Heating device and method for graphite anode in rare earth molten salt electrolysis

A technology of graphite anode and molten salt electrolysis, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of large energy loss and thinning of graphite anode consumption, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

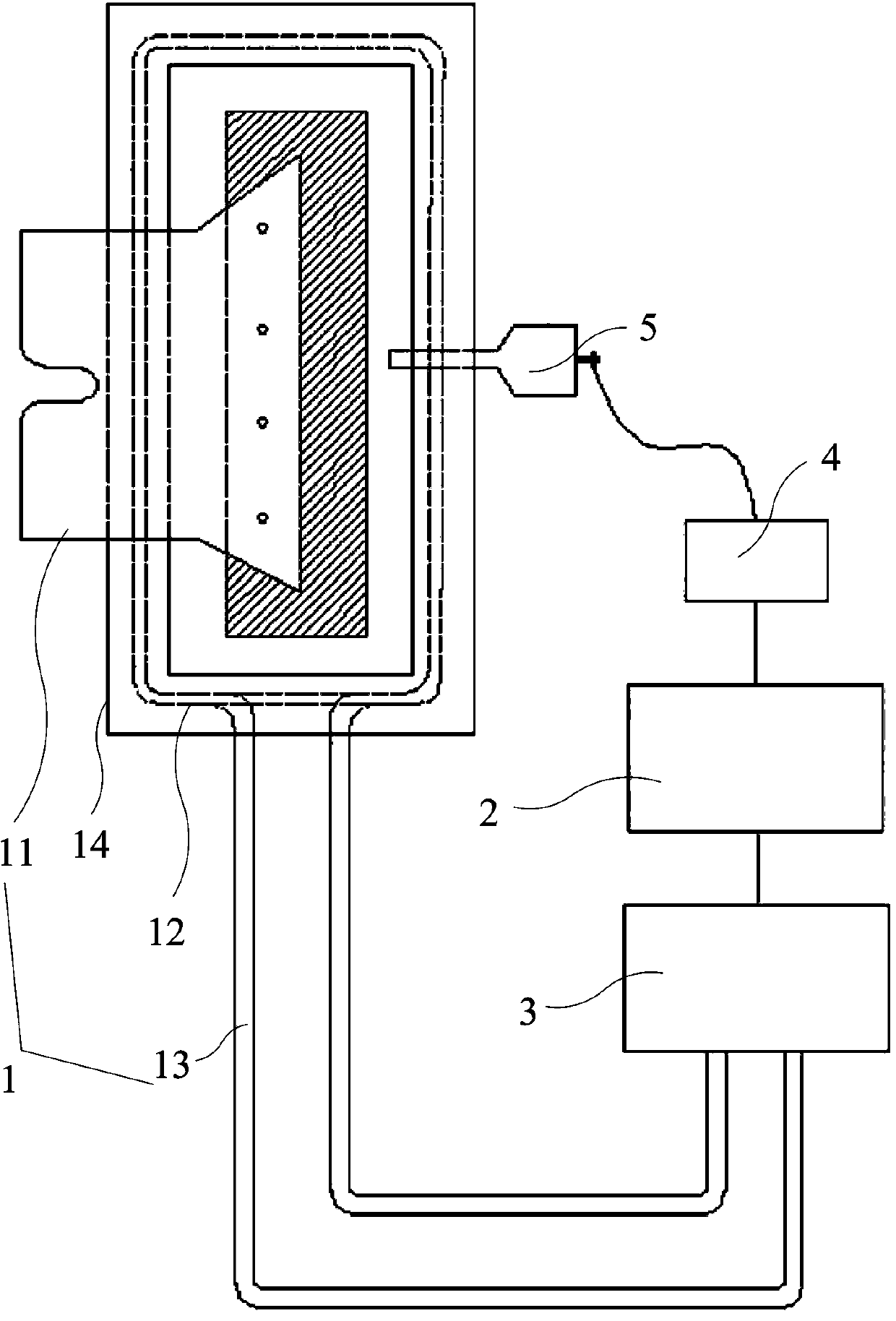

[0021] Such as figure 1 Shown is a preferred embodiment of a graphite anode heating device in rare earth molten salt electrolysis of the present invention, which includes an electromagnetic induction heating mechanism 1 and a host power supply 2; the electromagnetic induction heating mechanism 1 is electrically connected to the host power supply 2.

[0022] The above-mentioned heating device is used to heat the graphite anode. The heating method is that when in use, the graphite anode to be heated is first placed in the electromagnetic induction heating mechanism 1, and then the host power supply 2 is started, and the electromagnetic induction heating mechanism 1 converts the electric energy into electromagnetic Then the electromagnetic energy is converted into electric energy, and the electric energy is conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com