Height self-adjusting type steel pipe notching machine

A technology of self-adjusting and grooving machine, which is applied in the field of height self-adjusting steel pipe grooving machine, can solve problems such as difficulty in ensuring levelness, low adjustment efficiency, and high labor intensity, so as to ensure the quality of grooving, reduce labor intensity, Design scientific and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

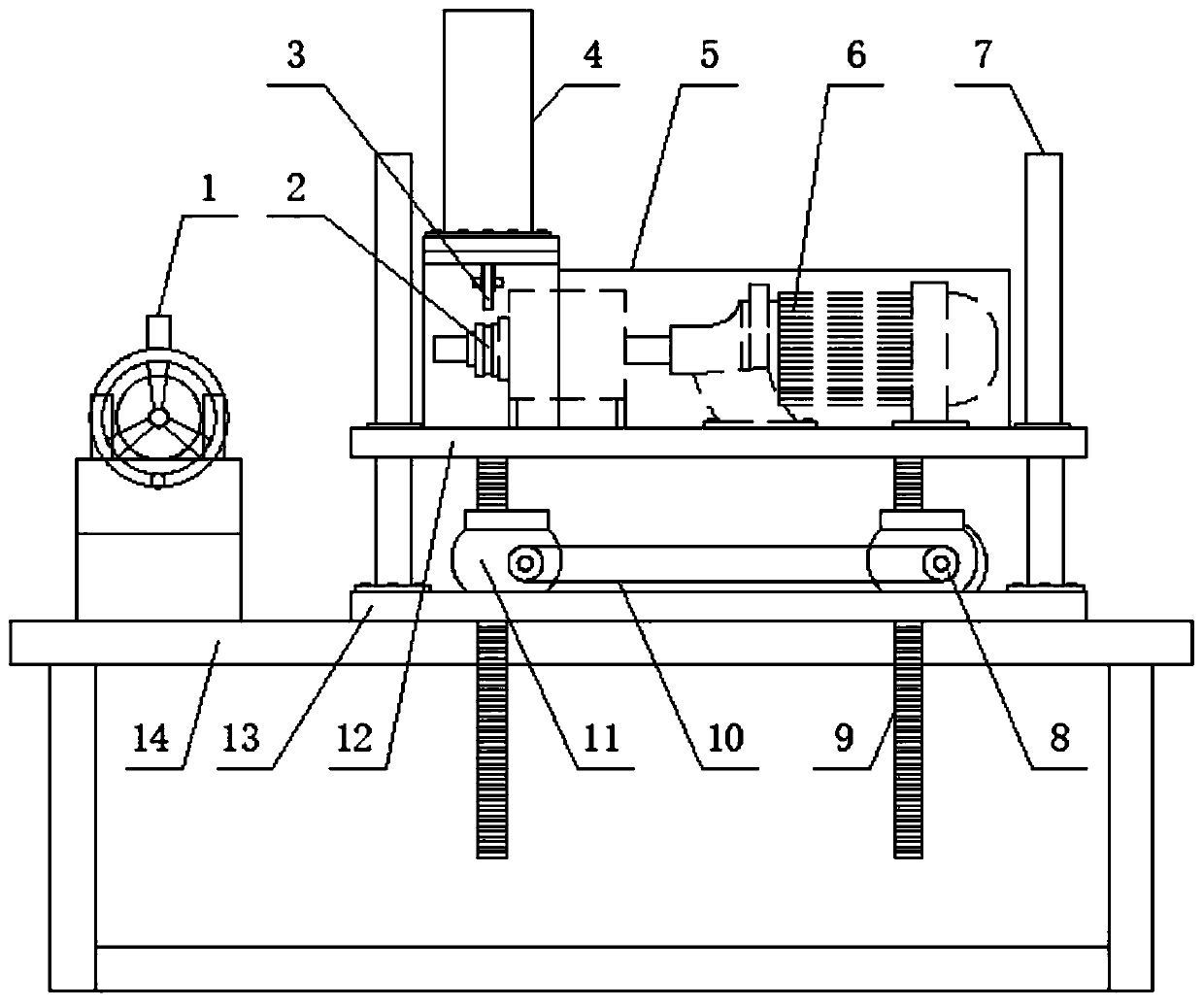

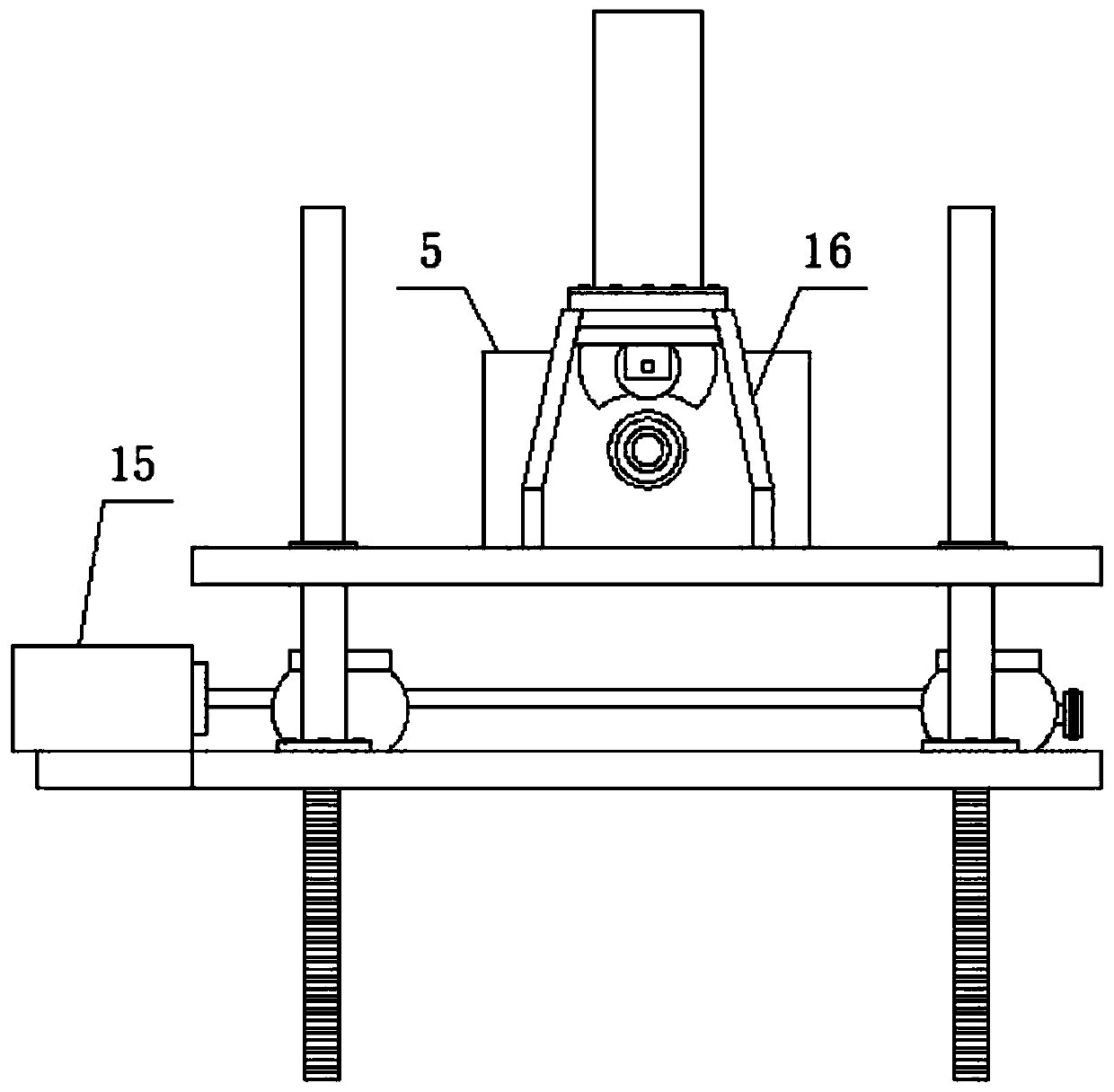

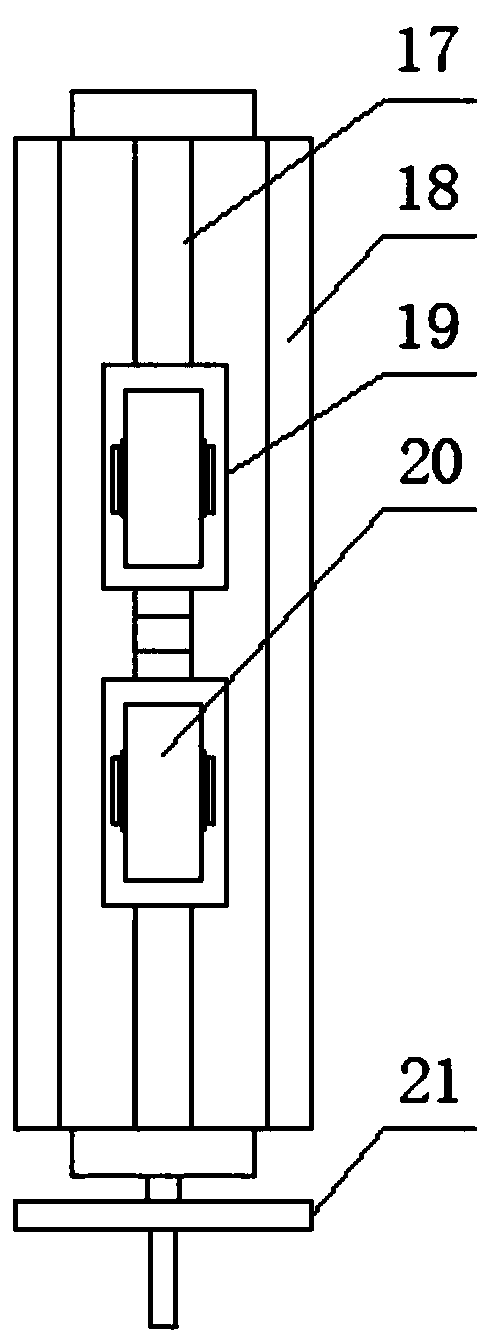

[0022] A height self-adjusting steel pipe grooving machine, including a working frame 14, a trusteeship mechanism 1 and a grooving mechanism, and a trusteeship mechanism and a grooving mechanism are arranged opposite to each other on the left and right of the working frame. The innovation is that it also includes The automatic lifting mechanism installed on the lower part of the pressure groove mechanism, the automatic lifting mechanism is composed of a fixed bottom plate 13, a lifting top plate 12, a guide column 7, a lead screw 9, an active lifting drive group and a driven lifting drive group. The bottom plate is fixed on the working frame, and guide columns are vertically arranged at the four corners of the upper end surface of the fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com