Multilayer laminated film

A technology of laminating film and prism layer, applied in optics, instruments, nonlinear optics, etc., can solve the problems of poor wear resistance of products, adsorption of upper polarizer, poor versatility, etc., to reduce material waste and reduce rainbows the effect of reducing moiré interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

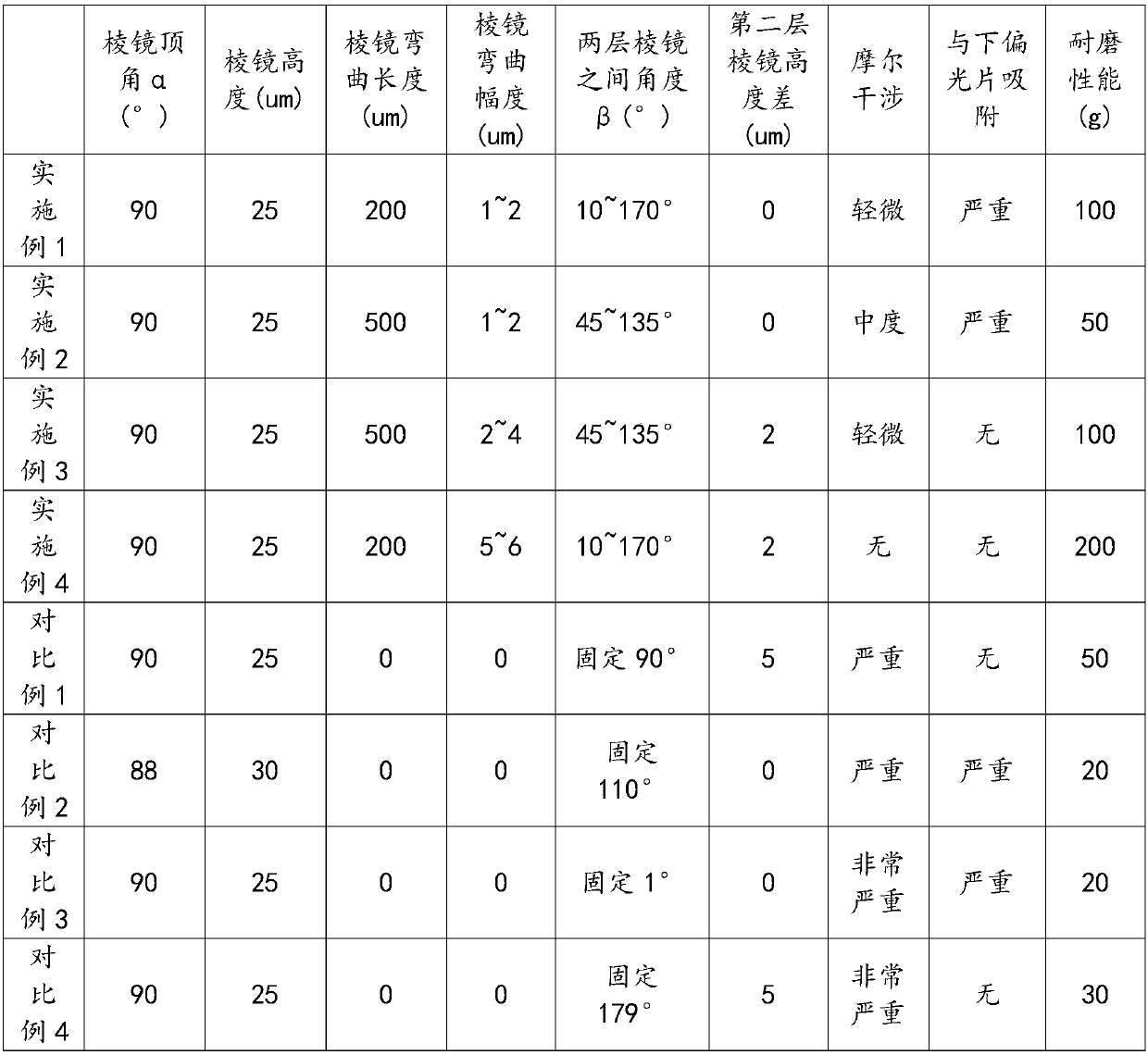

Embodiment 1

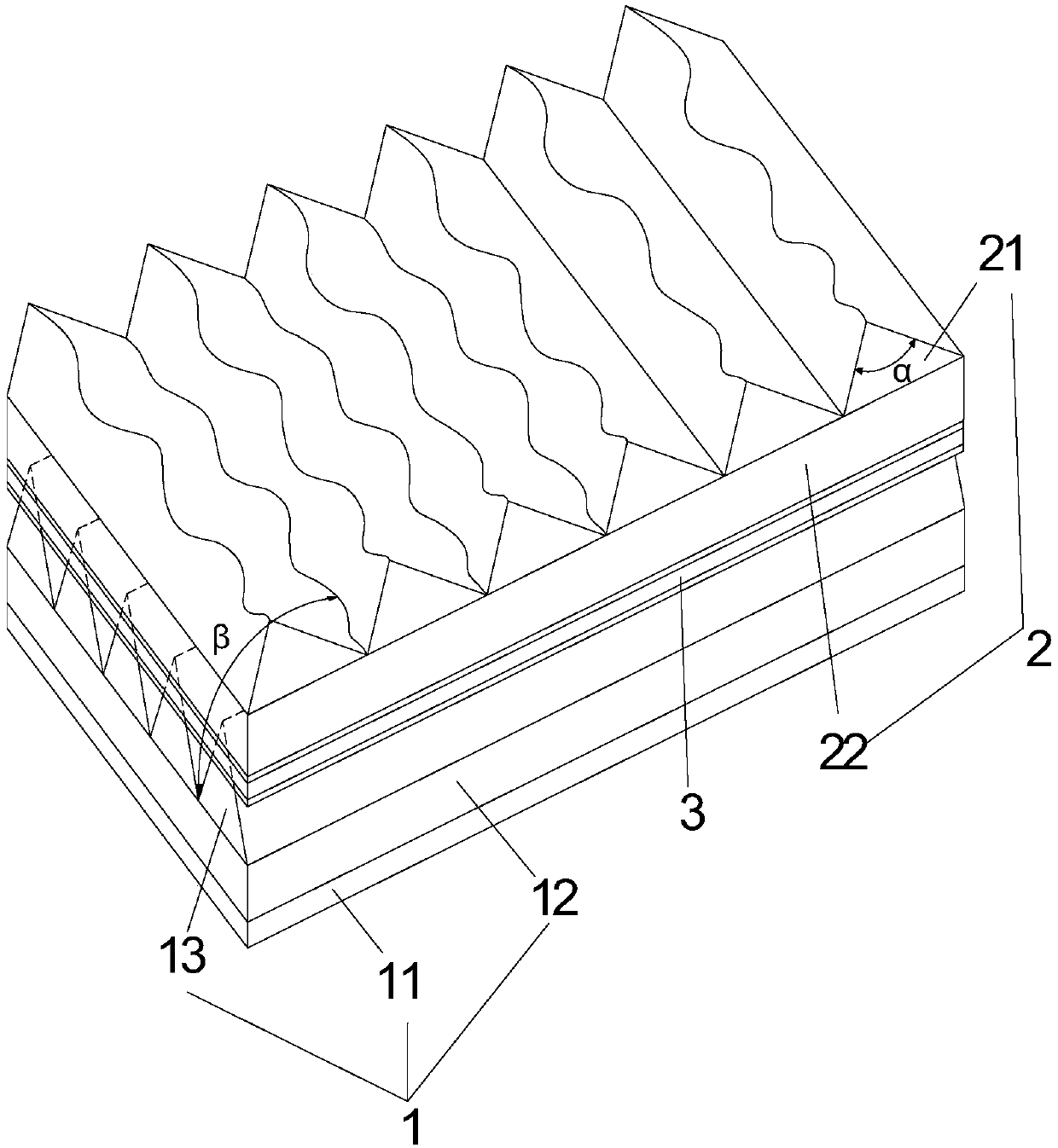

[0019] See attached figure 1 As shown, a kind of multi-layer laminated film in the present embodiment comprises the first prism layer 1 and the second prism layer 2, and the second prism layer passes between the first prism layer 1 and the second prism layer 2 The non-prism structure array surface of the layer is coated with adhesive 3 and bonded together. The above-mentioned adhesive 3 can be transparent, or it can be a fog surface formed by adding particles in the middle. Generally, the thickness of the adhesive is 1-2. 5um, the haze is 0-50%.

[0020] In this embodiment, the line connecting the prism valley bottoms of the first prism layer 1 is a straight line; part of the line connecting the prism valley bottoms of the second prism layer 2 is a wavy curve, and the other part is a straight line. The included angle between the direction of the prism valley bottom of the first prism layer 1 and the direction of the prism valley bottom of the second prism layer 2 is β, and it...

