Pneumatic rebounce type livestock feed crushing and drying device

A drying device and feed technology, applied in the direction of drying gas arrangement, feed, drying, etc., can solve the problems of single structure, inconvenient feeding control, low efficiency, etc., achieve the effect of complete crushing, improve crushing effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

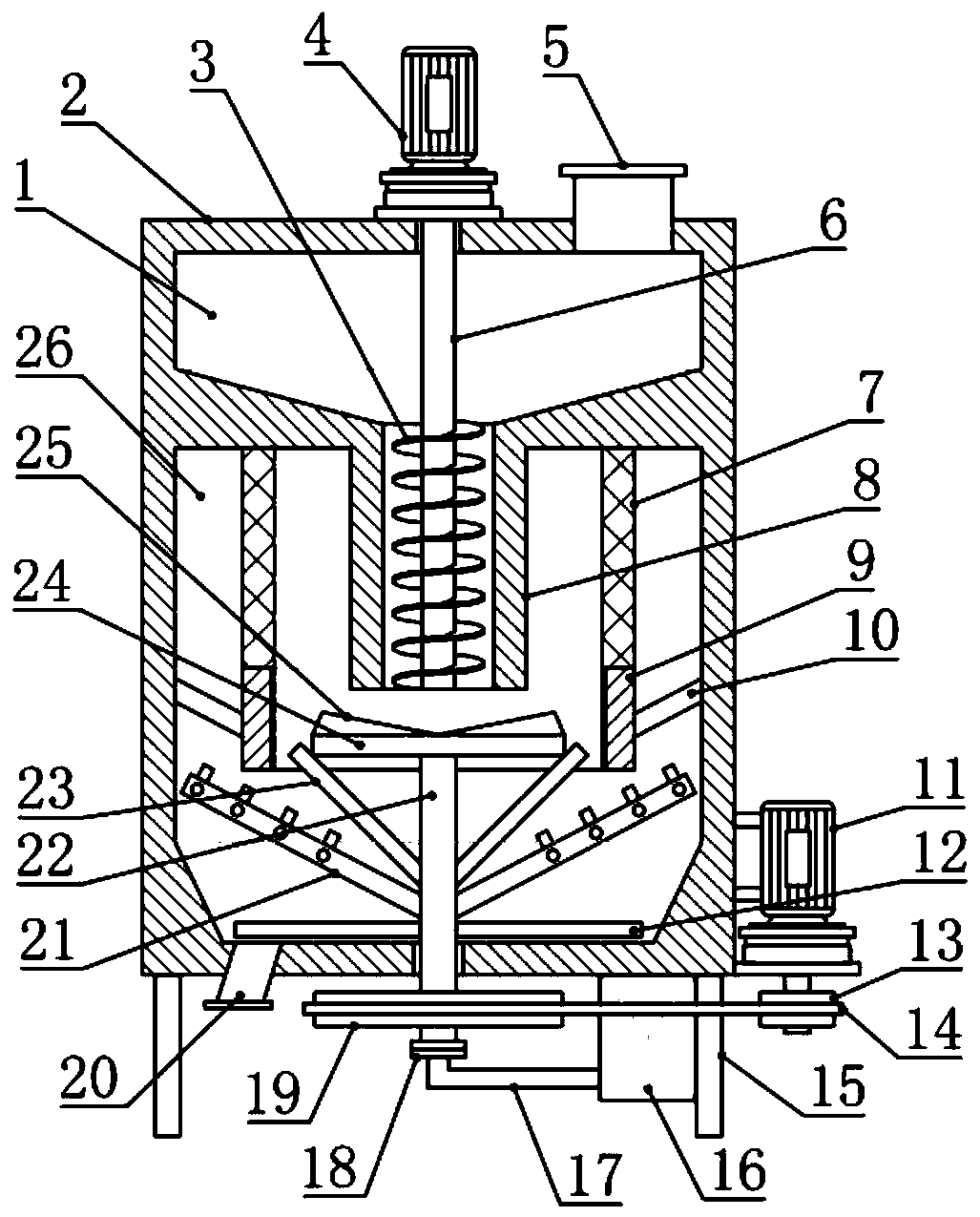

[0020] see figure 1 , in the embodiment of the present invention, a pneumatic rebound type livestock feed crushing and drying device includes a body 2, the upper part of the body 2 is provided with a storage chamber 1, and the bottom of the storage chamber 1 is a conical structure with a downward slope in the middle , the bottom of the body 2 is provided with a processing chamber 26, and a feeding tube 8 is installed in the middle of the top of the processing chamber 26, and the storage chamber 1 communicates with the processing chamber 26 through the inner cavity of the feeding tube 8, and the feeding tube 8 The inner side of the barrel 8 is provided with a feeding shaft 6, and a screw blade 3 is installed on the feeding shaft 6 inside the feeding tube 8, and the screw blade 3 is used to control the feeding, and the feeding shaft 6 is provided by the first The motor 4 is driven to rotate; specifically, the first motor 4 is installed and fixed on the top of the body 2, the out...

