Method and apparatus for producing gypsum hollow block

A technology of hollow block and production method, which is applied in the field of gypsum block and gypsum hollow block, can solve the problems of difficult temperature control, low drying success rate, long drying time, etc., and achieve uniform and fast mixing and high drying efficiency , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

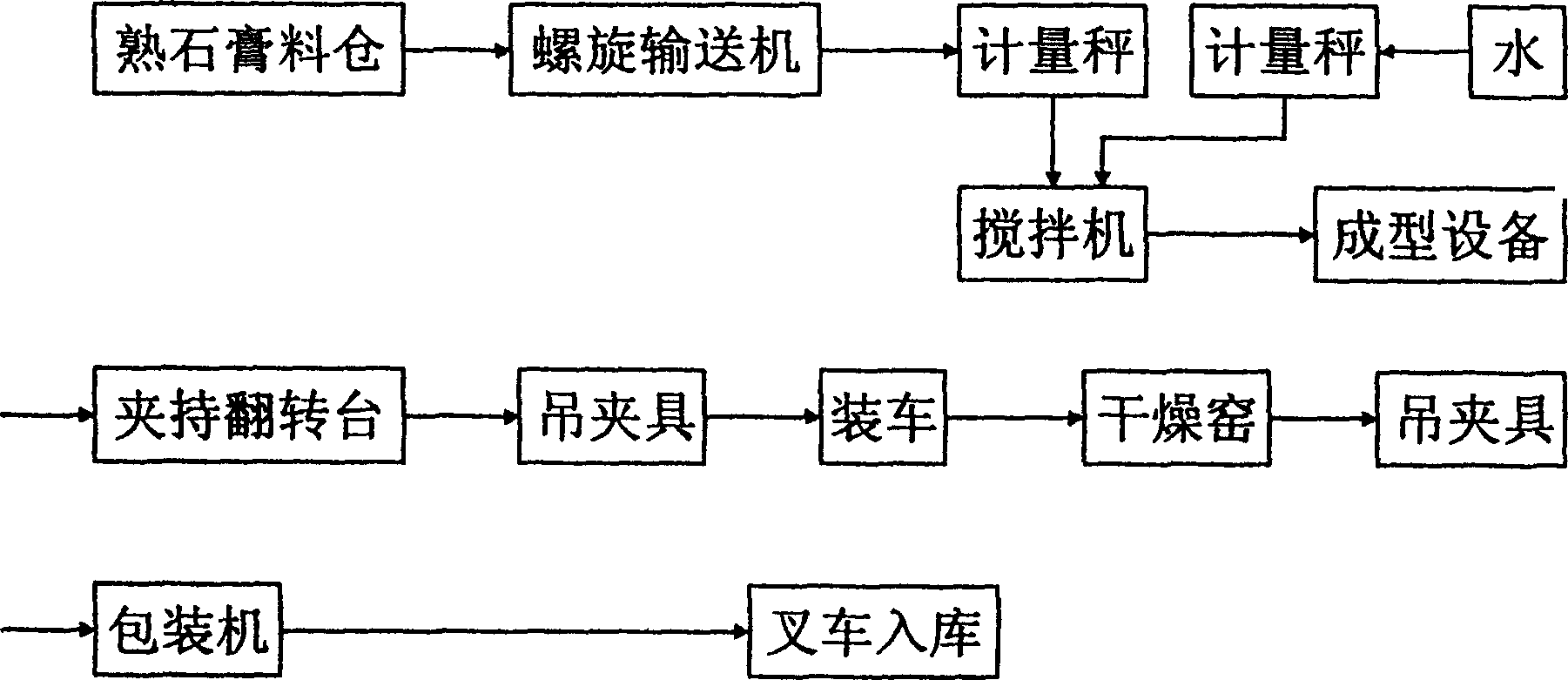

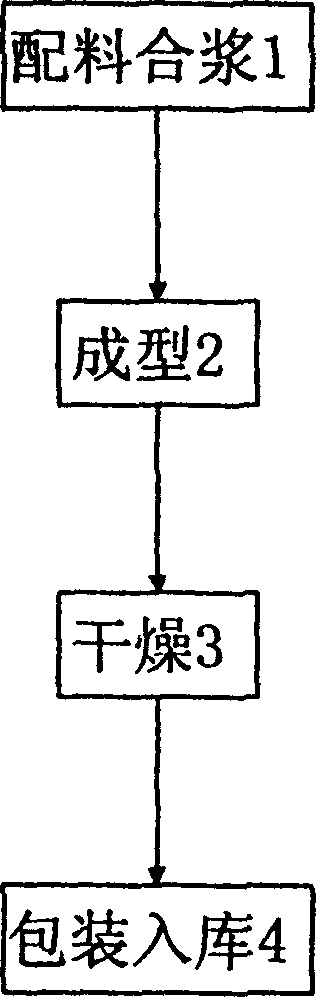

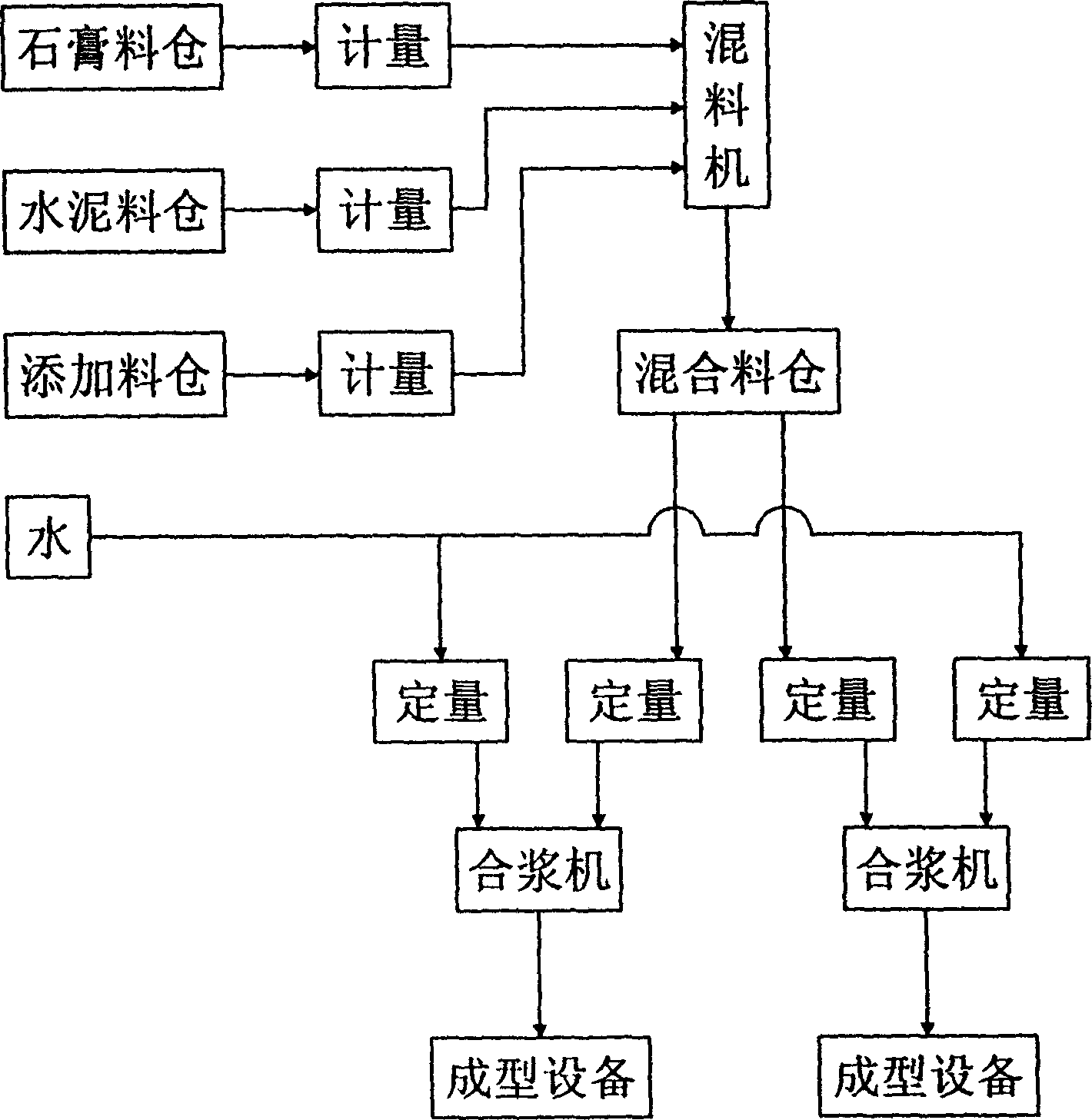

[0017] see figure 2 , the production method includes four steps of batching and mixing 1, forming 2, drying 3 and packaging and warehousing 4, the raw materials used in the production of gypsum hollow blocks are sent into plastic flowing gypsum slurry through batching and mixing 1 water, and the flowing The gypsum slurry is processed into a hollow block of a certain shape by casting 2, and then processed into a finished gypsum hollow block after being dried 3 and packaged and put into storage 4. see you again image 3 , the batching slurry 1 is that the various raw materials for the production of gypsum hollow blocks are transported, extracted and stirred into a uniform mixture according to a certain proportion, stored for use, and then quantitatively measured The mixture, and a certain proportion of The process of high-speed stirring with water to form plastic flow gypsum slurry. The various raw materials for producing gypsum hollow blocks include gypsum, cement and relate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com