Drilling machine support device structure and construction method thereof

A device structure and drilling rig technology, which is applied to portable drilling rigs, workbenches, manufacturing tools, etc., can solve the problems of non-vertical holes, inconvenient operation, hidden safety hazards, etc., to improve the quality of holes, facilitate construction, and improve construction accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

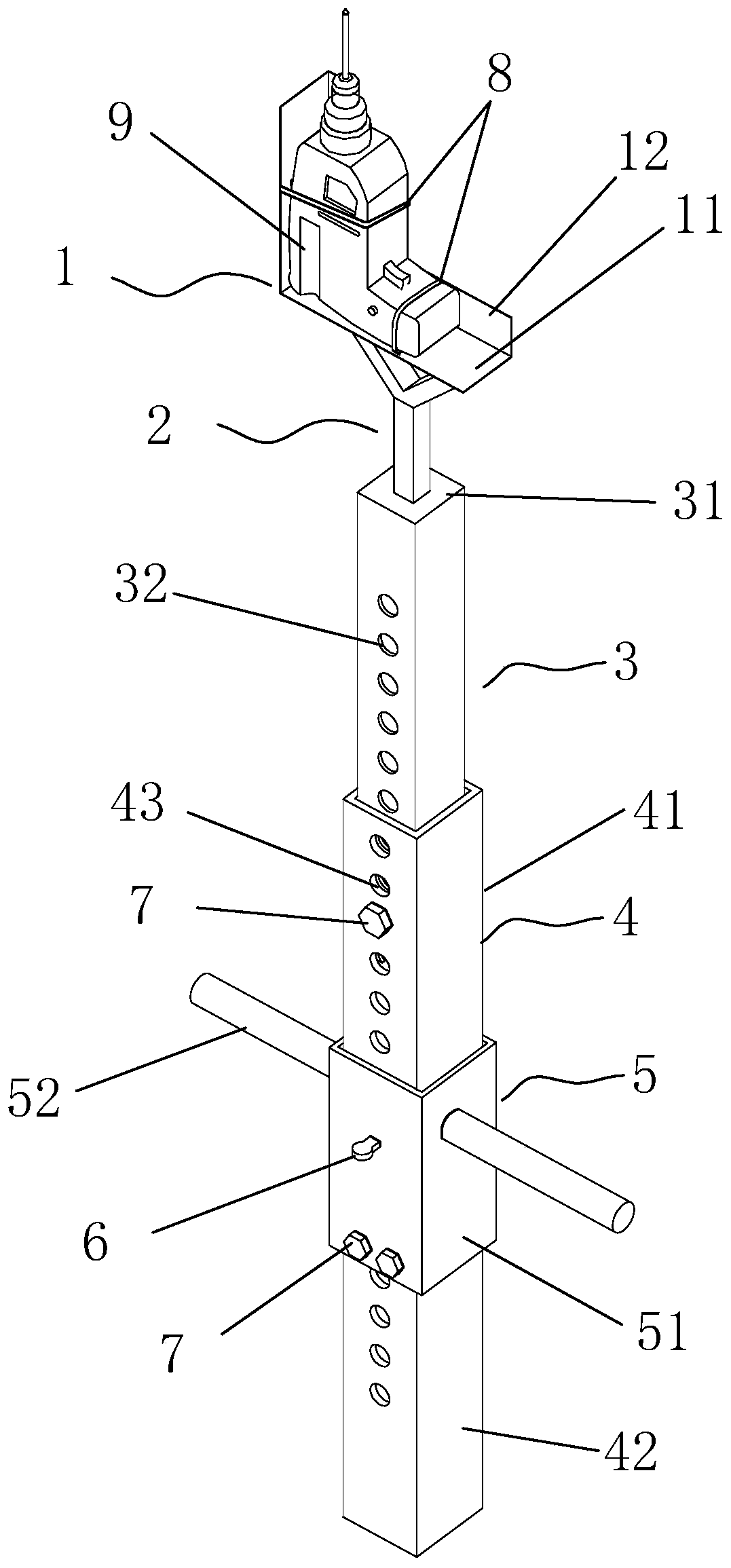

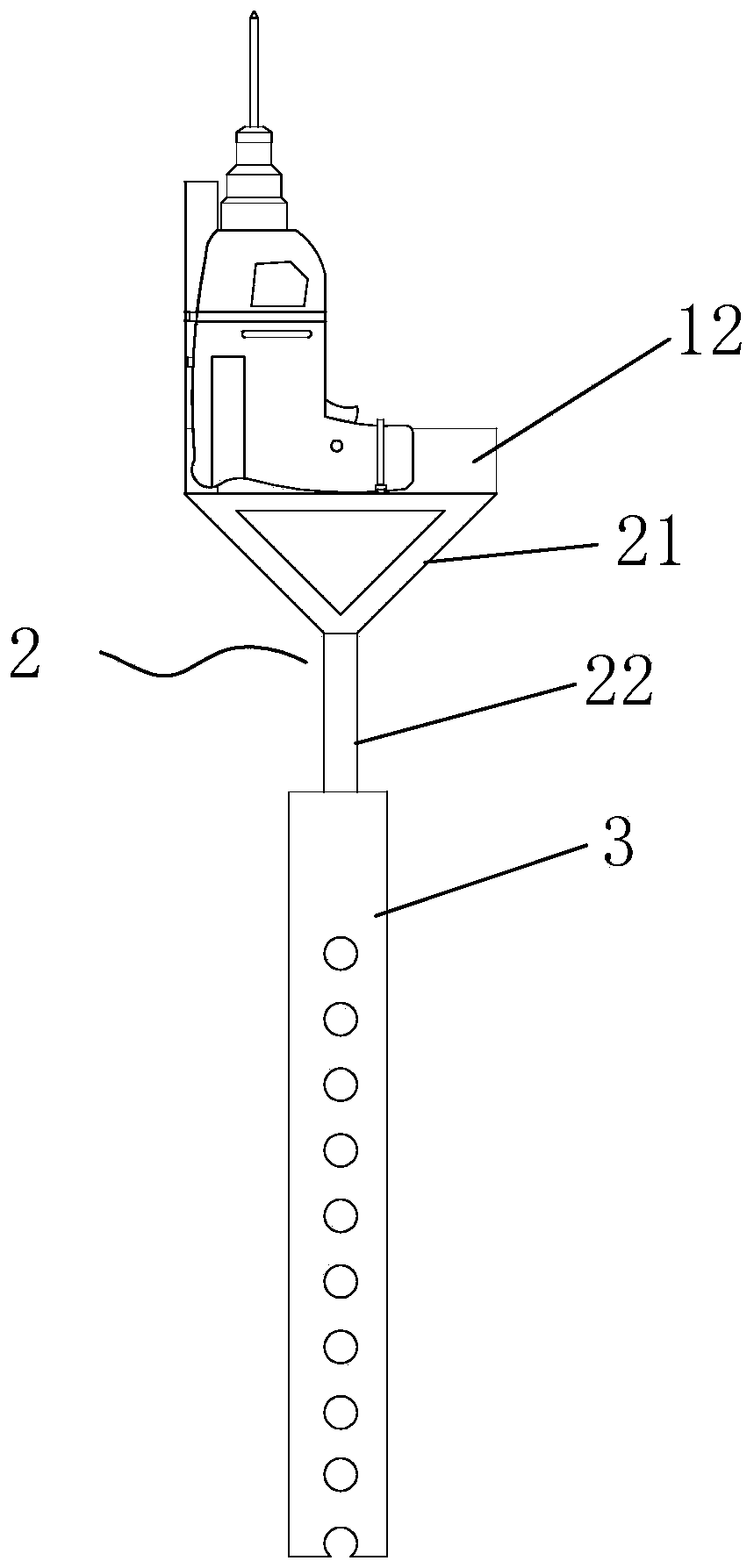

[0035] A kind of drilling rig support device structure, see figure 1 , including a fixed bracket and an adjustment device; the fixed bracket includes a fixed support 1 for installing a hand electric drill and a "Y" type fixed bracket 2; the fixed support includes a horizontally arranged L-shaped panel 11, and the L-shaped An L-shaped side of