Compressor lubricating oil backflow structure and compressor

A lubricating oil and compressor technology, applied in the field of compressors, can solve the problems of reducing system energy efficiency, disturbance, excessive lubricating oil volume, etc., to achieve the effect of ensuring energy efficiency and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

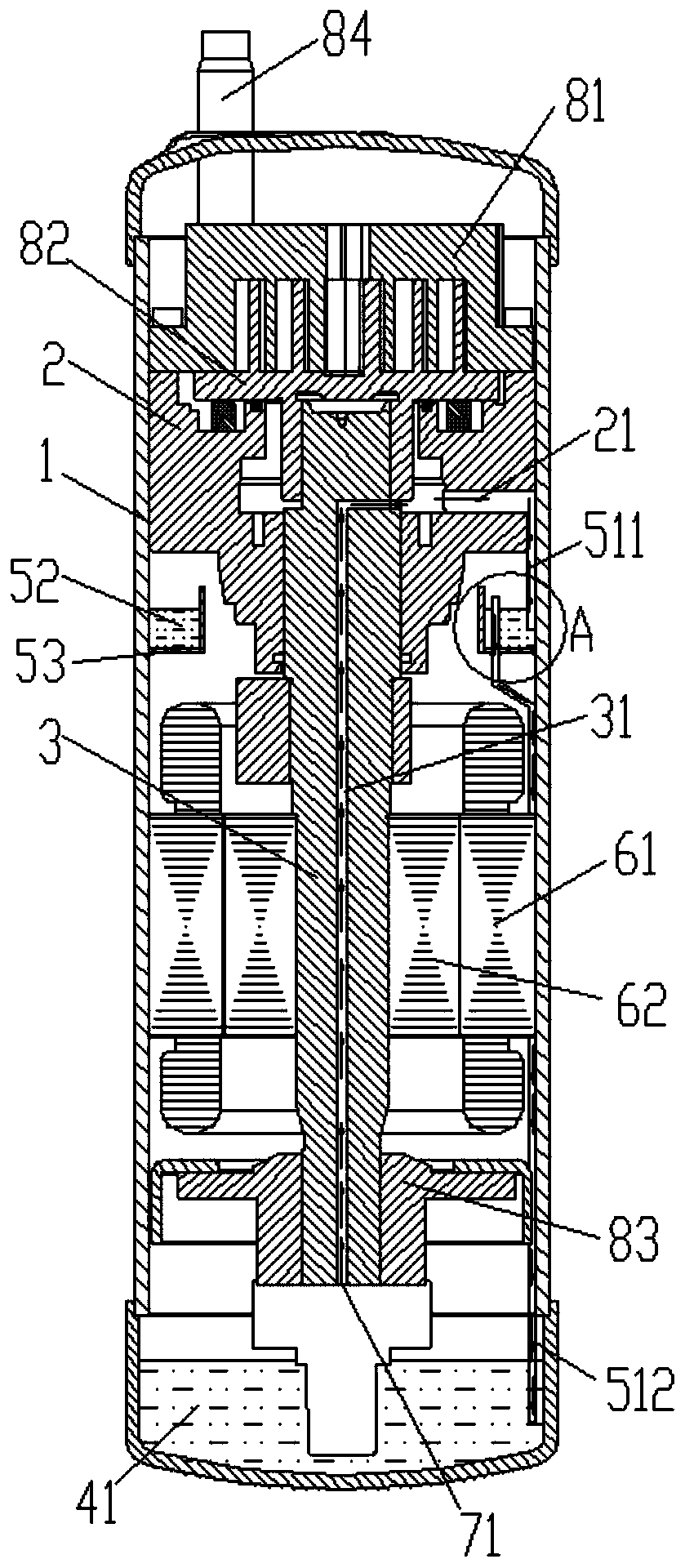

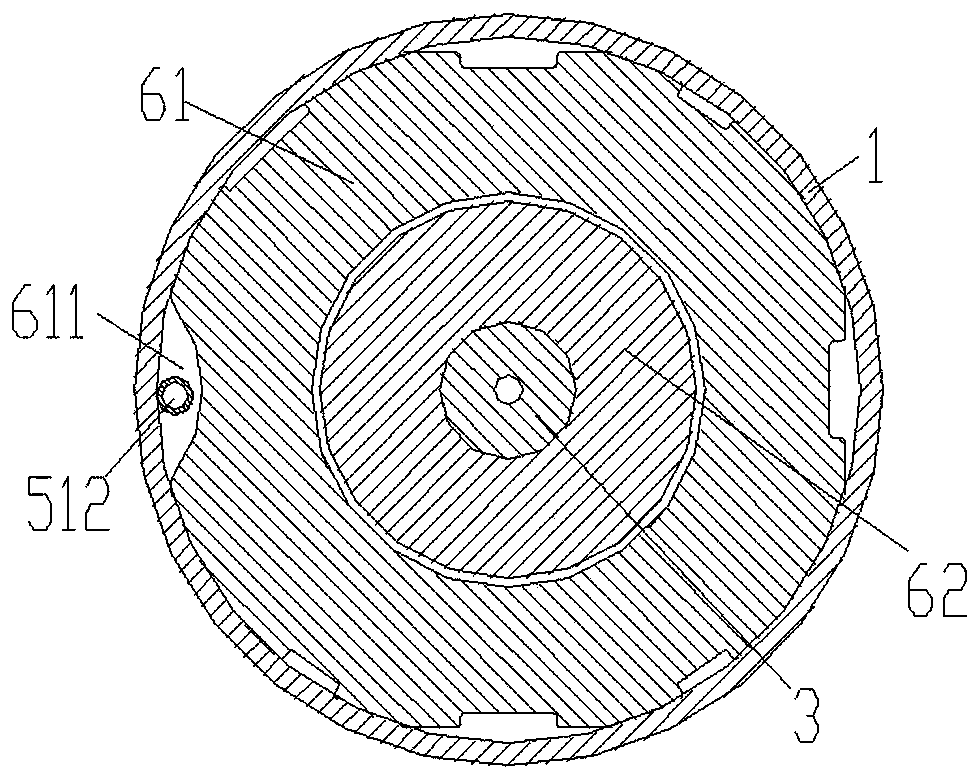

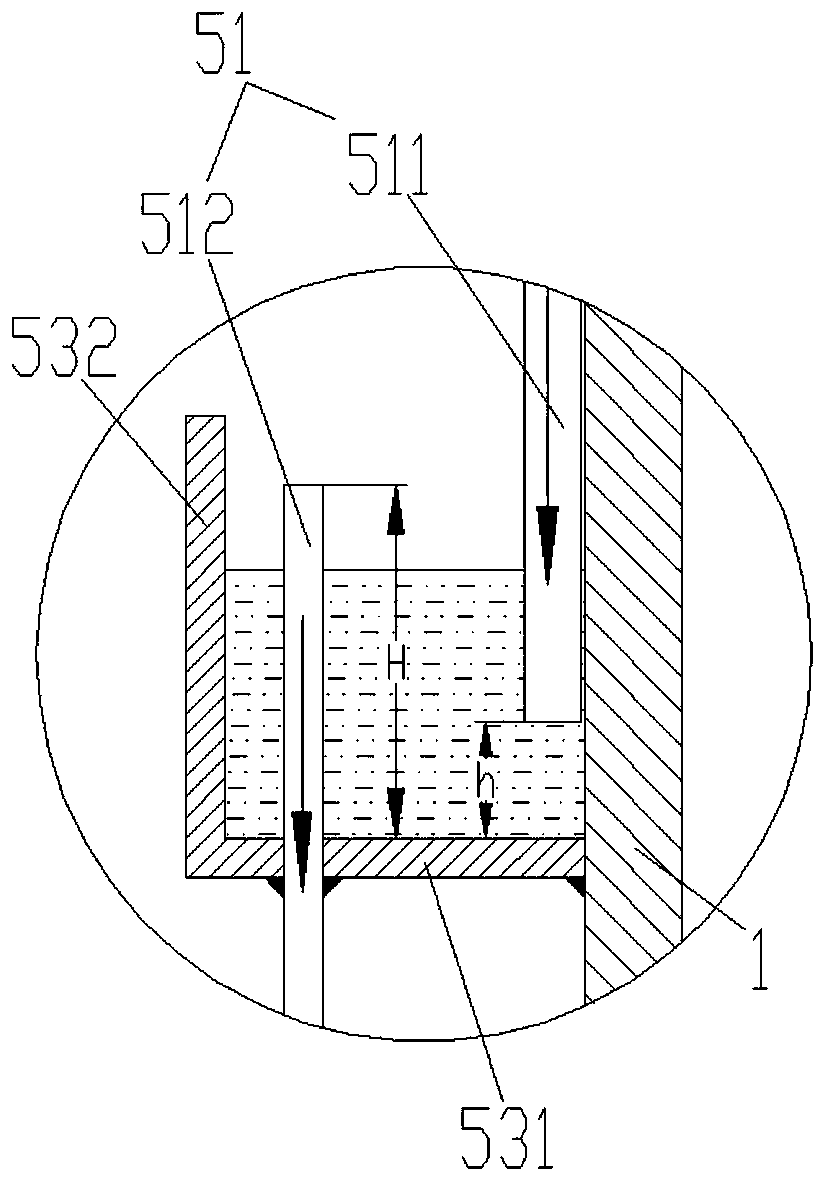

[0020] see in conjunction Figure 1 to Figure 4 As shown, according to the embodiment of the present invention, a compressor lubricating oil return structure is provided, including an outer shell 1, and the outer shell 1 is provided with an upper bracket 2, a crankshaft 3, a lower bracket 83, a fixed scroll 81, a moving Scroll 82 and motor assembly, the bottom of the outer shell 1 is provided with a bottom oil pool 4, the crankshaft 3 is rotatably connected to the upper bracket 2 and the lower bracket 83, and the upper bracket 2 is also used to install The fixed scroll 81 and the movable scroll 82, the motor assembly is used to drive the crankshaft 3 to rotate, and the rotating crankshaft 3 can drive the movable scroll 82 to run (translate) so that the fixed scroll 81 and the moving scroll 82 enters the refrigerant through the intake pipe 84 to form scroll compression. The upper bracket 2 is configured with an oil storage chamber 21. The end of the crankshaft 3 away from the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com