Split armrest box of central channel

A central aisle, split-type technology, applied in the direction of closure, passenger space, packaging, etc., can solve the problems of high manufacturing precision, multiple components, mechanism linkage, etc., and achieve stable performance, concealed structure, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

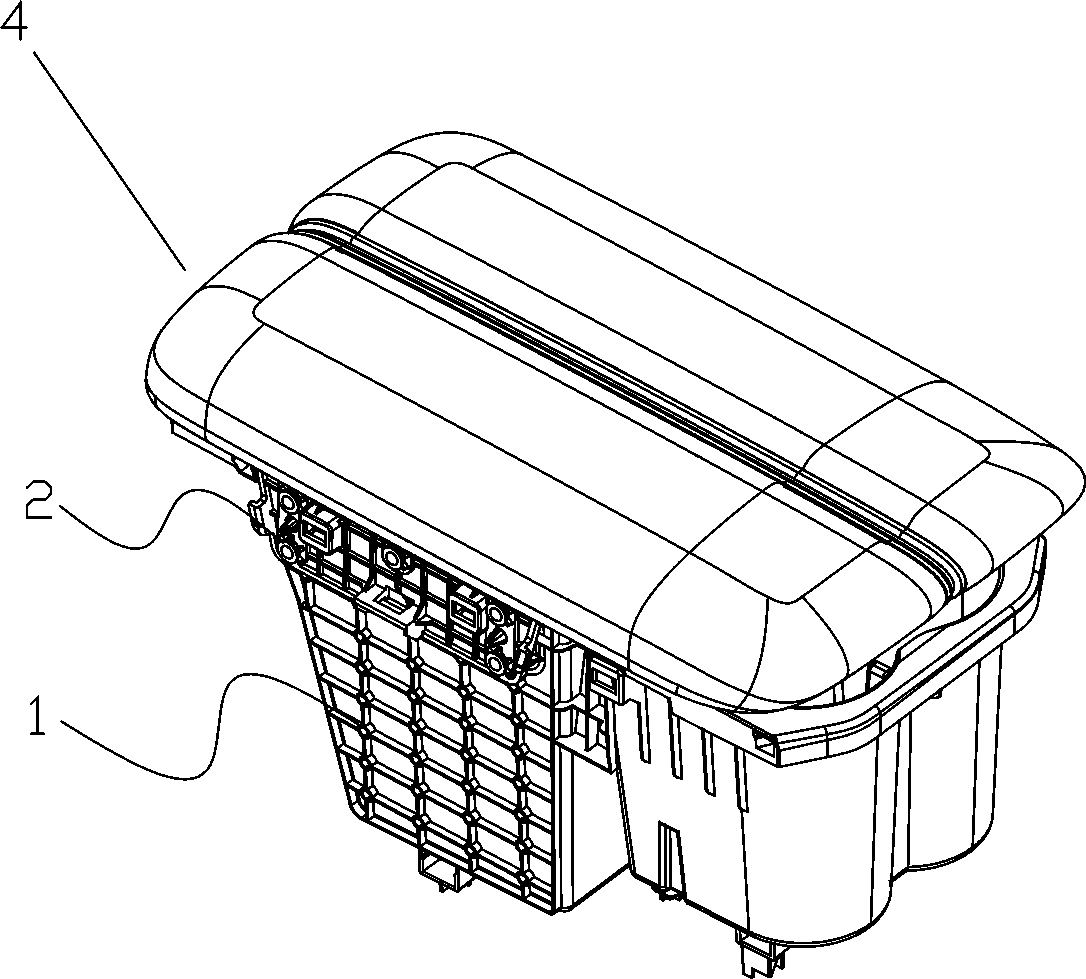

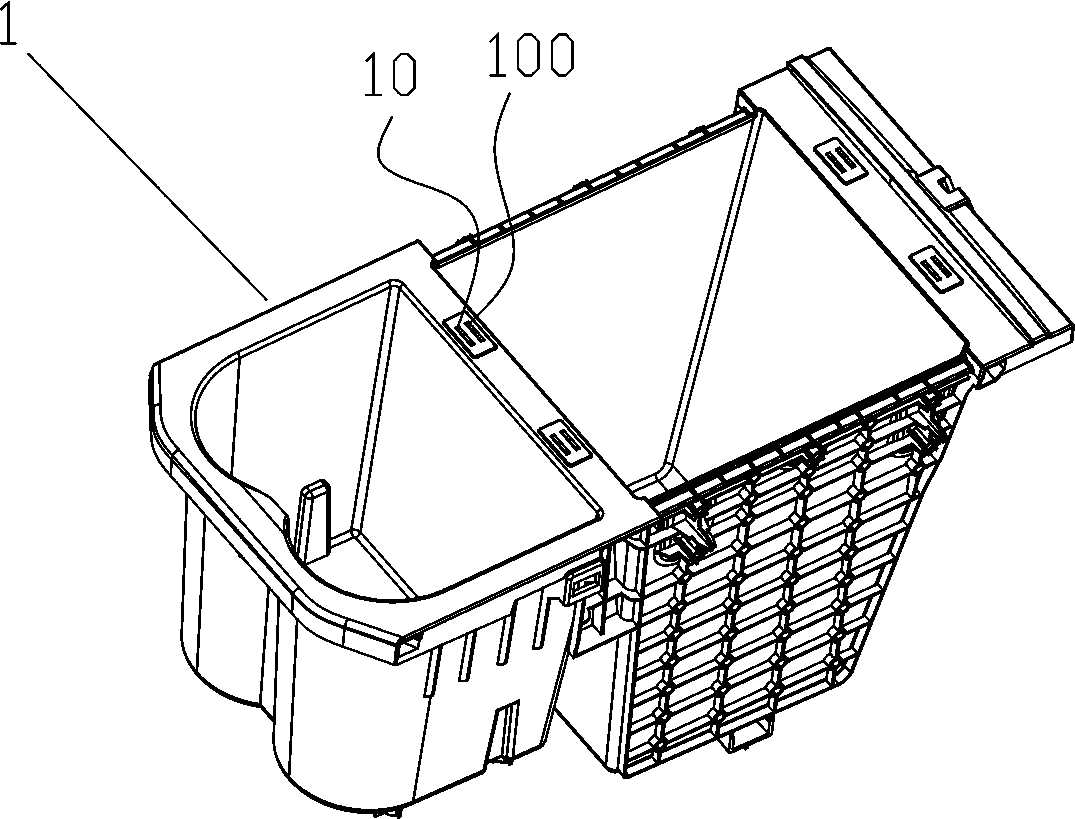

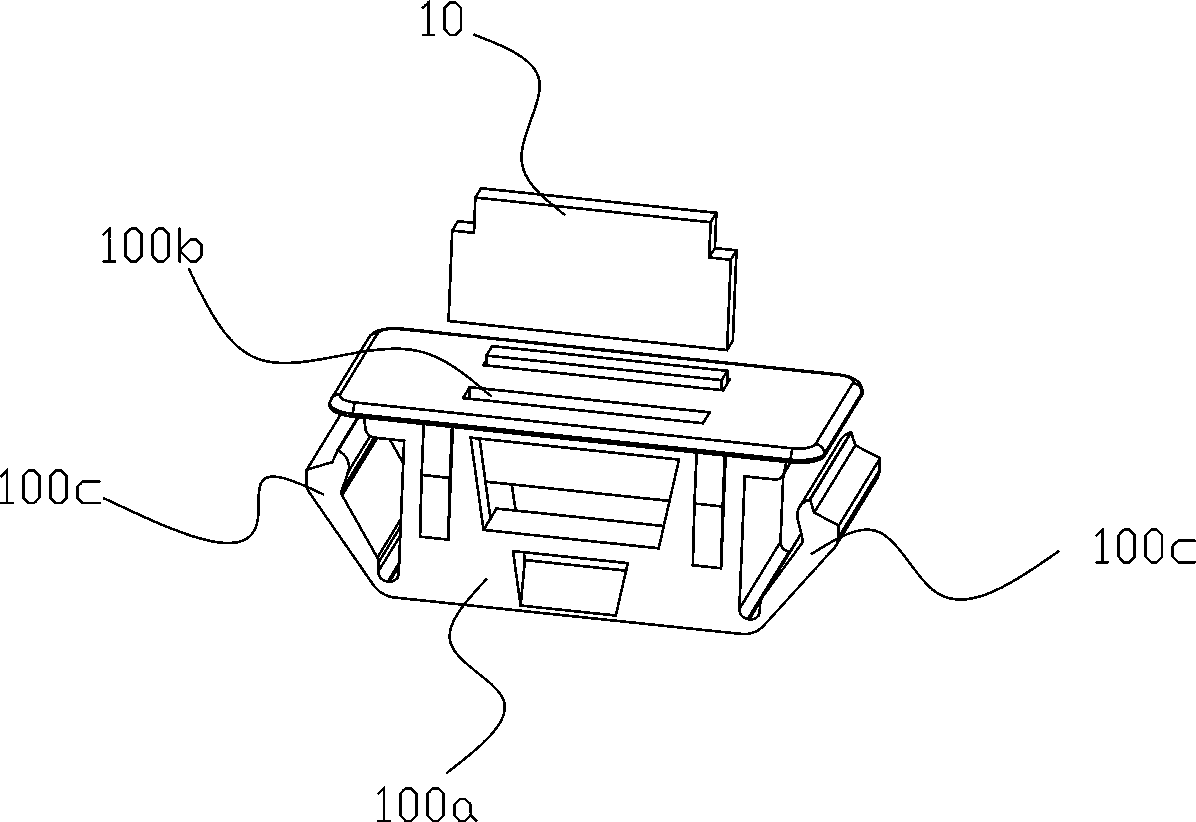

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 9 , the central passage split-type armrest box, including a box body 1 with an opening, an armrest cover hinge bracket 2 is arranged on both sides of the box body 1, and a cover plate mechanism 4 is arranged on each of the armrest cover hinge brackets 2 for rotation Two groups of torsion spring seats 20 are arranged at intervals on the upper end of the armrest cover hinge bracket 2, a torsion spring cover 30 is arranged inside the torsion spring seat, and a torsion spring 3 is arranged outside the torsion spring cover 30 , also includes a rotating shaft 31, the rotating shaft 31 passes through the two torsion spring sleeves 30, and is fixed with the torsion spring sleeves 30.

[0022] The cover mechanism 4 includes a cover seat 40 and a cover body 41 slidingly fitted with the cover seat 40. Specifically, two first slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com