Beam test piece forming device and forming method for asphalt mixture

A technology of asphalt mixture and forming device, which is applied in the field of road engineering asphalt mixture, can solve the problems of difficult forming of test pieces, stress concentration, and inability to vibrate and roll, and achieve the goals of improving accuracy, avoiding stress concentration, and improving forming efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

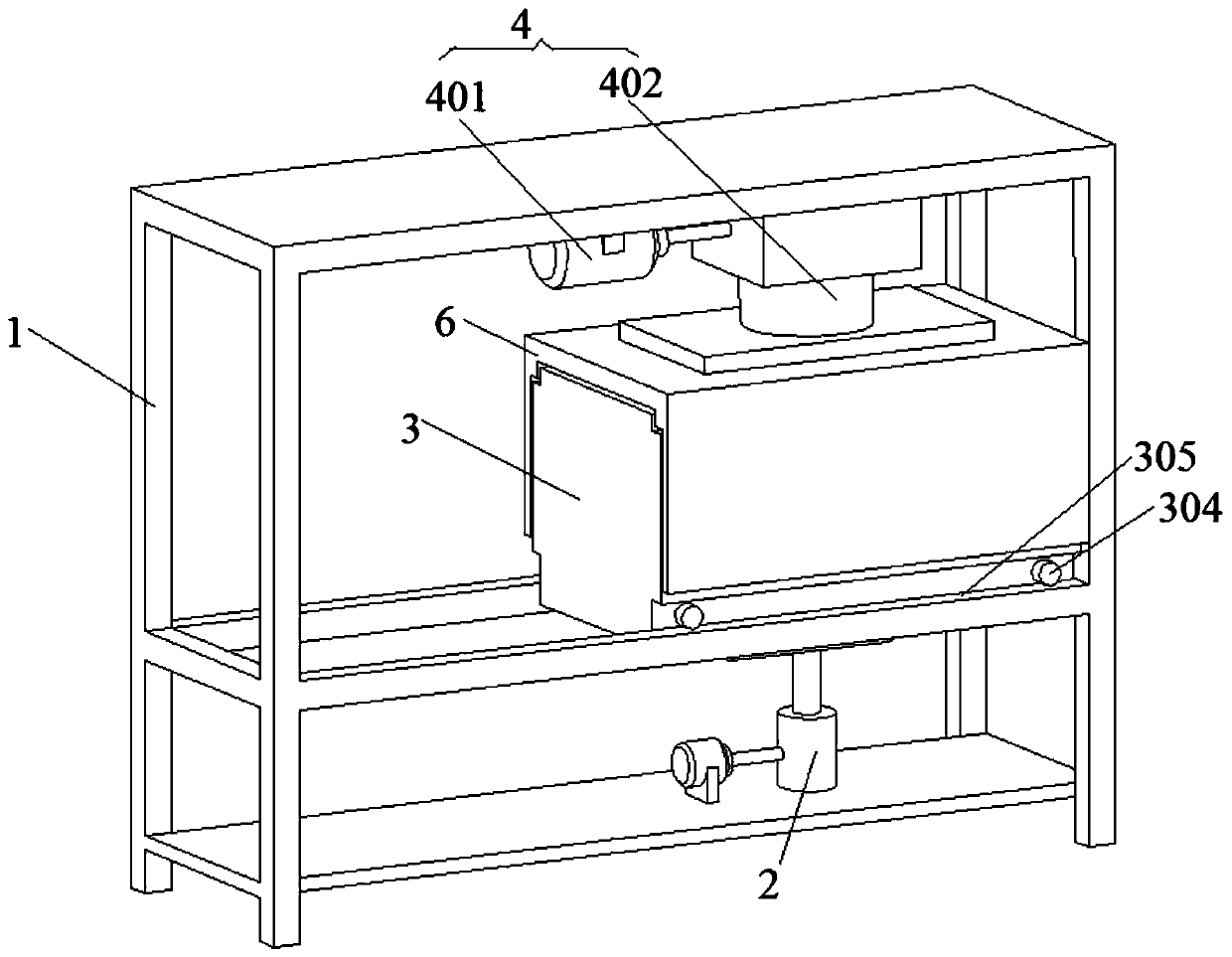

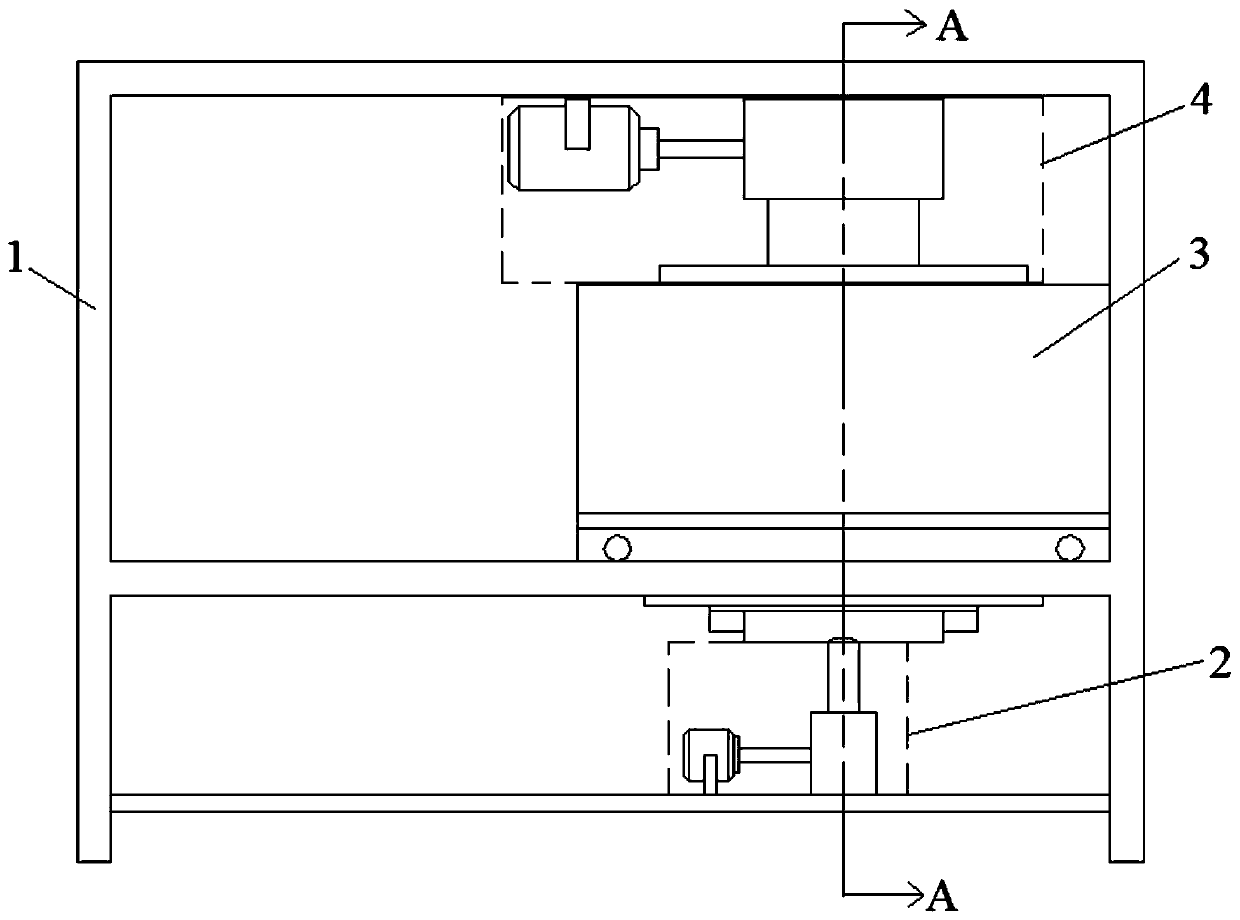

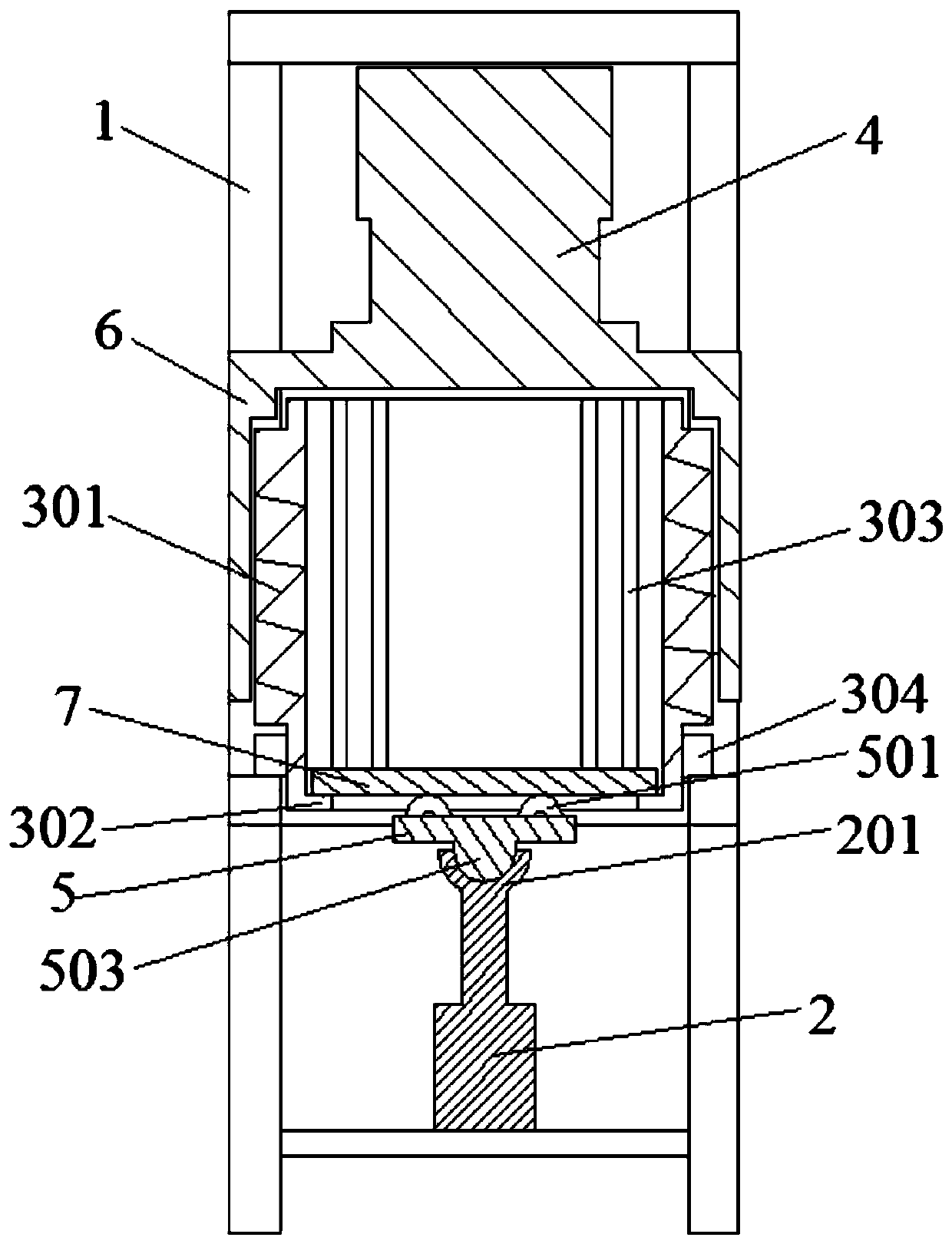

[0038] refer to Figure 1-7 , a kind of asphalt mixture beam specimen forming device of the present invention comprises: test support 1, and described test support 1 is provided with lifting unit 2, mold 3 and vibrating unit 4 from bottom to top; Wherein, described lifting The bottom of