Sludge treatment device and use method thereof

A technology for sludge treatment and treatment equipment, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, separation methods, etc., and can solve problems such as different sludge properties, environmental pollution, and difficult solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

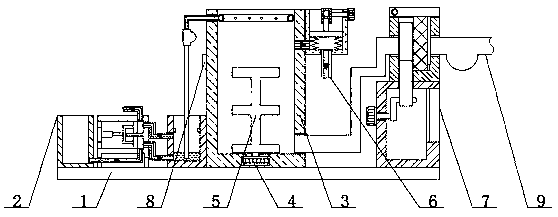

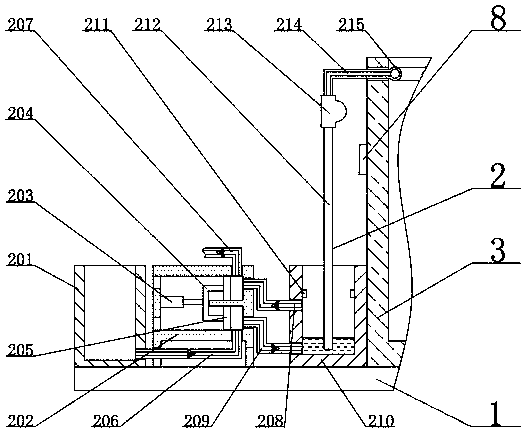

[0034] seefigure 1 , image 3 , Figure 4 , Figure 6 and Figure 7 , the present invention provides a technical solution:

[0035] A sludge treatment device, including a base 1, a treatment device 2, a dosing device 6 and a filter device 7, a treatment device 2 is provided on the left side of the top of the base 1, and the treatment device 2 includes a collection box 201, a fixed frame 202, a first motorized Telescopic rod 203, connecting rod 204, piston plate 205, collection pipe 206, medicine inlet pipe 207, medicine outlet pipe 208, medicine pumping pipe 209, treatment box 210, detector 211, air outlet pipe 212, air pump 213, air inlet pipe 214 and Air hole 215, base 1 top left side is fixedly connected with collection box 201, and this setting is convenient to storage used processing agent, and collection box 201 right end is provided with fixed frame 202, and fixed frame 202 is fixedly connected with base 1, fixes The inner side of the left end face of the frame 202 ...

Embodiment 2

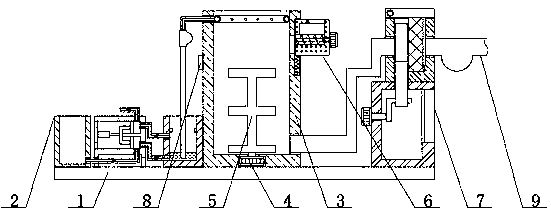

[0039] see figure 2 , image 3 , Figure 5 , Figure 6 and Figure 7 , the present invention provides a technical solution:

[0040] The top of the right side of the sludge tank 3 is provided with a dosing device 6, and the dosing device 6 includes a second medicine box 610, a third motor 611, a spiral blade 612, a first box cover 613, a second spring 614, a pressure plate 615 and a pressure sensor 616, a second medicine box 610 is slidably connected to the top of the right end surface of the sludge tank 3, and the second medicine box 610 runs through the sludge tank 3, and a third motor 611 is fixedly connected to the right end surface of the second medicine box 610, and the third motor 611 The main shaft of the third motor 611 runs through the second medicine box 610, the main shaft of the third motor 611 is connected to the second medicine box 610 in rotation, the end of the main shaft of the third motor 611 is fixedly connected with a helical blade 612, and the helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com