the panel is provided with an L-shaped side plate 12; the upper part 21 of the "Y"-shaped fixture is fixedly connected to the bottom of the L-shaped panel 11; the vertical plate and the L-shaped side of the L-shaped panel 11 The height of the vertical plate of the plate 12 does not exceed the installation position of the electric drill bit. The shape of the L-shaped panel 11 and the L-shaped side plate 12 is selected "L" type to facilitate the positioning of the electric drill and be fixed on the fixed support 1 to prevent the electric drill from shifting.

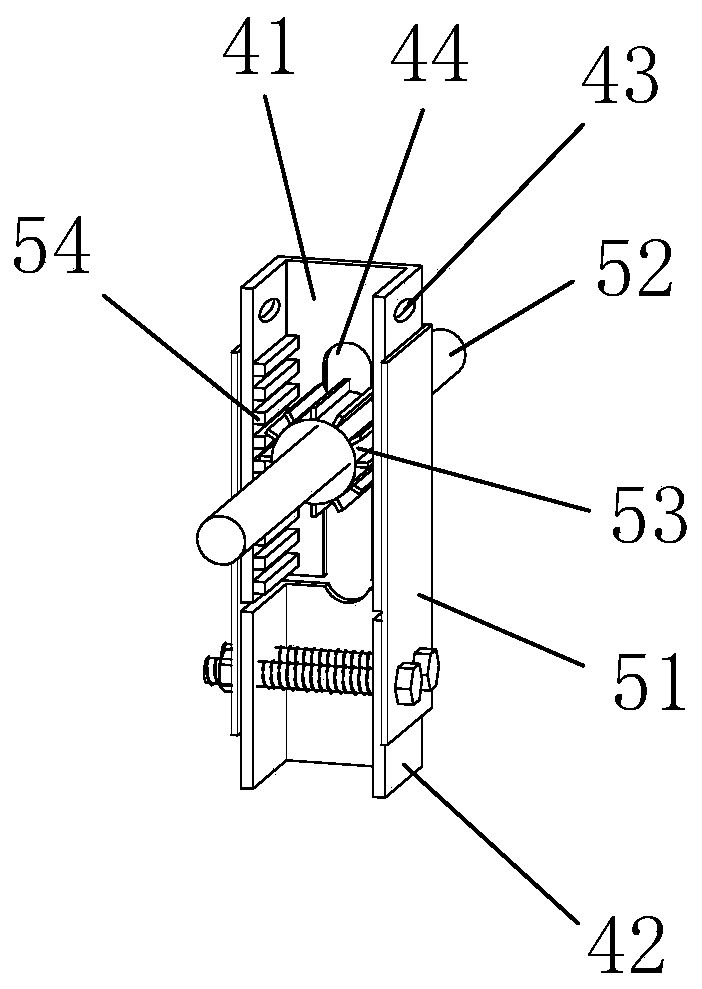

[0036] The adjustment device includes a coarse adjustment device and a fine adjus...

Embodiment 2

[0046] A construction method for a drilling rig support device structure, which is a construction method for a drilling rig support device structure described in Embodiment 1, and its construction process is as follows: A, determining the structural size of the drilling rig support device → B, making the drilling rig support device The components of the seat device structure → C, the structure of the assembled drilling rig support device → D, the rough adjustment of the structural height of the drilling rig support device → E, the fine adjustment of the structural height of the drilling rig support device → F, and precise drilling; specifically:

[0047] The step A, determining the structural size of the drilling rig support device includes the following main contents: determine the position of each positioning hole, and the diameter of the positioning hole is 10mm; select angle iron as the material of the fixed support 1; select square steel as " The material of Y " type fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com