the unit 2 is fixed on the test support 1, and the upper end of the lifting unit 2 is horizontally provided with a support plate 5, and the support plate 5 has a certain thickness; There are multiple groups of wheel grooves on the front and rear sides respectively, and rolling wheels 501 are arranged in the grooves of the rollers 304. The upper surface of the support plate 5 is provided with a plurality of shaft grooves corresponding to each group of wheel grooves. A fixed shaft 502 is installed in the shaft groove, and the rolling wheel 501 is sleeved on the fixed shaft 502; the lower surface of the bearing plate 5 has a semicircular rotating shaft 503; the upper end of the lifting unit 2 has ...

Embodiment 2

[0058] A beam test piece forming method of asphalt mixture, comprising the following steps:

[0059] Step 1. According to the beam specimen width required by the test, install partitions in the corresponding vertical grooves, and erect the corresponding mobile baffles on the partitions to form corresponding charging chambers; Formed asphalt mixture;

[0060] Step 2: Turn on the heating unit to heat the material to the temperature required for the test; turn on the vibration unit to vibrate and compact the asphalt mixture to be formed in the mold to form a uniform material to be pressed;

[0061] Step 3: Turn on the lifting unit so that the bracket supports the support plate to move upwards. When the rolling wheel touches the moving baffle, under the action of vibration, the rolling wheel and the support plate start to rotate back and forth to crush the moving baffle. Press; when the material on the moving baffle is pressed against the mold cover, the beam specimen is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com