Temperature control technology of laser during continuous measurement

A temperature control and temperature controller technology, applied in non-electric variable control, simultaneous control of multiple variables, control/regulation systems, etc., can solve problems such as laser damage and laser heat generation, improve service life and facilitate heat dissipation , to ensure the effect of the use of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

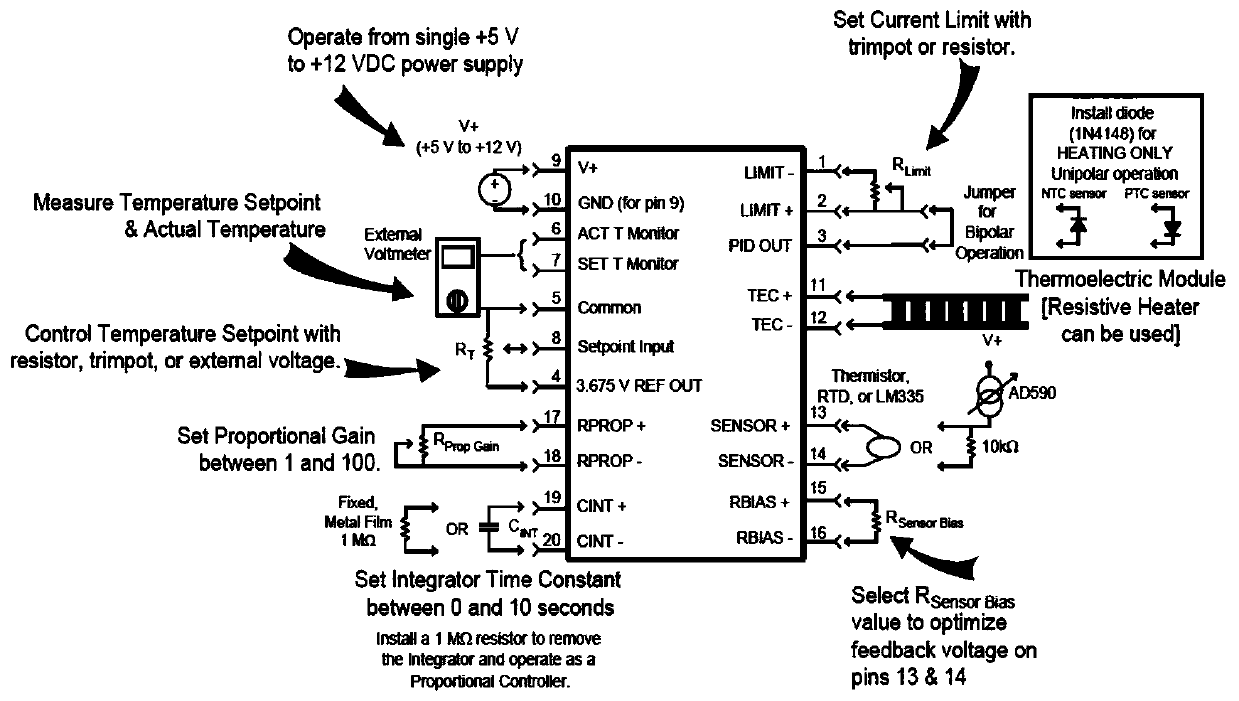

[0019] A temperature control technology for lasers during continuous measurement, the specific steps are as follows: the temperature control part of the laser is completed by a high-performance temperature controller HTC1500, the PI control loop is designed as a bipolar current source, using a resistance temperature sensor and a built-in sensor Bias current, adding a diode to run resistive heaters with unipolar output current, on-board reference voltage simplifies potentiometer control of temperature set point, optional external set point voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com