Side discharge spiral classifier for mineral dressing

A discharge screw and classifier technology, applied in solid separation, wet separation, sieve and other directions, can solve the problems of adjusting screw design protection structure, adjusting screw thread damage, inconvenience in practical use, etc., to reduce thrust, lighten The effect of thread damage and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

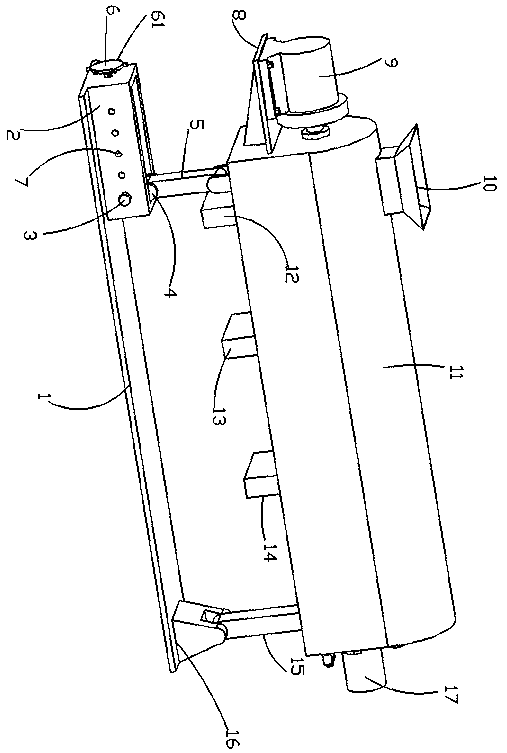

[0032] Such as figure 1 and figure 2 As shown, a side discharge spiral classifier for mineral processing in this embodiment includes a base plate 1, a motor 9, a feed hopper 10, a frame 11 and a spiral body 19, and the left and right ends of the top of the base plate 1 are respectively fixedly connected with loops. The word frame 2 and the fixed U-shaped block 16, the back word frame 2 are threadedly connected with a threaded rod 19 through a threaded hole, and the outer end of the threaded rod 19 is fixedly connected with a rotating structure. Push rod 61 is arranged, and the inner end of threaded rod 19 is rotatably connected with movable U-shaped block 4 through fixedly connected bearings, and a limit structure is arranged between the movable U-shaped block 4 and the back frame 2, and the limit structure includes lock pin 3 and adjustment Hole 7, the front and rear side walls of the back frame 2 are evenly provided with adjustment holes 7, the lock pin 3 passes through th...

Embodiment 2

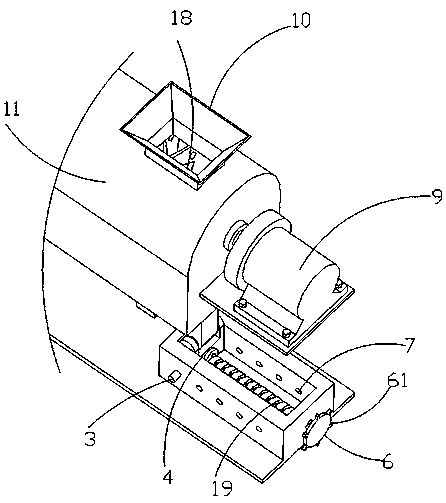

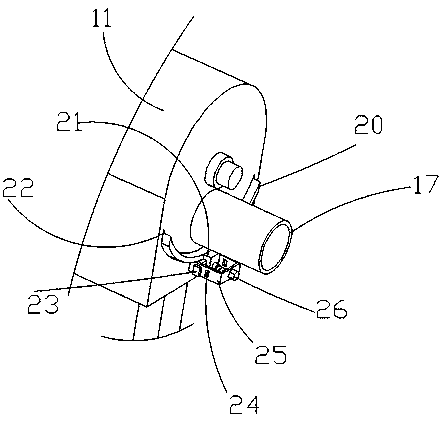

[0035] Embodiment two is a further improvement on embodiment one. Such as figure 1 , 3 , 4 and 5, a feed hopper 10 is fixedly connected to the through hole at the left end of the top of the frame 11, a mounting plate 8 is fixedly connected to the left end of the frame 11, and a motor 9 is fixedly installed on the top of the mounting plate 8, and the motor 9 is connected to the external power supply Electricity 1 connection, the output end of the motor 9 is fixedly connected with a spiral body 19, and the two ends of the spiral body 19 are fixedly connected with the frame 11 through fixedly connected bearings, and the lower end of the grading sieve plate of the frame 11 is uniformly provided with a small discharge hole 27 , medium discharge hole 28 and large discharge hole 29, the right end of the frame 11 is provided with an arc groove 22, an arc plate 20 is slidably connected in the arc groove 22, and the arc plate 20 is uniformly provided with a small The through hole 201,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com