A Laser Composite Additive Manufacturing Method Based on Pulsed Laser Controlled Melt Pool Flow

A pulse laser and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, metal material coating technology, etc., can solve the problem of not effectively reducing the workload of cladding layer surface processing, production efficiency, and difficulty in accurately controlling cladding Layer forging temperature, uneven cyclic heating and cooling process, etc., to achieve high-efficiency and high-quality continuous laser additive manufacturing, reduce the workload of subsequent processing, and improve the effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

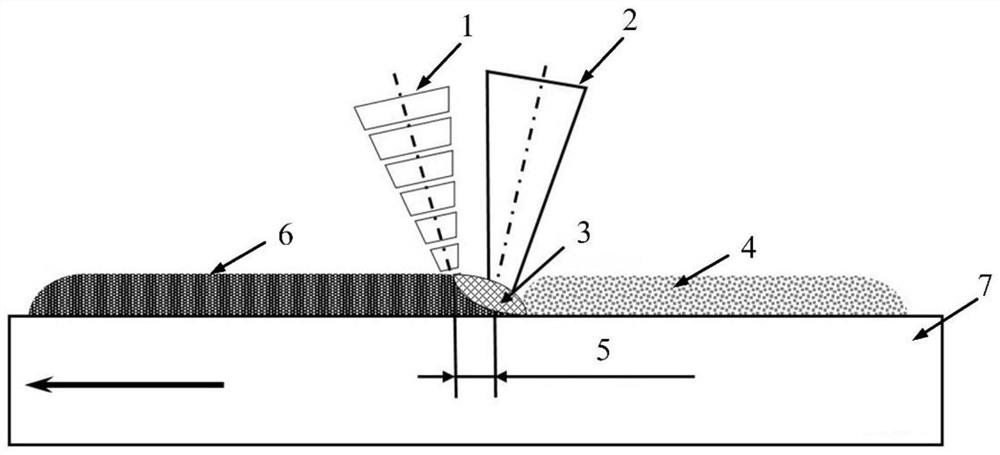

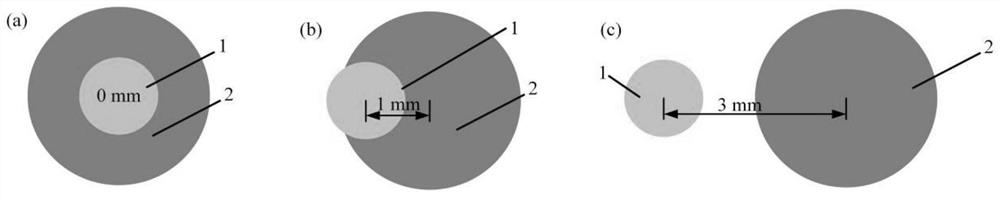

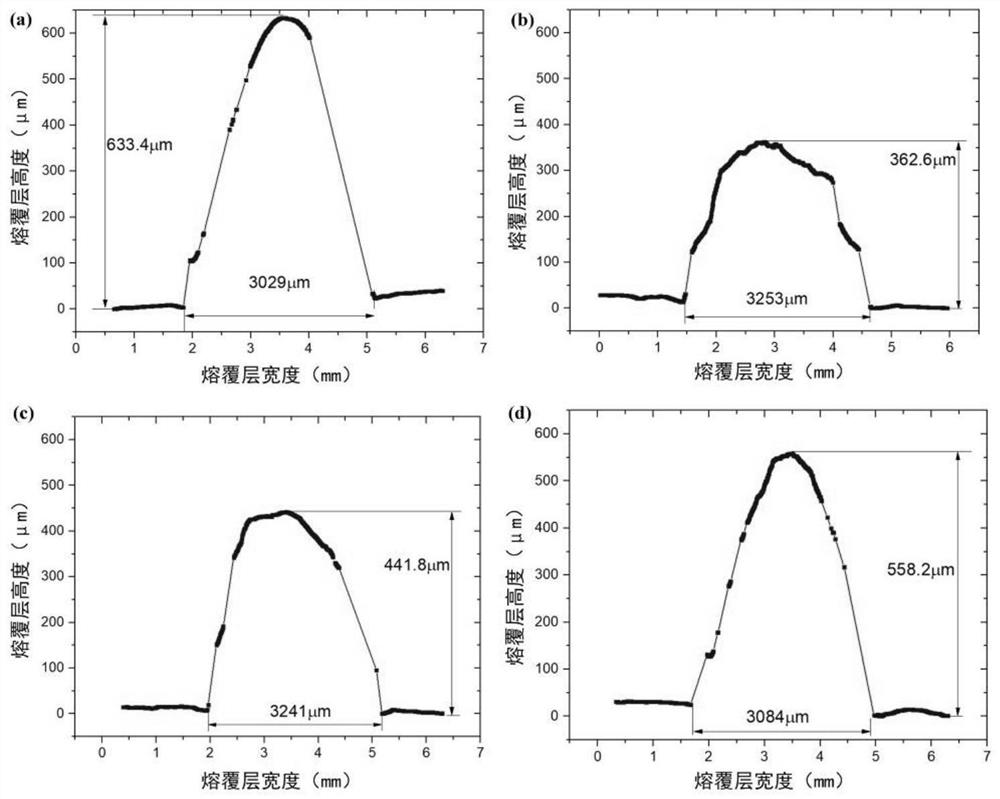

[0028] (1) Set process parameters. In this example, if figure 1 As shown, the energy of pulsed laser 1 is 2J, the power of continuous laser 2 is 1500W, the spot diameter of continuous laser beam 2 is 3mm, the spot diameter of pulsed laser beam is 1.3mm, and the scanning speed of pulsed laser beam 1 and continuous laser beam 2 is 4mm / s, the pulsed laser frequency is 5 Hz. The positional relationship between the pulsed laser 1 and continuous laser 2 spots is as follows figure 2 As shown in (a), the distance 5 between the two spots is 0 mm, and the pulsed laser beam completely acts on the molten pool area.

[0029] (2) Call the CNC workbench system to move the base material to the processing station to perform laser composite additive manufacturing. Turn on the continuous laser and the pulsed laser. The continuous laser beam acts on the surface of the substrate 7 to be processed after being collimated and focused, so that the surface of the substrate and the preset alloy po...

Embodiment 2

