Mold rotation system for autoclave products

A technology for autoclave and products, which is applied in the field of mold rotation system for autoclave products, to achieve the effects of uniform molding, reduced measurement, and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The connection structure of the present invention will be described in detail below with reference to the drawings and embodiments.

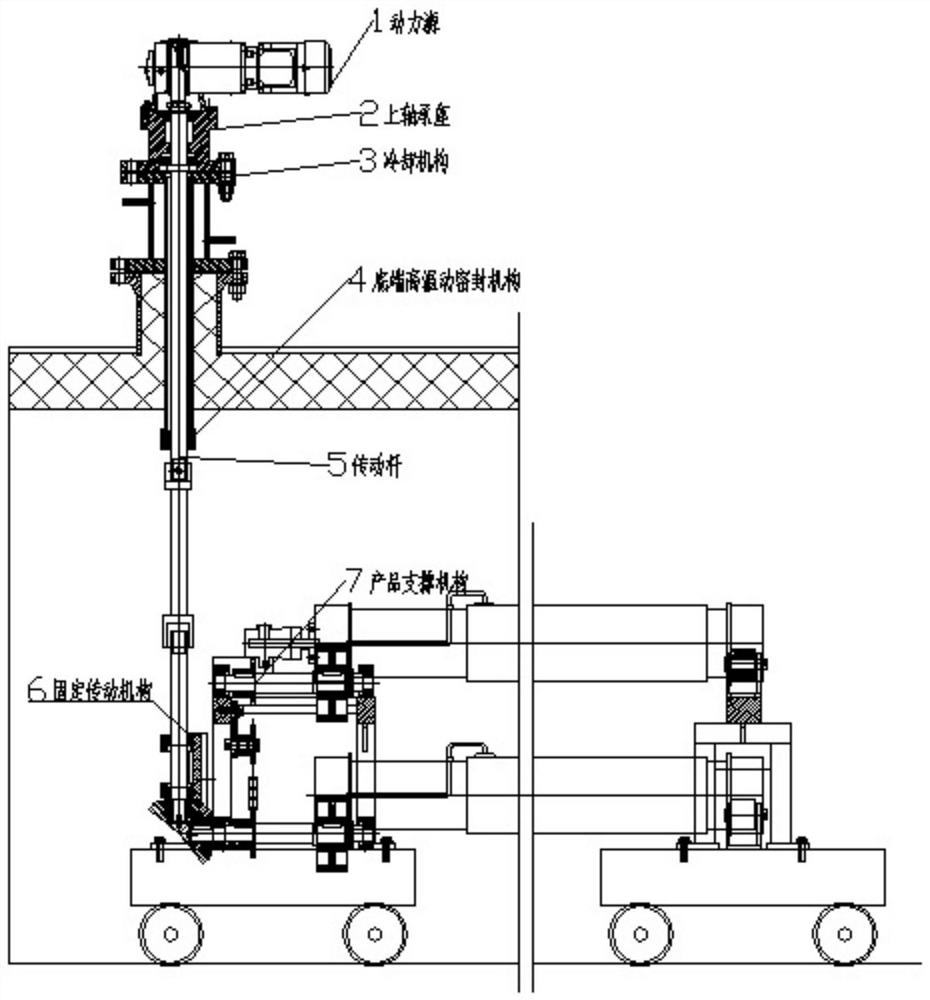

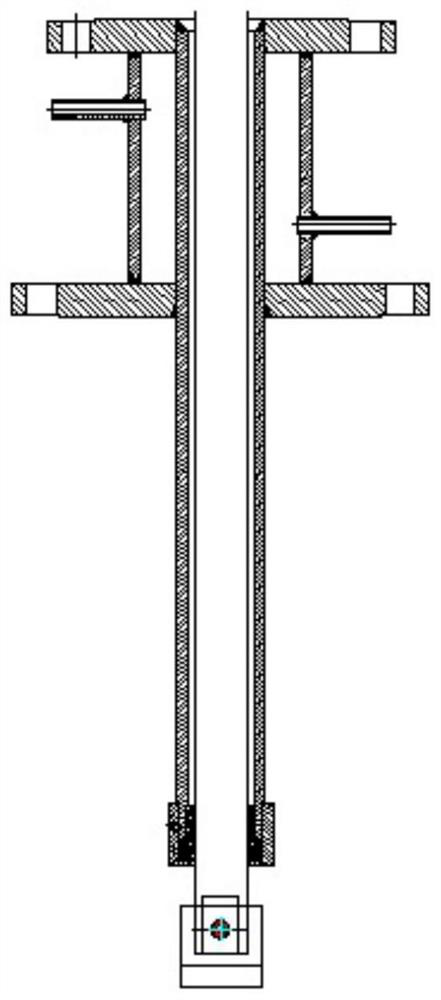

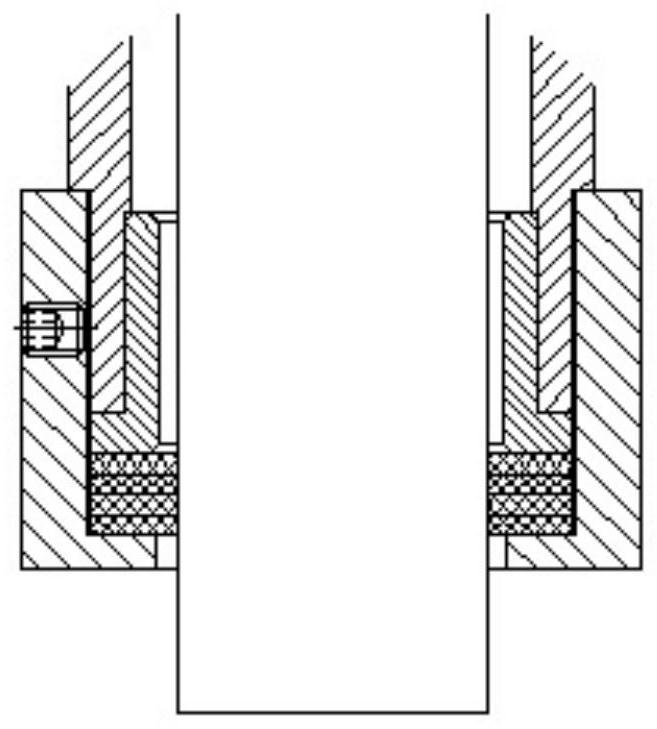

[0028] See attached figure 1 , autoclave product mold rotation system, including power source 1, upper bearing seat 2, cooling mechanism 3, bottom high-temperature dynamic sealing mechanism 4, transmission rod 5, fixed transmission mechanism 6 and product support mechanism 7; wherein power source 1 is The frequency conversion reducer, the frequency conversion reducer and the transmission rod 5 are connected by pin keys to eliminate the expansion and contraction of the transmission rod 5 due to heat; the frequency conversion reducer and the upper bearing seat 2 are fixed by positioning bolts, and the transmission rod 5 and the upper end of the upper bearing seat 2 pass through The upper bearing, the bearing retaining ring and the lock nut are mutually fixed in position. The transmission rod 5 and the lower end of the upper bearing seat 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com