Embodiment 2

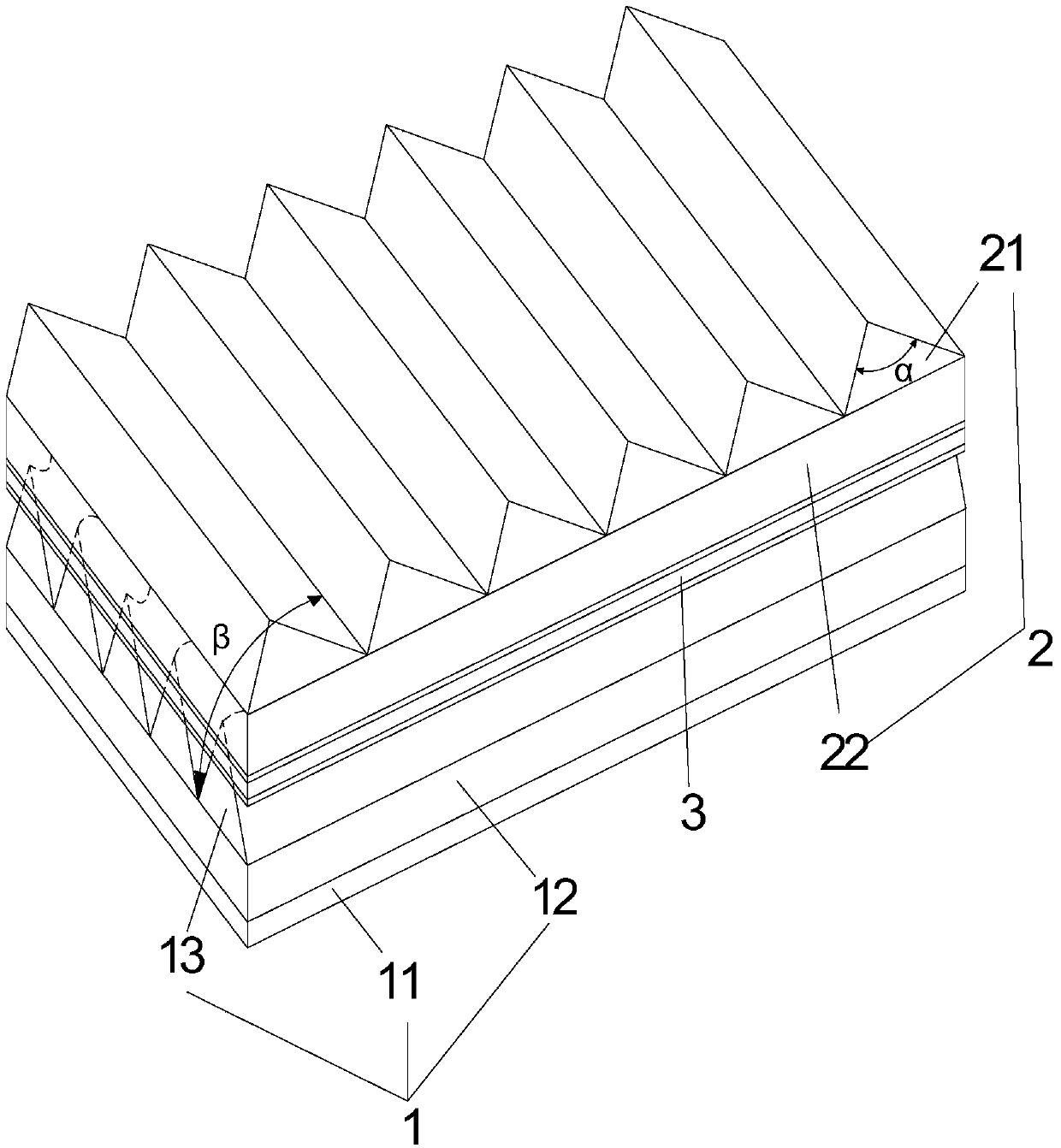

[0029] like figure 2 As shown, this embodiment proposes a multilayer laminated film, which includes a first prism layer 1 and a second prism layer 2, and the second prism layer passes between the first prism layer 1 and the second prism layer 2 The non-prism structure array surface of the layer is coated with adhesive 3 and bonded together. The above-mentioned adhesive 3 can be transparent, or it can be a fog surface formed by adding particles in the middle. Generally, the thickness of the adhesive is 1-2. 5um, the haze is 0-50%.

[0030] The line connecting the prism valley bottoms of the first prism layer 1 is partly a wavy curve and the other part is a straight line; the line connecting the prism valley bottoms of the second prism layer 2 is a straight line. The included angle between the direction of the prism valley bottom of the first prism layer and the direction of the prism valley bottom of the second prism layer is β, and its range is 1°≤β≥179°. Because the connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com