Optical film and backlight unit

An optical film and optical film technology, applied in the optical field, can solve the problems of poor shading of the optical film structure, reduce the light conduction efficiency in the backlight unit, and the influence of the optical film conduction, and achieve the reduction of molar interference, good shading, and improved conduction. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

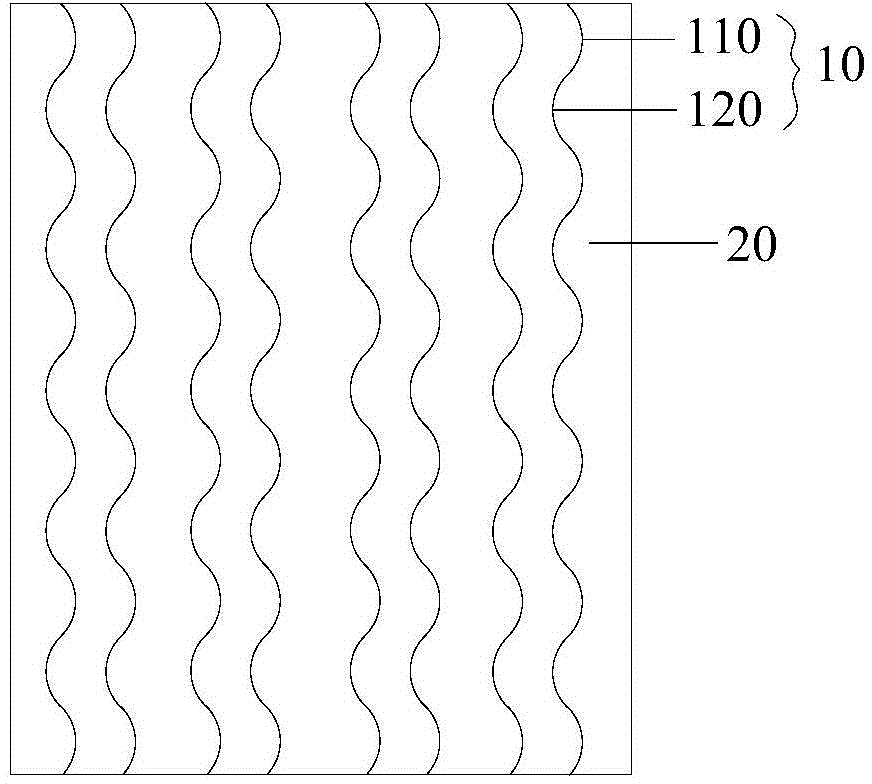

[0051] The optical film provided by this embodiment is as image 3 As shown, the optical film includes a transparent material layer, the transparent material layer is composed of a layer of material preparation layer, and the material of the material preparation layer is an acrylic acid copolymer;

[0052] An air layer is also provided in the transparent material layer, and the air layer is composed of a plurality of air passages arranged sequentially along the a direction, and each air passage in the air layer is arranged at equal intervals in turn, and the air passages run through the transparent material layer along the b direction, and the a direction and The b direction is vertical, and the a direction and the b direction are both parallel to the extended surface of the transparent material layer;

[0053] The air passage has two corresponding side walls bent along the direction b, the two corresponding side walls are symmetrical to each other, and the corresponding side ...

