Crimping type IGBT device structure optimization design method

A technology for optimizing design and device structure, applied in computer-aided design, design optimization/simulation, instrumentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Below in conjunction with embodiment, the present invention is described further, but does not constitute any restriction to the present invention, any limited number of modifications done in the scope of claims of the present invention is still within the scope of claims of the present invention.

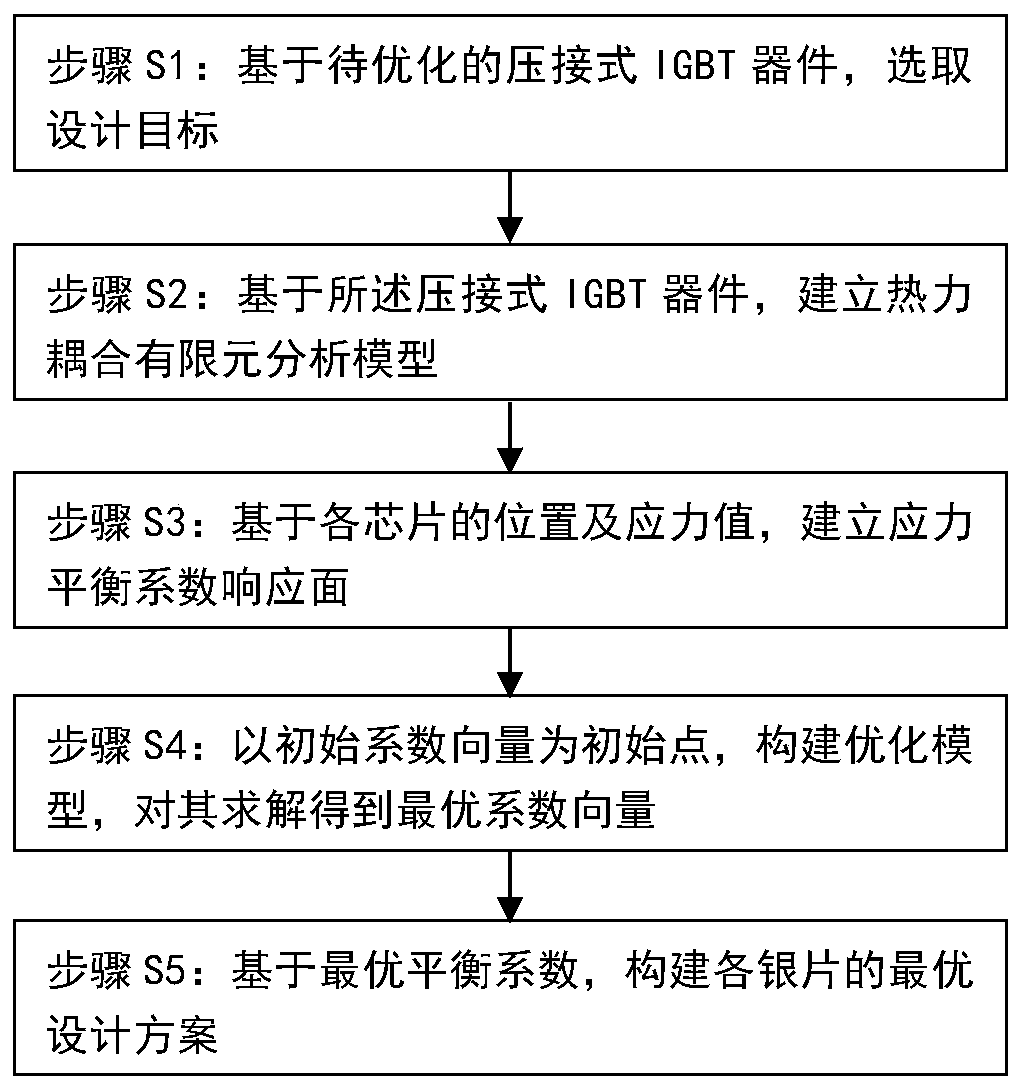

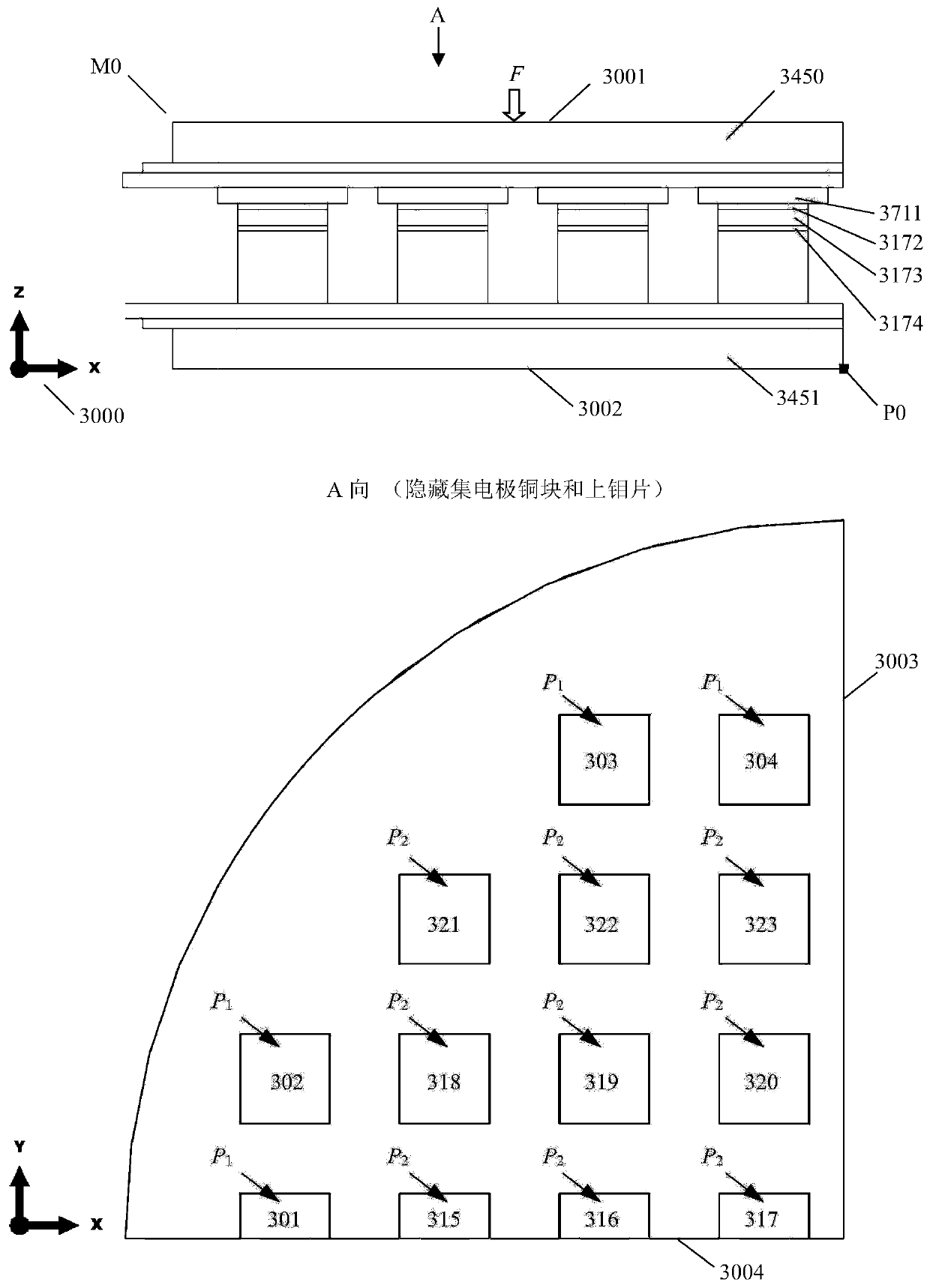

[0080] Such as figure 1 — Figure 4 As shown, the present invention provides a method for optimizing the design of a crimped IGBT device structure, the method comprising the following processing steps:

