Vane type oil pump and application thereof in engine lubrication system

An oil pump and vane-type technology, applied in the field of automotive engine pre-lubrication, can solve problems that are difficult to solve at the same time, pre-lubrication relies on electric power for secondary start, etc., and achieve the effects of improving life, saving cost and space, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0043] The specific implementation of the present invention will be described in detail below in conjunction with specific embodiments.

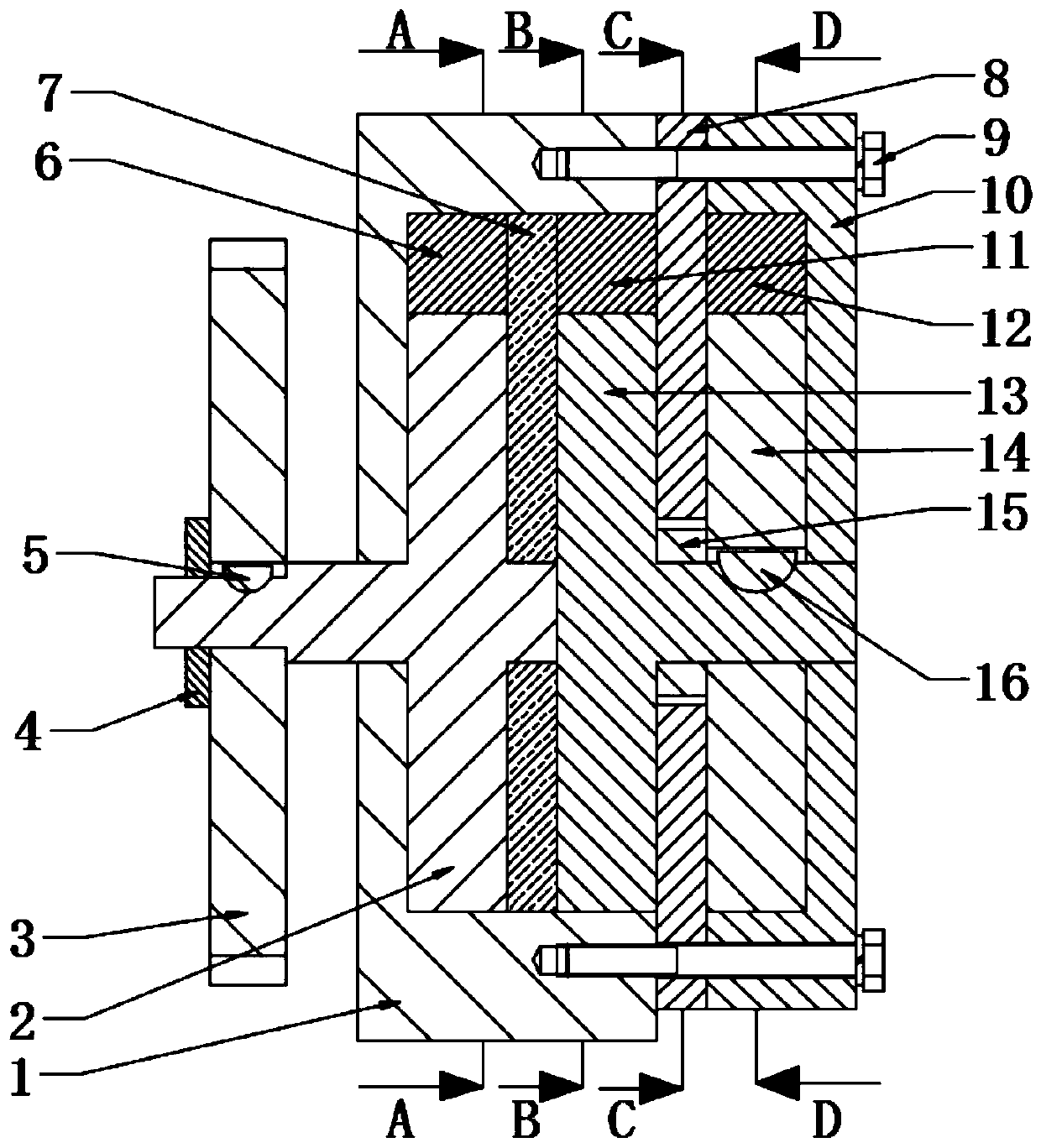

