PCB washing device and PCB washing cylinder overflow device thereof

A technology of a PCB board and an overflow device, which is applied in the field of PCB board manufacturing, can solve the problems of inability to evaluate whether the board is clean or not, and achieves the effect of simple structure, reasonable design and water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

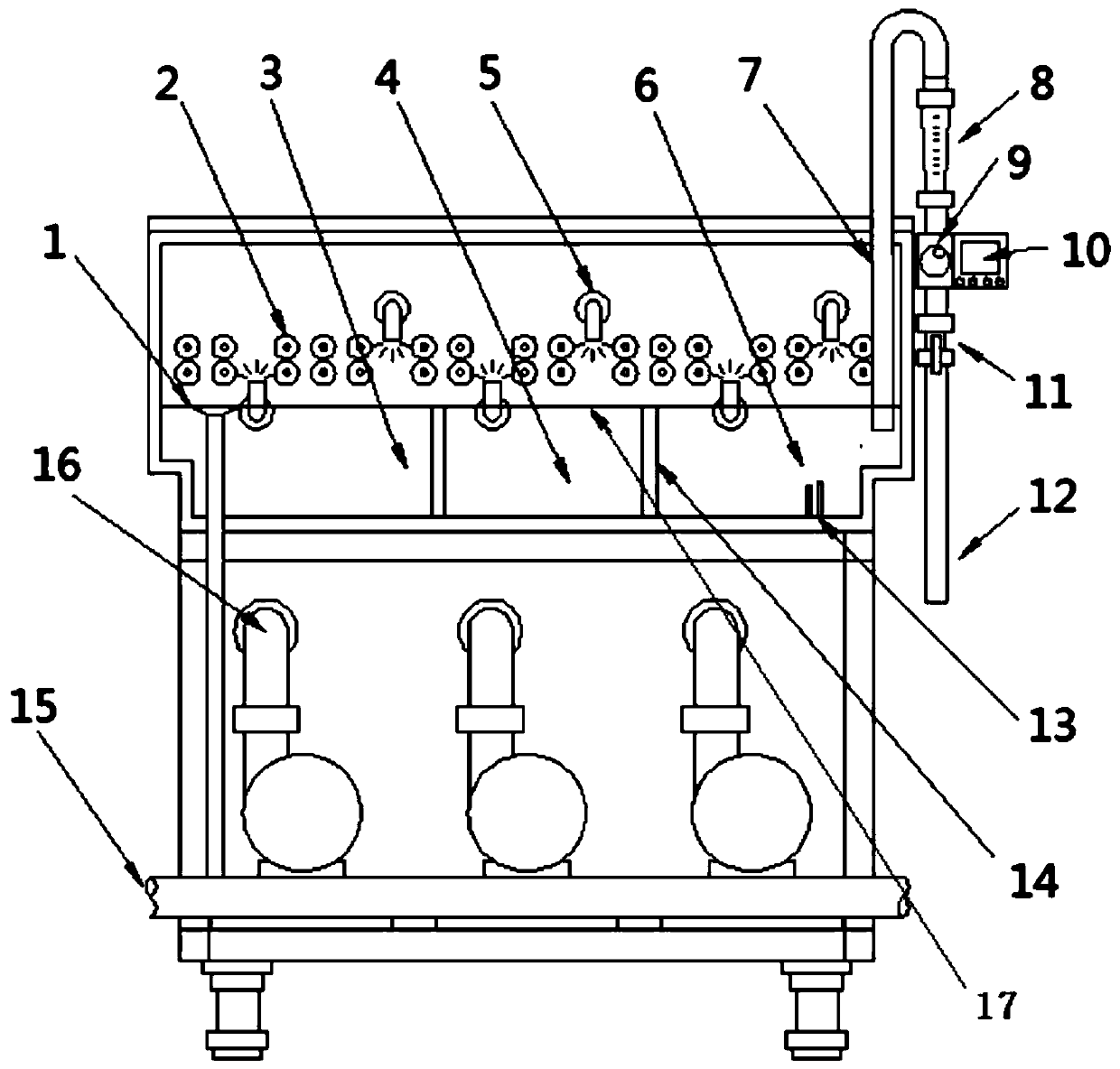

[0018] Referring to the drawings, the PCB board washing tank overflow device of the present invention includes a water inlet 7, an overflow outlet 1, and a water inlet system. The water inlet 7 is connected to the water inlet system through a pipe, and the overflow 1 is connected to an external sewage pipe 15 through a pipe; The overflow 1 is set inside the washing tank and the position is lower than the position of all washing nozzles 5, and the water inlet 7 is set inside the washing tank and the position is lower than the overflow 1; it also includes a water quality monitoring device, which includes water quality The monitoring sensor 13, the solenoid valve 9 and the online setting interface 10; the solenoid valve 9 is set on the connecting pipe between the water inlet 7 and the water inlet system, and the water quality monitoring device controls the water inlet 7 of the overflow device through the water quality monitoring sensor 13 Start and stop.

[0019] Preferably, in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com