Embodiment 2

[0028] see Figure 1-3 , the difference between this embodiment and embodiment 1 is:

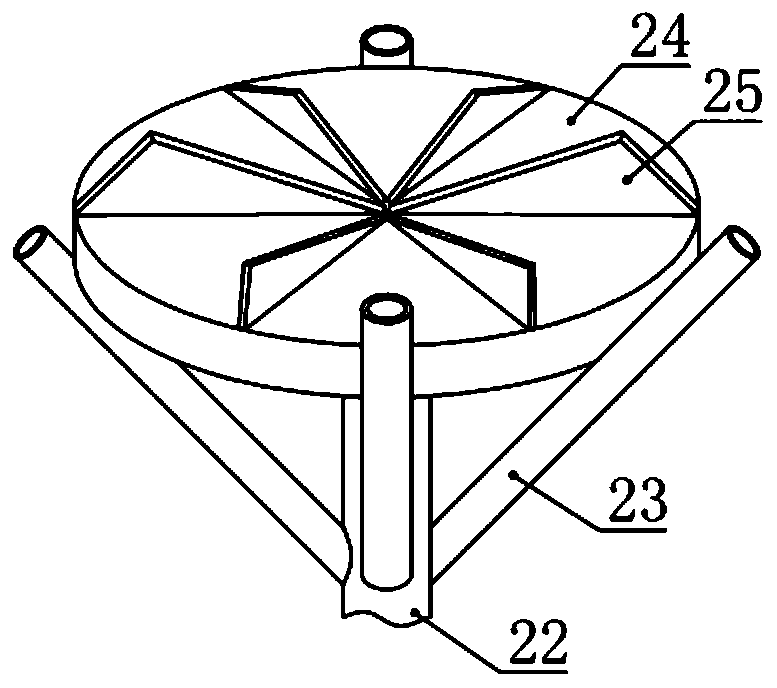

[0029] In this example, if figure 2 As shown, the turntable 24 is a disc-shaped structure arranged horizontally, the diameter of the turntable 24 is smaller than the inner diameter of the retaining cylinder 9, the diameter of the turntable 24 is greater than the inner diameter of the delivery barrel 8, and the crushing knife 25 is a right-angled triangle structure, The crushing knife 25 is vertically fixed on the top of the rotating disk 24, the length of the hypotenuse of the crushing knife 25 is the same as the radius of the rotating disk 24, and the hypotenuse of the crushing knife 25 is fixed on the top of the rotating disk 24, and the crushing knife 25 has a better feed Broken effect.

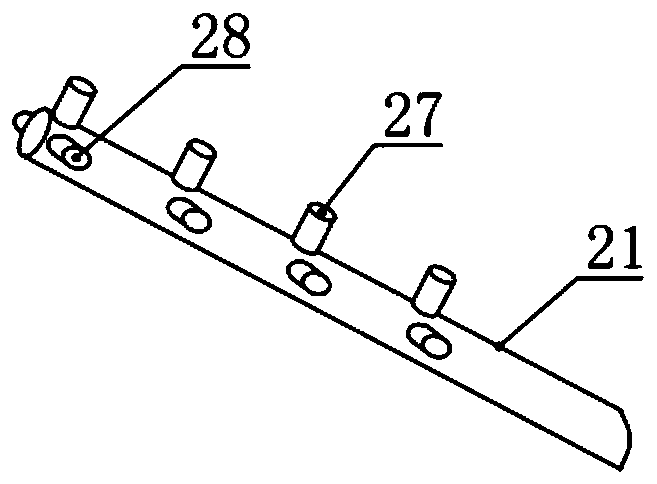

[0030] In this example, if image 3 As shown, the outer end of the crushing rod 21 is set at an angle of 30° upward, the outer end of the crushing rod 21 is located at the outer lower part of the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com