A ceramic irrigation membrane preparation mold and gradient ceramic irrigation membrane preparation process

A preparation process and ceramic technology, applied in the field of gradient ceramic irrigation membranes, can solve the problem of not being able to ensure the bonding strength of the ceramic membrane support body and the membrane layer at the same time, filtration flux, etc. resistance, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

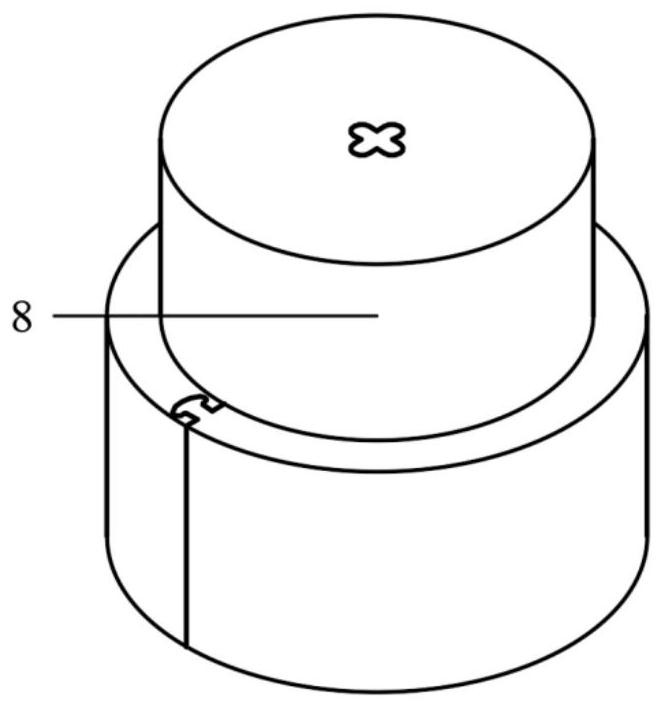

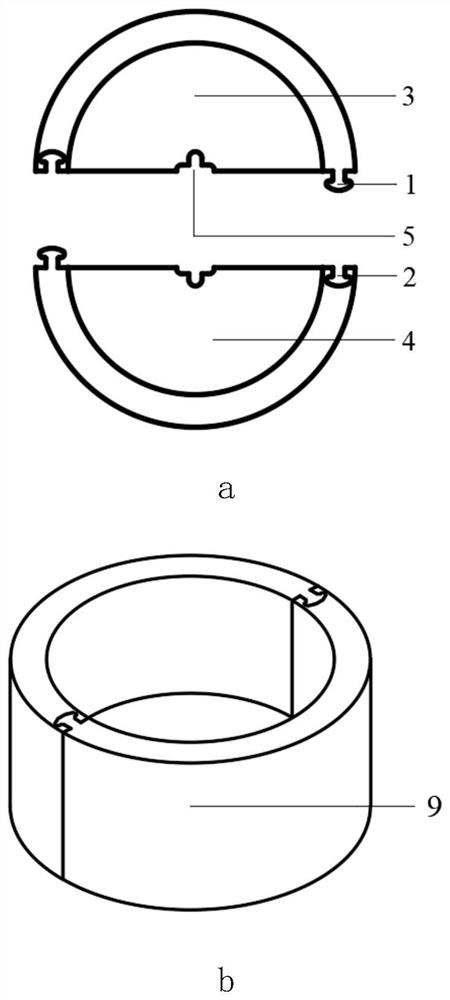

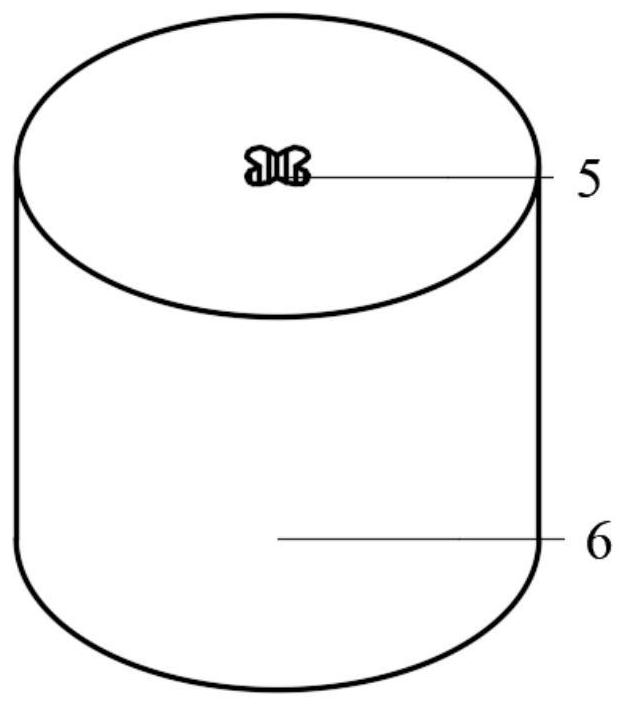

[0036] Comply with the above technical solutions, such as Figure 1 to Figure 5 As shown, this embodiment provides a ceramic irrigation membrane preparation mold, which is composed of an outer mold 8 , an inner core 7 and a pressure rod 6 . The outer mold 8 is structural steel, which is a circular cylindrical structure with a bottom on one side. Its overall height h1, base height h2 and inner diameter d1 are determined according to the thickness and diameter of the prepared ceramic body, and its outer diameter d2 and inner diameter d1 The difference is about 10mm-20mm. The outer mold is composed of the first mold body 3 and the second mold body 4. The shape and size of the first mold body 3 and the second mold body 4 are exactly the same. Generally, the overall height h1 can be set to 50mm, and the height of the base h2 can be set to 20mm. Outer slide rails and inner slide rails are designed at the semicircle of the first mold body 3 and the second mold body 4, and the shape...

Embodiment 2

[0038] This embodiment provides a kind of porous SiO2 for irrigation 2 / Si 3 N 4A preparation method for gradient ceramics, comprising the steps of:

[0039] Step 1, first prepare the slurry and precursor powder:

[0040] (1) First, cheap sodium carboxymethyl cellulose, silica sol, talcum powder (800 mesh), deionized water, Si 3 N 4 The powder (600 mesh) was mixed according to the proportion to make a slurry, then an appropriate dispersant was added, the slurry was prepared by ball milling, the resulting slurry was sealed in an Erlenmeyer flask, and the ultrasonic oscillator was used to vibrate and mix at a frequency of 40kHz for 6h After that, place it in the Erlenmeyer flask for subsequent use;

[0041] (2) SiO 2 Powder (325 mesh), Si 3 N 4 Powder (600 mesh), talcum powder (800 mesh), Al 2 o 3 The powder (400 mesh) was mixed according to a certain ratio, and the mixed powder 0 was obtained by ball milling for 24 hours in a vacuum ball mill (rotation speed: 240r / min...

Embodiment 3

[0051] This embodiment provides a kind of porous SiO2 for irrigation 2 / Si 3 N 4 A preparation method for gradient ceramics, comprising the steps of:

[0052] Step 1, first prepare the slurry and precursor powder:

[0053] (1) First, 10g sodium carboxymethyl cellulose, 30g talcum powder (800 mesh), 10g Si 3 N 4 The powder (600 mesh) is mixed according to the proportion to make powder, and the resulting mixture powder is placed in the alumina tank of the ball mill, and 15-25 agate beads with a diameter of 8-12mm are added, and then the rotation speed of the ball mill is adjusted to 240r / min. The revolution speed was 360r / min, and ball milled for 2h to prepare ceramic powder. Add 20mL of deionized water, 20mL of silica sol and 5g of sodium citrate to the obtained ceramic powder, and after mixing, seal the slurry in a Erlenmeyer flask, vibrate and mix for 6 hours at a frequency of 40kHz with an ultrasonic oscillator, and then place it in a conical Reserve in a shaped bottle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com