A hydraulic system of an underwater multifunctional solid ballast dumping device

A hydraulic system and solid ballast technology, applied in the field of hydraulic systems, can solve problems such as poor stability and safety risks, and achieve the effect of convenient and quick pressure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

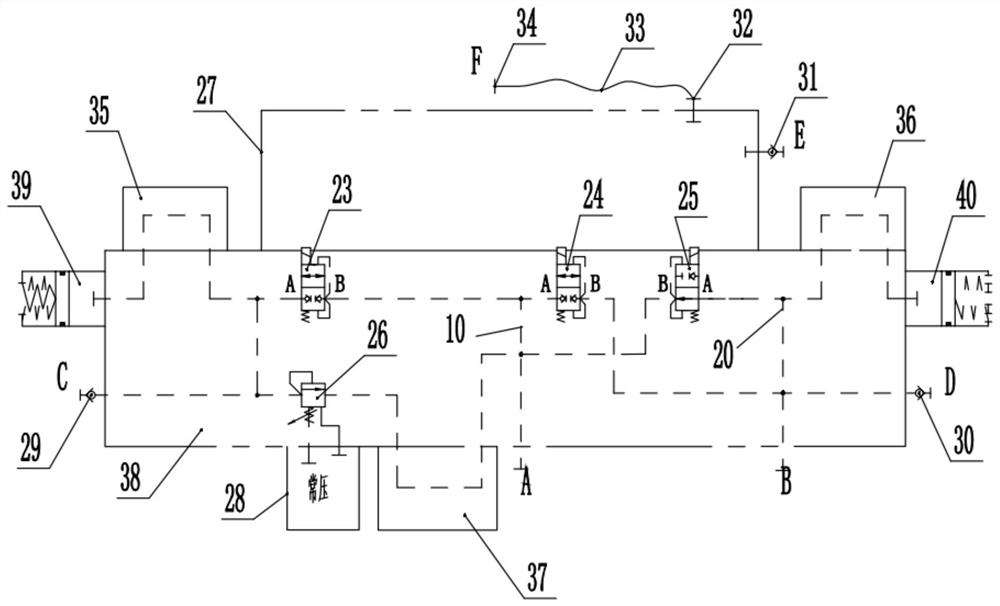

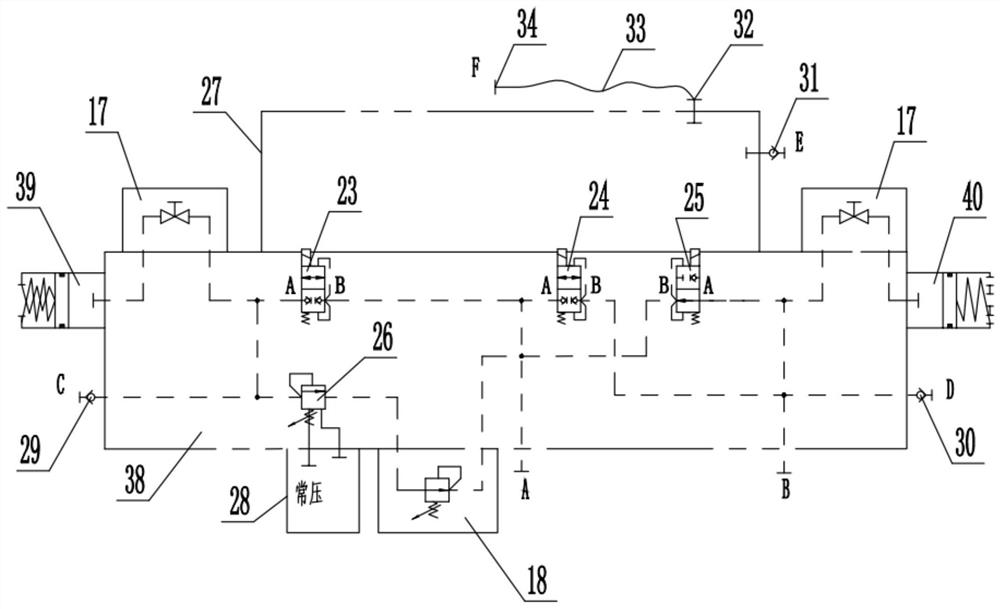

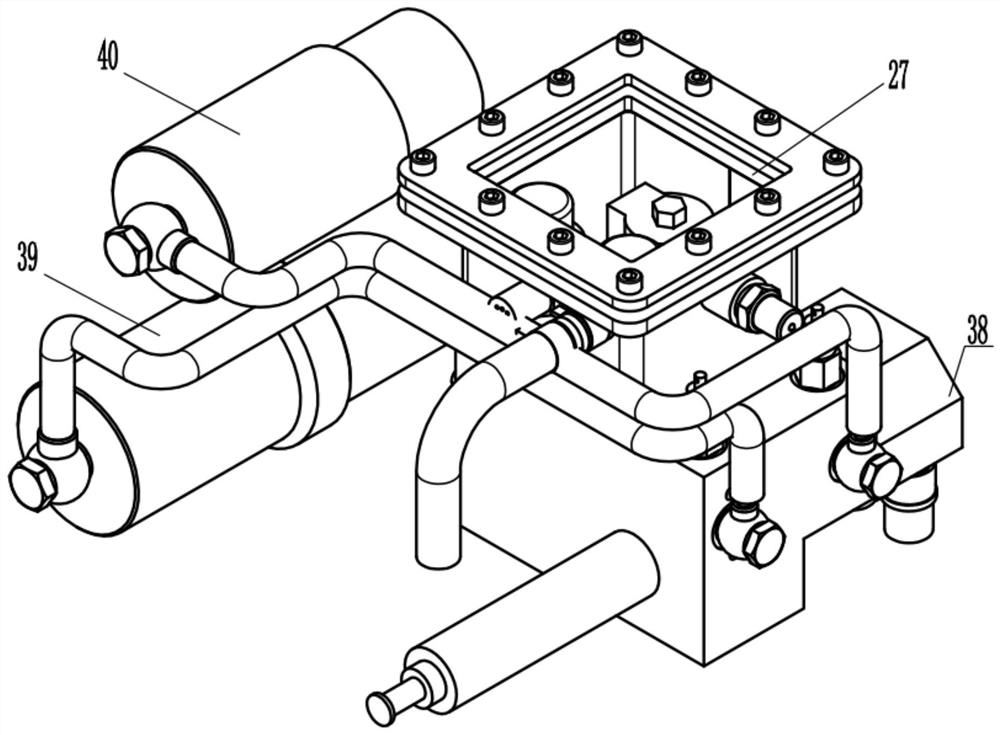

[0025] Such as Figure 1 to Figure 5 As shown, the hydraulic system of an underwater multifunctional solid ballast dumping device in this embodiment includes a first reversing valve 23, a one-way reversing valve 25, a high-pressure pressure compensator 39, a low-pressure pressure compensator 40, and a first reversing valve. An oil passage 10, the first reversing valve 23 of the second oil passage 20 communicates with the high-pressure pressure compensator 39, the one-way reversing valve 25 communicates with the low-pressure pressure compensator 40, and the first oil passage communicates with the high-pressure compensator 40 respectively. The first reversing valve 23 communicates with the rodless chamber 11 of the oil cylinder 1 , and the second oil passage 20 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com