Ore pulp defoaming device

A defoaming device and slurry technology, which is applied to the defoaming of flotation pulp mineralization foam products, most of the defoaming fields, can solve the problems of unstable product indicators, large water consumption, easy to block, etc., achieve good environmental protection effect, easy Easy to operate and adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

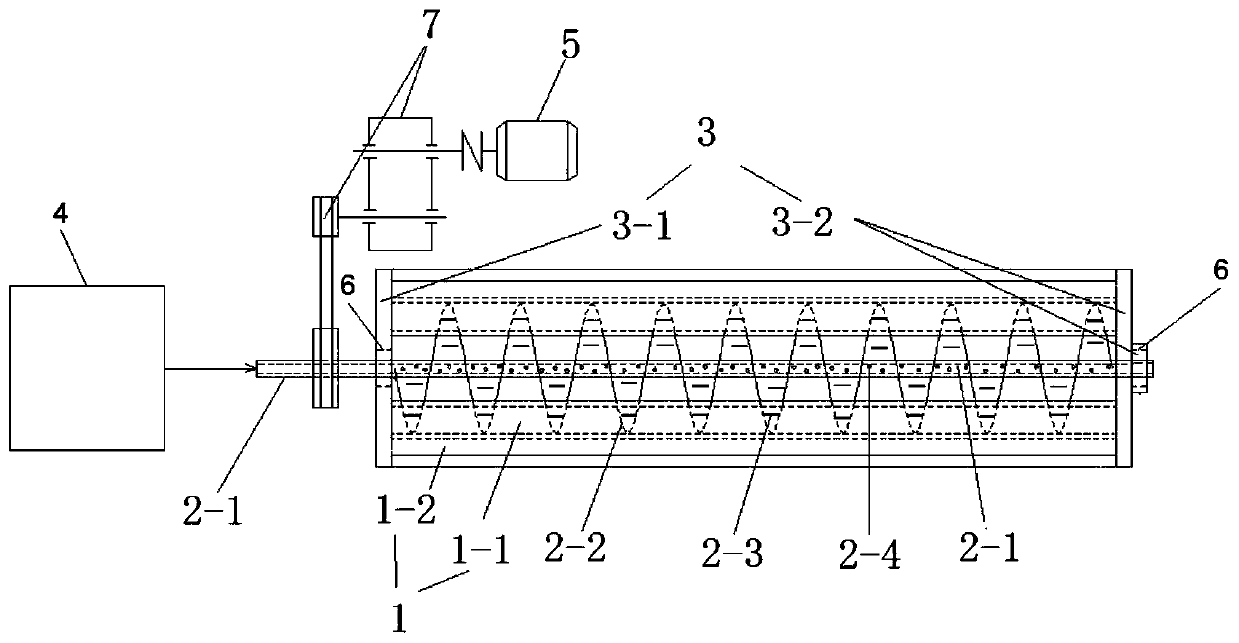

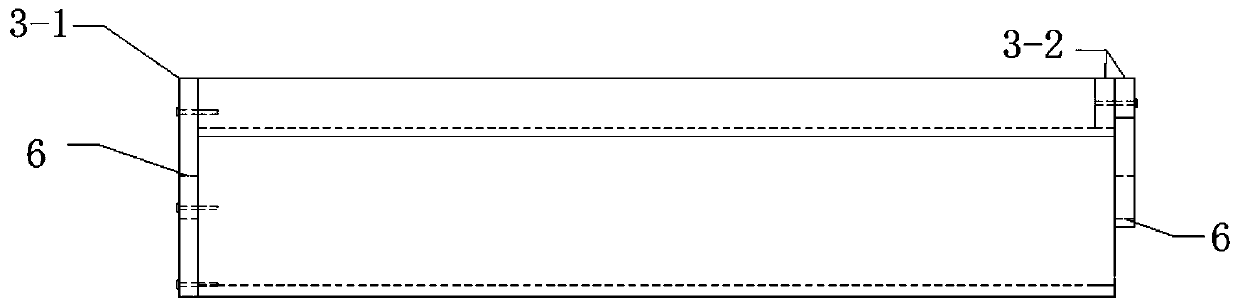

[0027] Embodiment of the present invention: a pulp defoaming device, including a foam tank device 1, a screw device 2, a fixing device 3, an air-water mixing device 4, a motor 5 and a speed change mechanism 7;

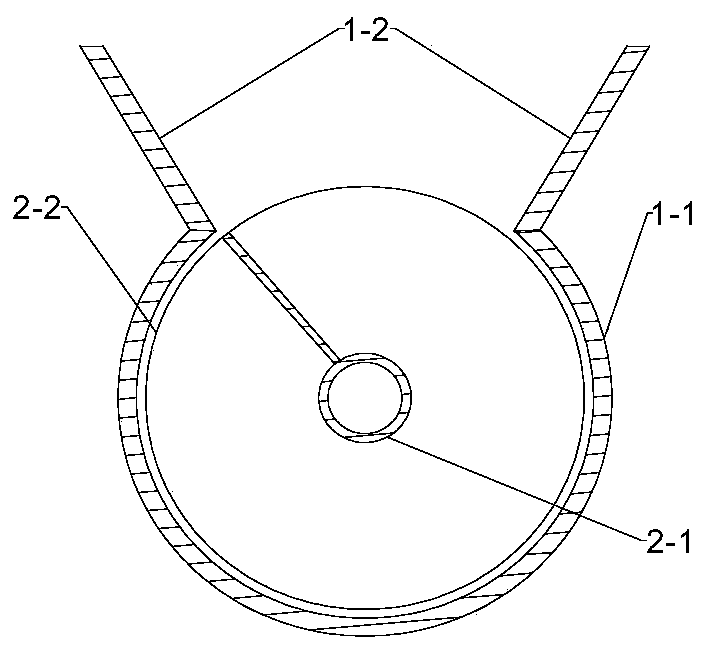

[0028] The composition of the foam tank device 1 includes a circular groove 1-1 and two inclined baffles 1-2, the circular groove 1-1 has a 3 / 4 opening, and the angle between the two inclined baffles 1-2 Not greater than 120°;

[0029] The spiral device 2 is composed of a central shaft 2-1, a spiral blade 2-2 stage defoaming brush 2-3, the central shaft 2-1 is a hollow shaft, and the central shaft 2-1 is provided with a spiral blade 2- 2. The defoaming brush 2-3 is installed on the spiral blade 2-2; a hole 2-4 communicating with the internal cavity is opened on the central axis 2-1, and the hole 2-4 is located between the intervals of the spiral blade 2-2 between;

[0030] The main body of the screw device 2 is in the foam tank device 1, the central axis 2-1 of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com