Current detection circuit and current detection method

A current detection circuit and current detection technology, applied in the direction of measuring current/voltage, only measuring current, measuring devices, etc., can solve the problem of too fast, a large amount of current flows through the dark current path, and the current supply time cannot provide enough current. To solve problems such as electrical protection, achieve simple and effective control methods, and reduce the risk of incorrect measurement or measurement component burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

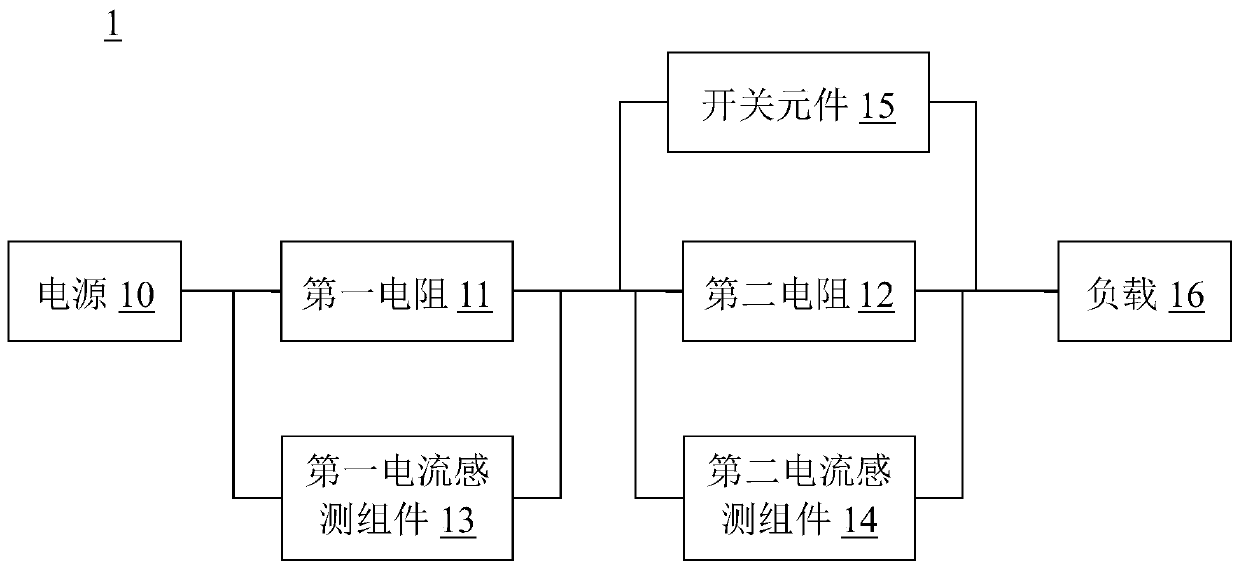

[0023] See figure 1 , figure 1 It is a schematic diagram of a current detection circuit according to an embodiment of the present invention. The current detection circuit 1 of the present invention is used to selectively measure a first current or a second current, and the current value of the first current is greater than the current value of the second current.

[0024] The current detection circuit 1 includes a power source 10 , a first resistor 11 , a second resistor 12 , a first current sensing component 13 , a second current sensing component 14 , a switching element 15 and a load 16 .

[0025] The first resistor 11 and the second resistor 12 are electrically connected in series between the power source 10 and the load 16 .

[0026] The first current sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com