A method for monitoring the cleanliness of electron microscope vacuum cavity

A technology of electron microscope and vacuum cavity, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as defects, and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

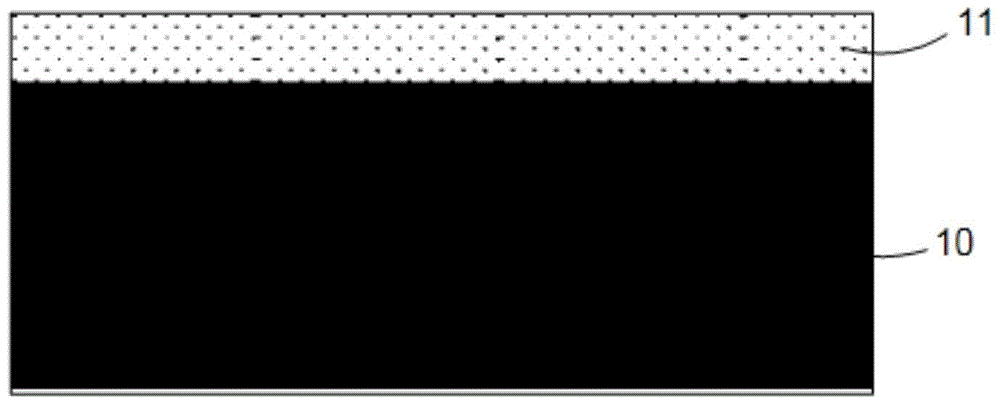

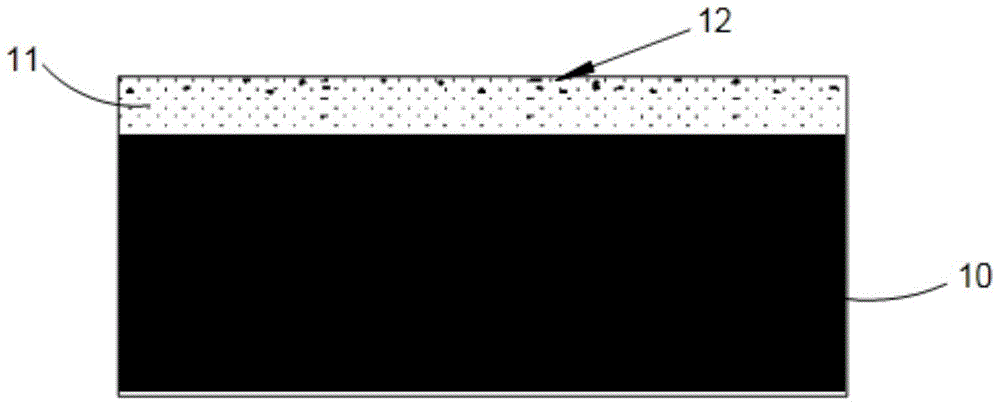

[0033] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

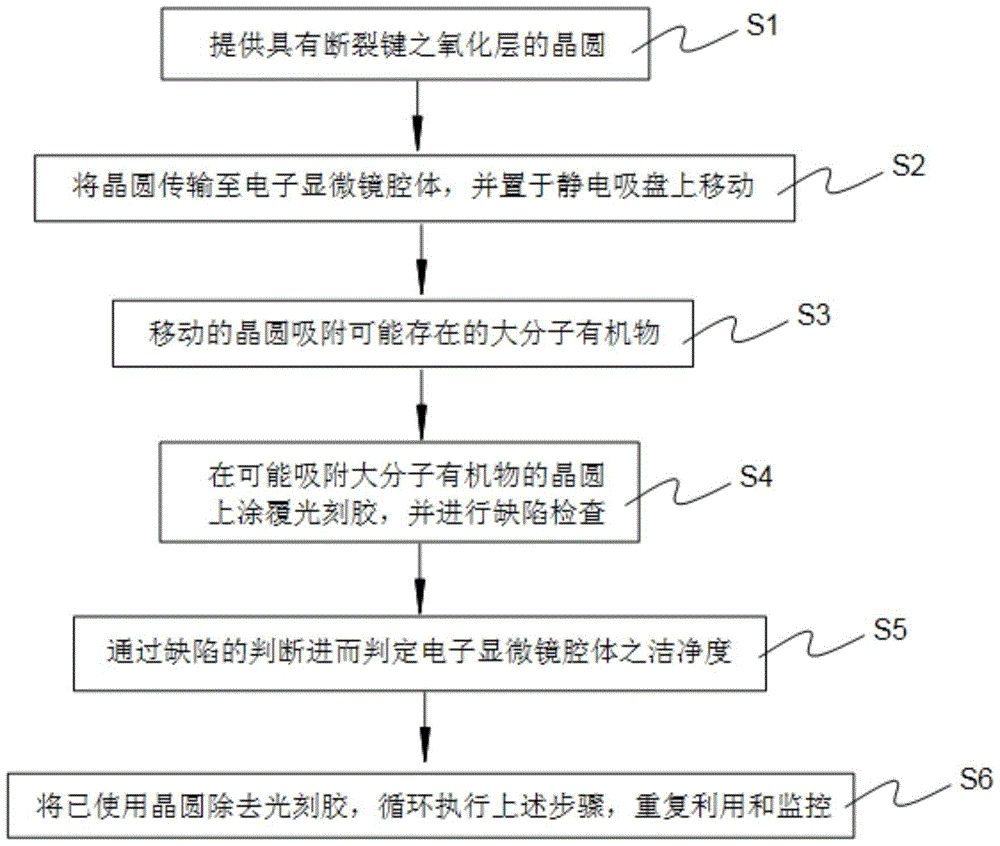

[0034] see figure 1 , figure 1 Shown is a flow chart of the method for monitoring the cleanliness of the electron microscope vacuum chamber of the present invention. The method for monitoring the cleanliness of the electron microscope vacuum cavity includes:

[0035] Executing step S1: providing a wafer with an oxide layer with broken bonds;

[0036] Executing step S2: transferring the wafer with the oxide layer of the broken bond into the vacuum chamber of the electron microscope, and placing it on the electrostatic chuck to move;

[0037] Executing step S3: the wafer with the oxide layer of broken bonds adsorbs macromolecular organic substances that may exist in the vacuum cavity of the electron microscope;

[0038] Executing step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com