Gas turbine supercharger pressure regulation method and system

A technology for gas turbine and pressure regulation, which is applied in the direction of gas turbine devices, turbine/propellant fuel delivery systems, charging systems, etc., and can solve problems such as non-energy saving, high turbocharger power, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

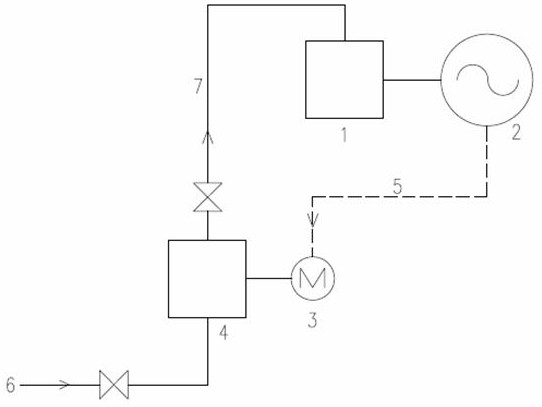

Method used

Image

Examples

Embodiment 1

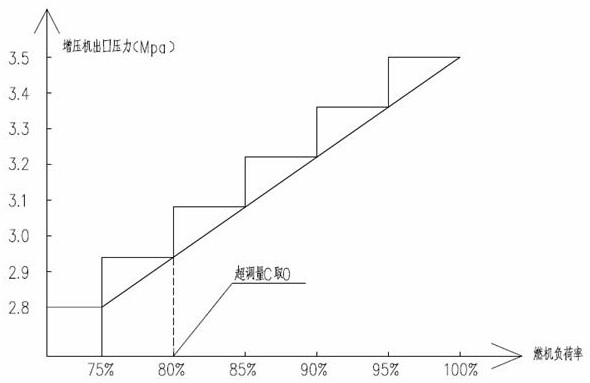

[0048] Such as figure 2 As shown, the overshoot c of each interval is 0.

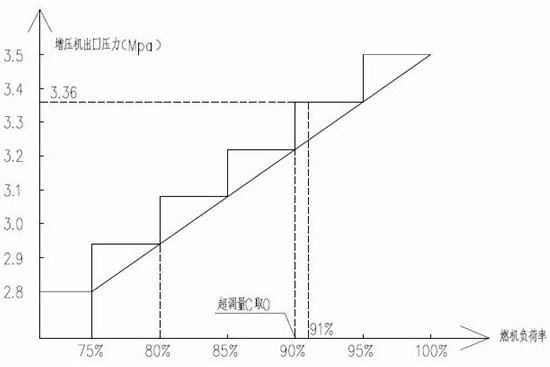

[0049] Such as image 3 As shown, when the actual load rate a of the gas turbine is 91%, the control device judges that it is in the range of 90%~95%, and then selects the upper limit of the range of 95% as a reference to calculate the outlet pressure value of the supercharger, according to image 3 Corresponding relationship of the curve, at this time, the outlet pressure P2 corresponding to the supercharger is 3.36Mpa.

Embodiment 2

[0051] When different actual load rates a are located in different intervals, the overshoots corresponding to different intervals are equal, assuming it is 2%; when the actual load rate a of the gas turbine is 91%, the control device judges that it is between 90% and 95% range, select the upper limit of the range of 95% and then 2% ahead, that is, select 97% as a reference to calculate the outlet pressure value of the supercharger. Such as Figure 4 The actual operating curve of the supercharger shown, according to Figure 4 According to the corresponding relationship of the middle curve, the outlet pressure P2 corresponding to the supercharger is 3.416Mpa at this time.

Embodiment 3

[0053] When different actual load rates a are located in different intervals, the overshoot amounts corresponding to different intervals are different.

[0054] The overshoot c is: c=a×K, the overshoot c has a linear relationship with the actual load rate a, the greater the actual load rate a, the greater the overshoot. The correction coefficient K is related to the pressure regulating station, unit characteristics and the actual gas pipeline layout of the gas turbine power plant. The specific value of the correction coefficient K can also be obtained by querying the empirical data table.

[0055] When the actual load rate a of the gas turbine is 91%, if K is 0.011 obtained from the table lookup, it is calculated as follows:

[0056] c=a*K=91%*0.011=1%

[0057] It can be obtained that the overshoot c is 1%, and the control device judges that 91% is in the range of 90%~95%, then select the upper limit of the range of 95% and then lead it by 1%, that is, select 96% as the refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com