Self-moving multi-stage dust settling device for tunnel

A technology of dust suppression device and dust removal device, applied in safety devices, mining devices, dust prevention and other directions, can solve the problem of tunnel dust removal and tunnel construction cannot be carried out at the same time, achieve all-round rapid dust removal, realize intelligent control, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

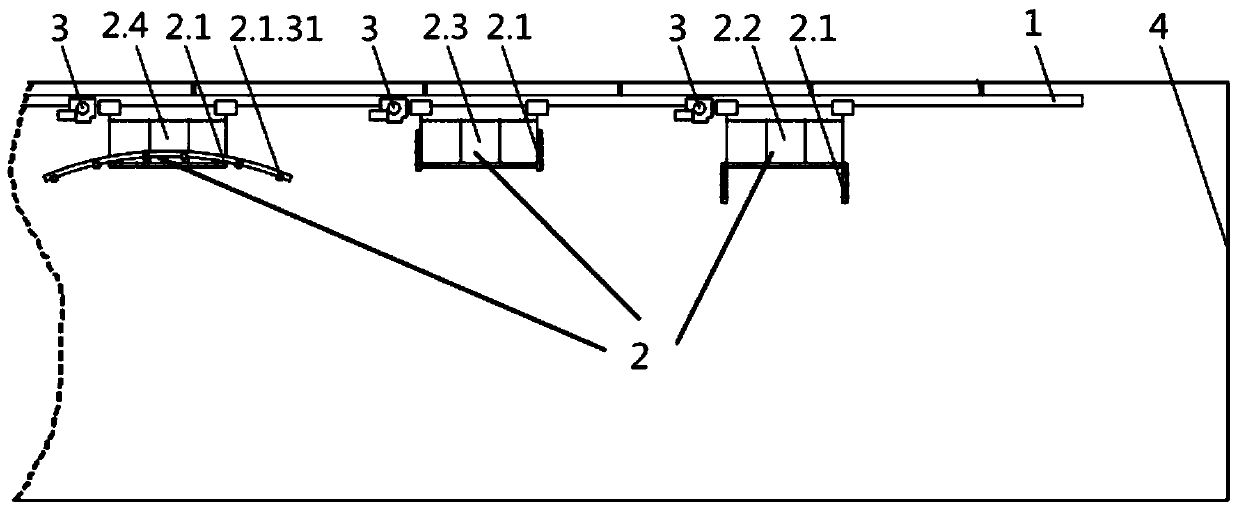

[0032] see Figure 1 to Figure 8 , a tunnel self-moving multi-stage dust suppression device, this embodiment is applied to tunnel dust removal.