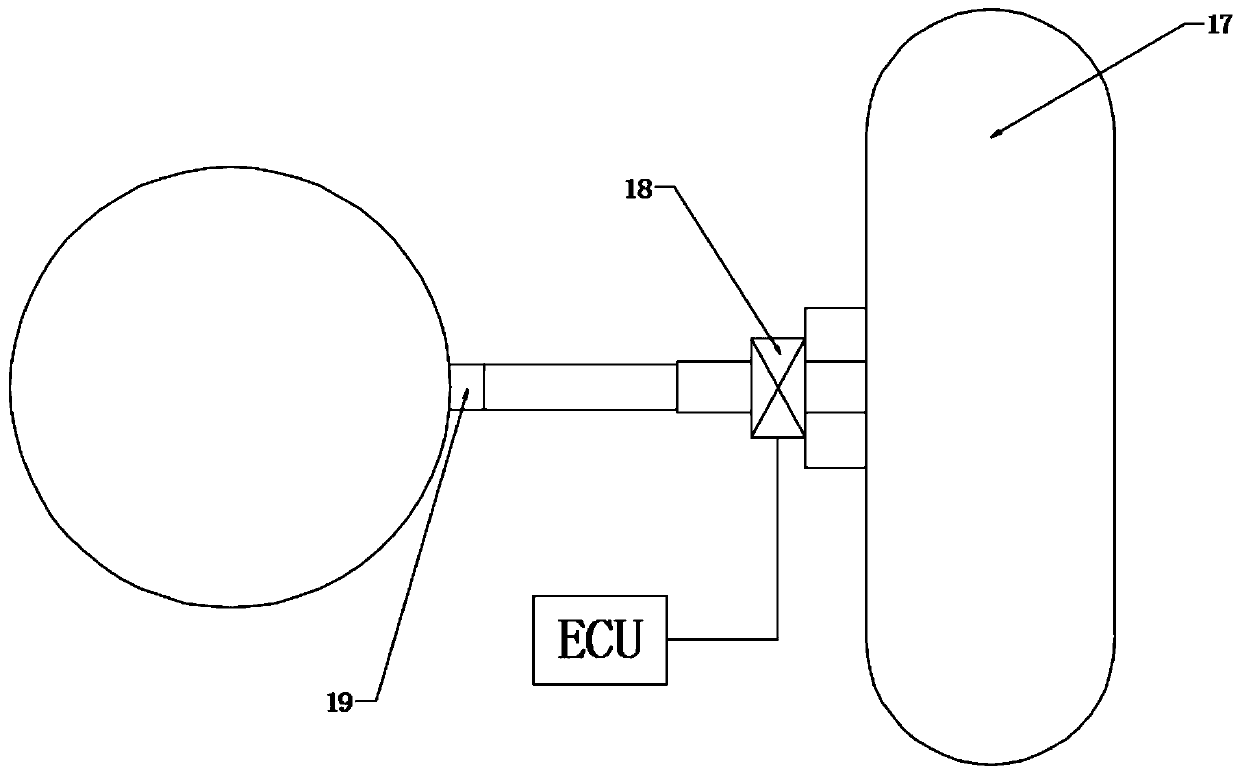

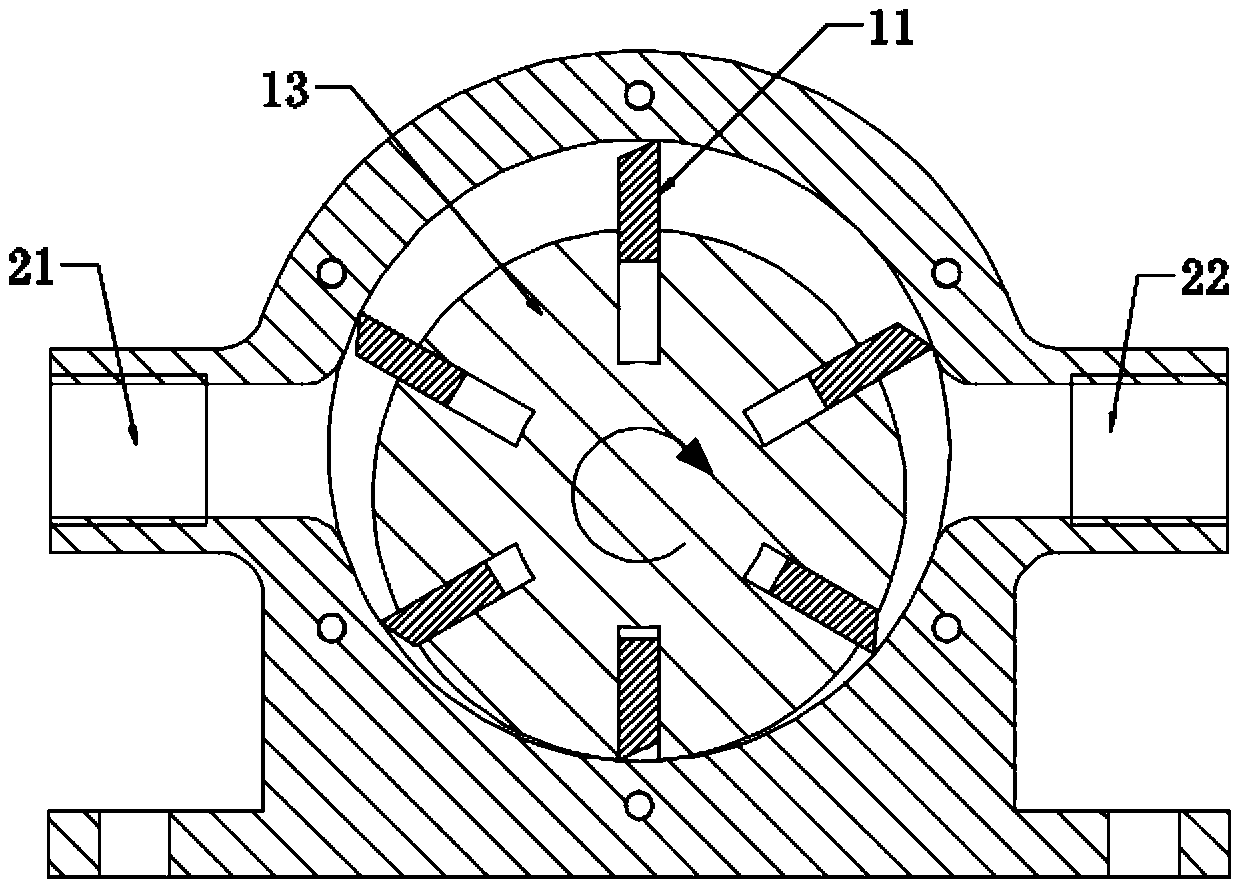

[0044] Such as figure 1 As shown, a vane type oil pump provided in an embodiment of the present invention includes:

[0045] The oil pump mechanism is used to introduce oil through the blade rotation and pump it out under pressure;

[0046] Pneumatic mechanism, connected to the transmission on one side of the oil pump mechanism, is used to drive and drive the oil pump mechanism to run synchronously through pneumatic means;

[0047] The driving mechanism is con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap