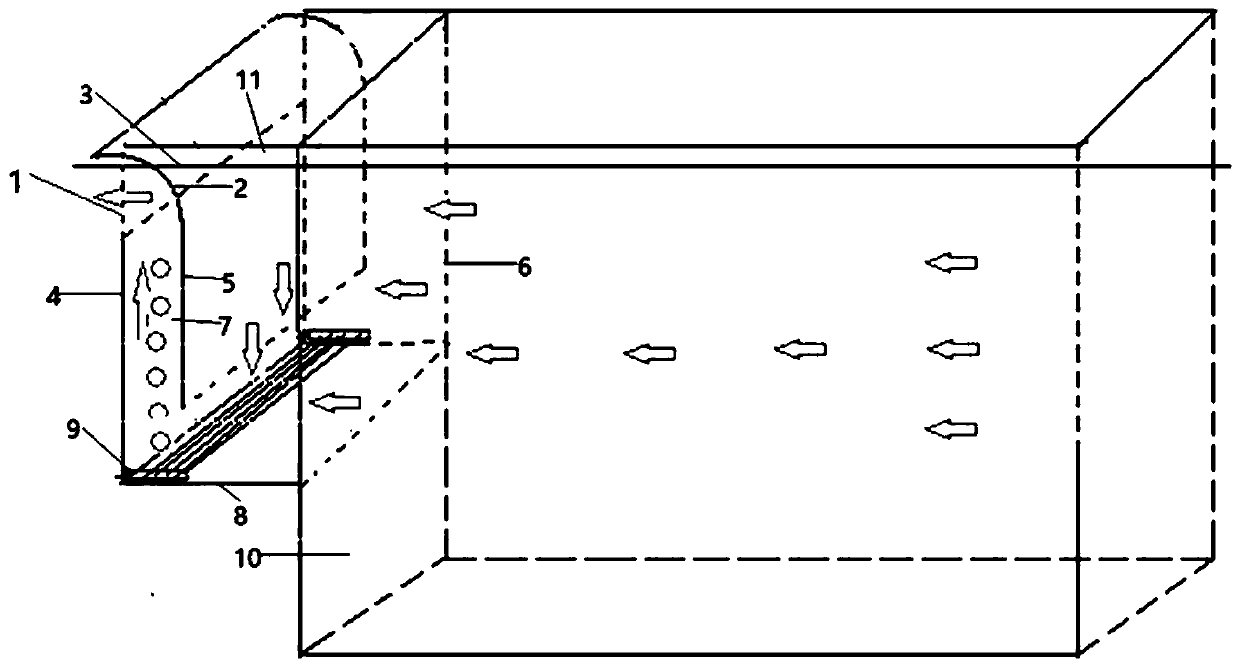

[0035] Such as Figure 1-Figure 2 As shown, this embodiment discloses a combined water pulling system for a culture pond, which includes a culture pond 10, and also includes a fishing net 1, a bottom baffle 8, a front baffle 4, an aeration assembly 9, a rear baffle 5 and side Baffle 11;

[0036] The upper edge of the side baffle 11 is higher than the horizontal plane 3, the lower edge is connected with the bottom baffle 8, the front edge is connected with the front baffle 4, the rear edge is connected with the wall of the culture pond 10, the middle is connected with the inclined baffle 2, the rear The baffle 5 is connected;

[0037] The bottom baffle 8, the rear baffle 5, the side baffle 11, the inclined baffle 2 and the fishing net 1 constitute a chamber 1, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com