Assembly type rounding and supporting automatic equipment for pressure steel pipe tiles

A technology of automation equipment and pressure steel pipes, which is applied in the direction of measuring devices, handheld tools, optical devices, etc., and can solve the problems of small application range of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

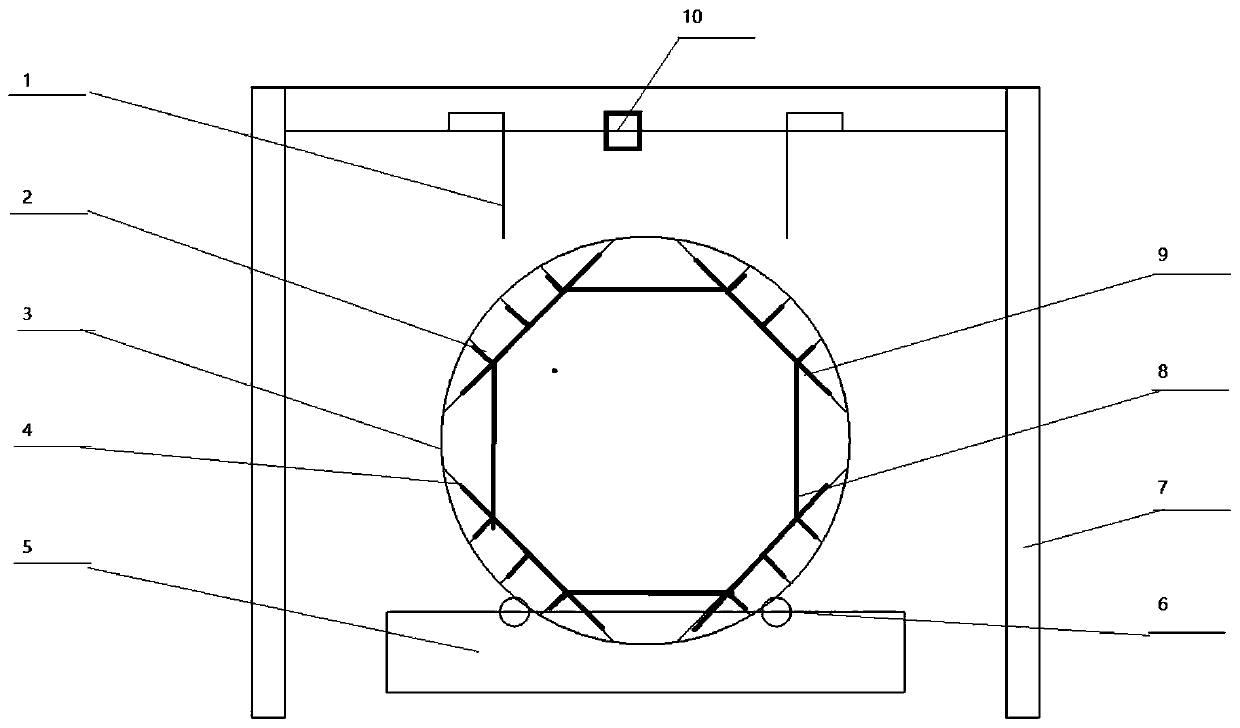

[0025] An automatic equipment for assembly-type circular support of pressure steel pipe tiles, including a rotary trolley and hoisting equipment arranged above the rotary trolley, and also includes a two-way adjusting core rod. The two-way adjusting core rod includes a core rod fixing rod and a The core rod telescopic adjustment two-way jack at both ends of the core rod fixed rod, the core rod telescopic adjustment two-way jack can be stretched along the length direction of the core rod fixed rod, the movable end of the core rod telescopic adjustment two-way jack is installed with a steel pipe tile for locking The buckle of the sheet, and the core rod connecting rod is also connected between the core rod fixing rods, and the core rod connecting rod and the core rod fixing rod are connected to form an inscribed polygon with the same number of steel pipe tiles.

Embodiment 2

[0027] On the basis of Example 1, a number of arc height adjusting two-way jacks for automatically adjusting the roundness of the steel pipe tiles are distributed along the arc chord of the steel pipe tile on the fixed rod of the core rod, and the movable end of the arc height adjusting two-way jack is A card grabbing mechanism for grabbing the arc edge of the steel pipe tile is installed.

Embodiment 3

[0029] On the basis of the above embodiments, the hoisting equipment includes a support frame and two sets of electric lifting mechanisms arranged on the support frame, and a laser profile detector is also provided on the support frame between the electric lifting mechanisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com