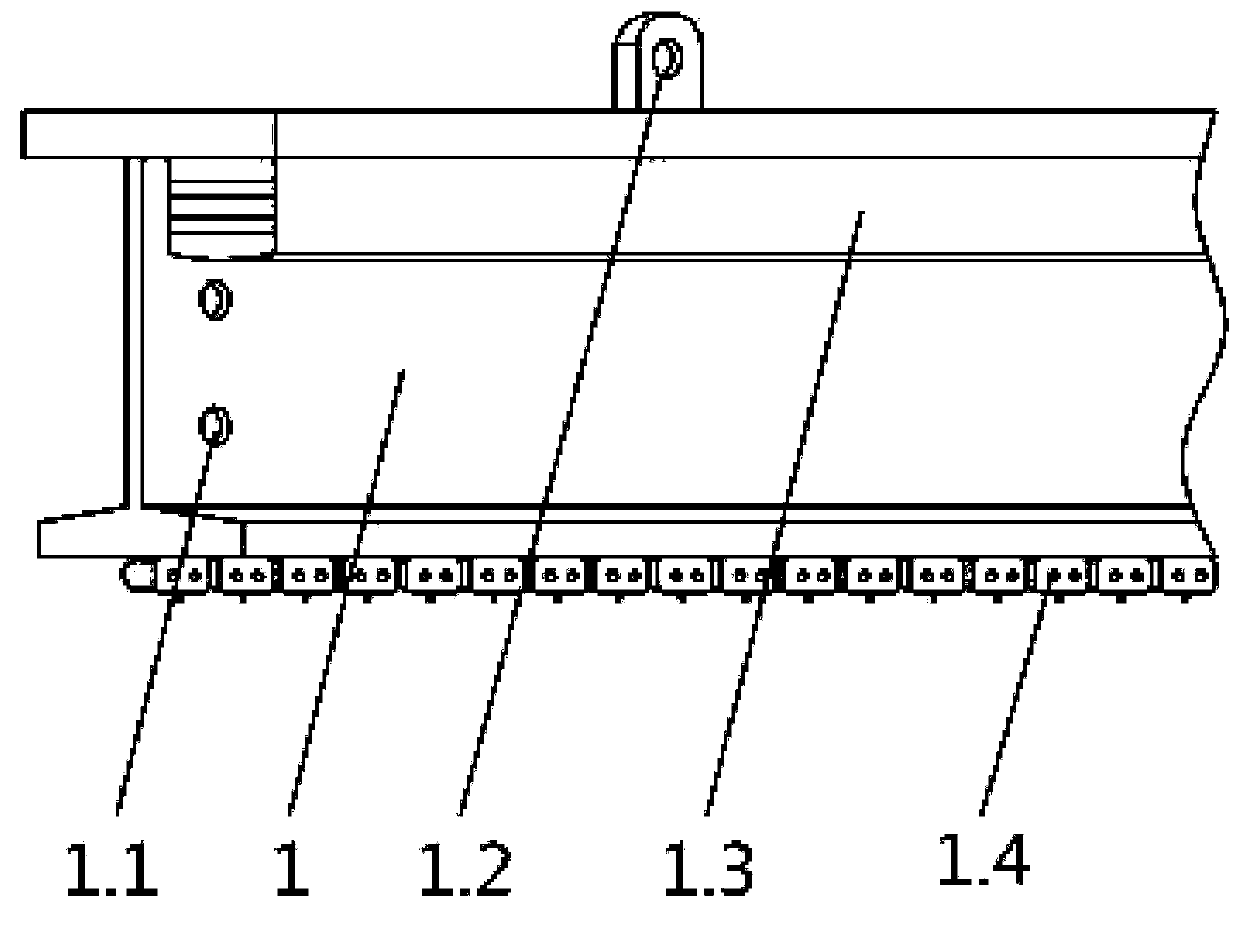

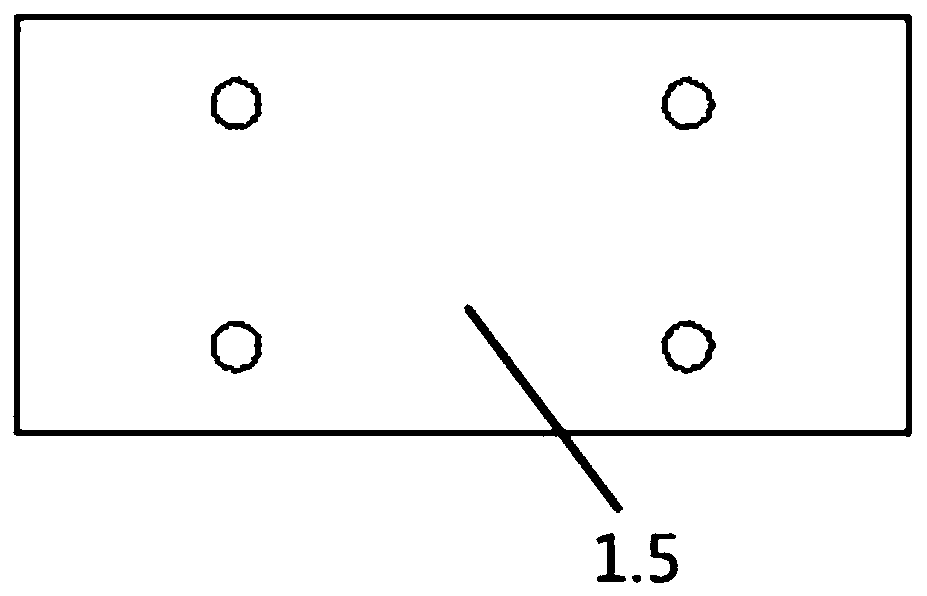

[0033] A self-moving multi-stage dust suppression device for a tunnel includes a rail 1 and a dust suppression device 2; the rail 1 is installed on the tunnel vault along the axial direction of the tunnel; Linear movement inside; the dust suppression device 2 is provided with a spray device 2.1, which is used to spray water mist to the tunnel to reduce dust in the tunnel.

[0034] see figure 1 , the dust suppression device 2 is fixedly connected with the monorail crane 3; the monorail crane 3 is installed on the track 1, drives the dust suppression device 2 to move on the track 1, and can realize the self-movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com