[0033] In this embodiment, the distance between the two light spots is 1mm, and the pulsed laser beam acts partly on the molten pool area, and partly acts on the solidification area, such as figure 2 (b) shown. The remaining implementation process is consistent with embodiment 1.

[0034] From image 3 It can be seen from the 2D profile of the cladding layer section in (c) that when the pulsed laser beam partially acts on the molten pool, the thickness of the cladding layer after the impact of the pulsed laser beam is 441.8 μm, and the thickness of the cladding layer is reduced by about 30.2%. The residual stress of the cladding layer impacted by the pulsed laser beam has no obvious change from that of the cladding layer without the action of the pulsed laser beam. This is because part of the pulsed laser beam acting on the molten pool area can reduce the residual stress of the cladding layer, and part of the pulsed laser beam acting on the solidification area causes plasti...

Embodiment 3

[0036] In the present embodiment, the distance between the two light spots is 3 mm, and the pulsed laser beam is completely applied to the coagulation area such as figure 2 (c) shown. The remaining implementation process is consistent with embodiment 1.

[0037] From image 3 It can be seen from the 2D profile of the cladding layer section in (d) that when the pulsed laser beam fully acts on the solidification area, the thickness of the cladding layer is 558.2 μm, and the thickness of the cladding layer is reduced by about 11.8%. The residual stress of the cladding layer is -381MPa, and the residual stress of the cladding layer increases by about 14.7%. Additionally, from Figure 7 It can be seen from the figure that the microstructure of the solidification region acted on by the pulsed laser beam is similar to the microstructure characteristic when the pulsed laser beam acts on the solidified region in Example 2, presenting fine equiaxed crystals. It shows that the pulse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com