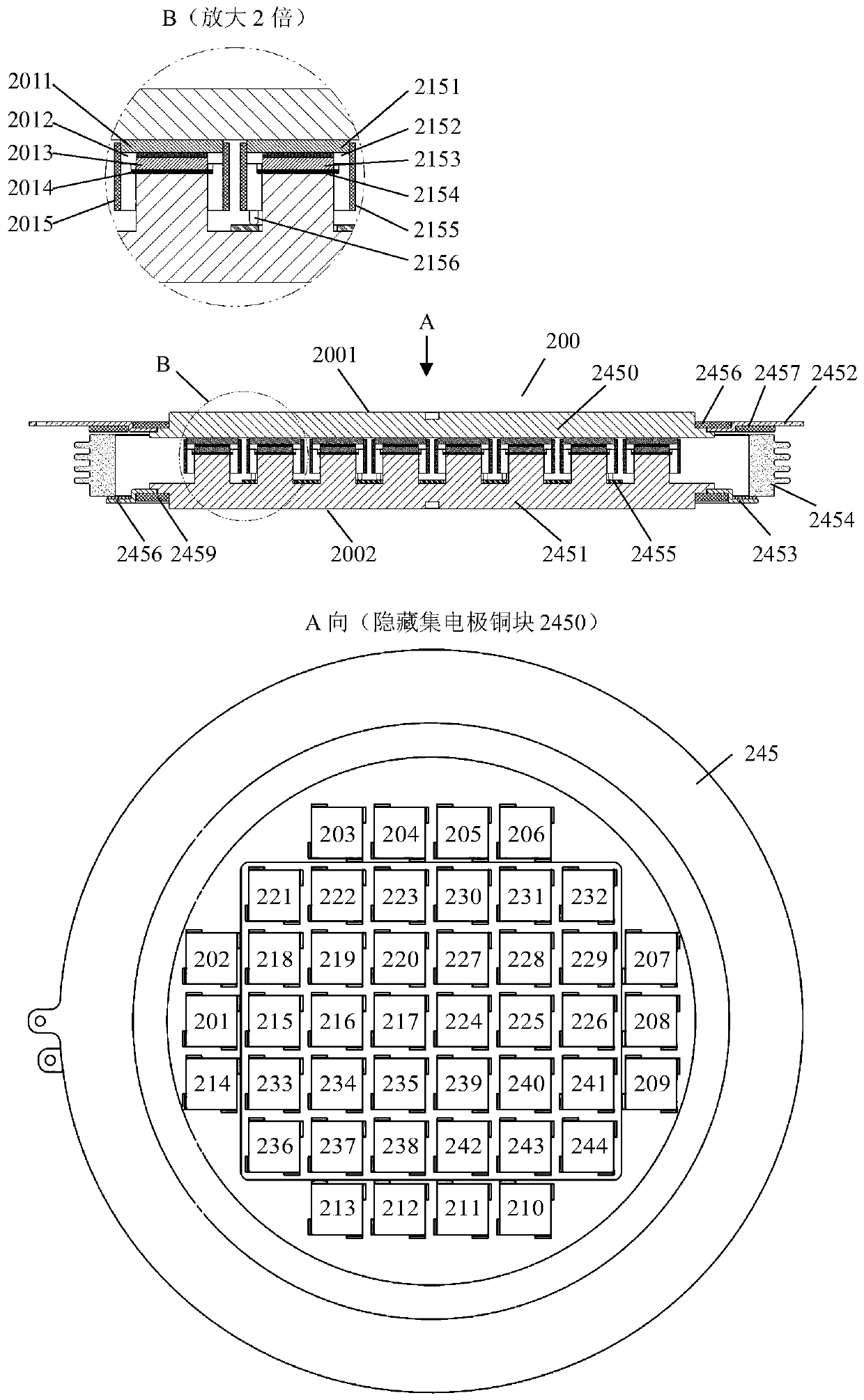

[0081] Step S1: Based on the press-connect IGBT device to be optimized, select a design target. Such as figure 2 As shown, the crimp-type IGBT device 200 in this embodiment is composed of a housing module 245 and 44 first sub-modules (201-244). The casing module 245 is composed of a collector copper block 2450 , an emitter copper block 2451 , a collector flange 2452 , an emitter flange 2453 , a tube shell 2454 , a circuit board 2455 , and insulating pads 2456-2459. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com