Embodiment 2

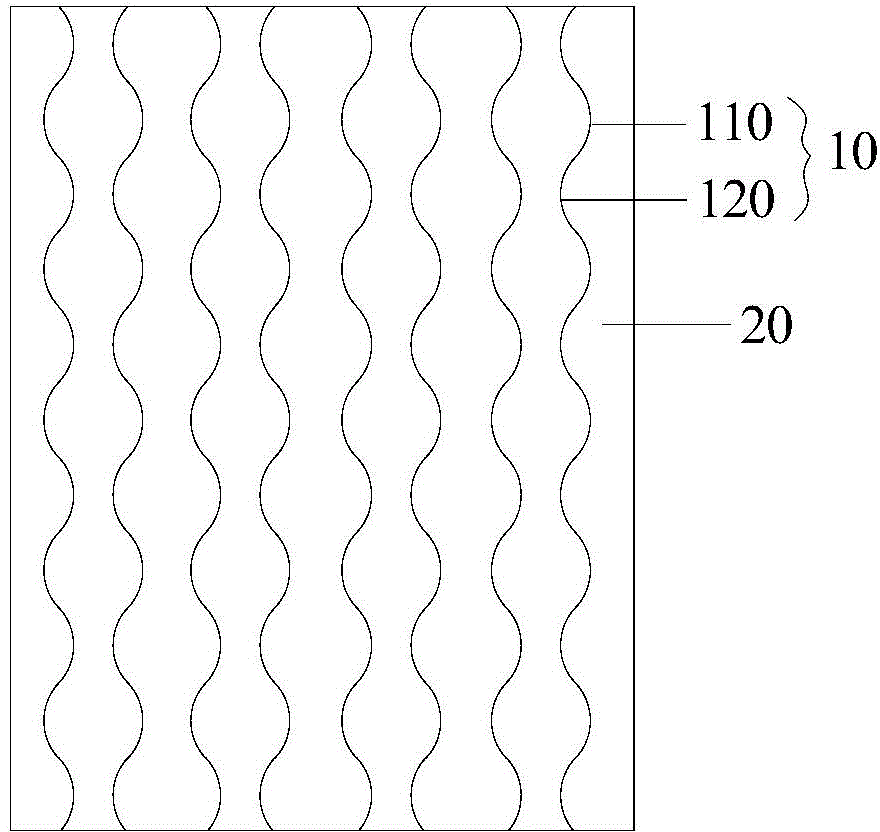

[0056] The optical film provided by this embodiment is as Figure 4 As shown, the optical film includes a transparent material layer, the transparent material layer is composed of a layer of material preparation layer, and the material of the material preparation layer is an acrylic acid copolymer;

[0057] An air layer is also provided in the transparent material layer, and the air layer is composed of a plurality of air passages arranged sequentially along the a direction, and each air passage in the air layer is arranged at equal intervals in turn, and the air passages run through the transparent material layer along the b direction, and the a direction and The b direction is vertical, and the a direction and the b direction are both parallel to the extended surface of the transparent material layer;

[0058] The air channel has two corresponding side walls bent along the b direction, and any section perpendicular to the b direction in each air channel is a first vertical s...

Embodiment 3

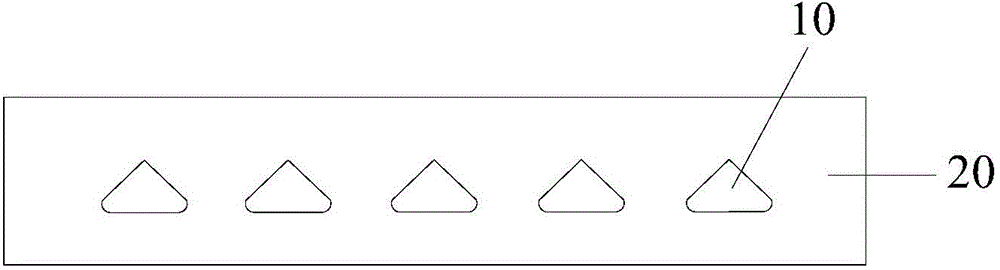

[0061] The optical film provided by this embodiment is as Figure 5 As shown, the optical film includes a transparent material layer, the transparent material layer is composed of a layer of material preparation layer, and the material of the material preparation layer is an acrylic acid copolymer;

[0062] An air layer is also provided in the transparent material layer, and the air layer is composed of a plurality of air passages arranged sequentially along the a direction, and each air passage in the air layer is arranged at equal intervals in turn, and the air passages run through the transparent material layer along the b direction, and the a direction and The b direction is vertical, and the a direction and the b direction are both parallel to the extended surface of the transparent material layer;

[0063] The air passage has two corresponding side walls bent along the direction b, the two corresponding side walls are symmetrical to each other, and the corresponding side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com