A structure optimization design method of compression piezoelectric accelerometer

A piezoelectric accelerometer and optimization design technology, applied in design optimization/simulation, genetic rules, geometric CAD, etc., can solve the problems of key performance failure of accelerometer, unbearable design cost, engineering application obstacles, etc., to achieve easy implementation and The effect of popularization, easy operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with embodiment, the present invention is further described, but does not constitute any limitation to the present invention, and any limited modification done in the scope of the claims of the present invention is still within the scope of the claims of the present invention.

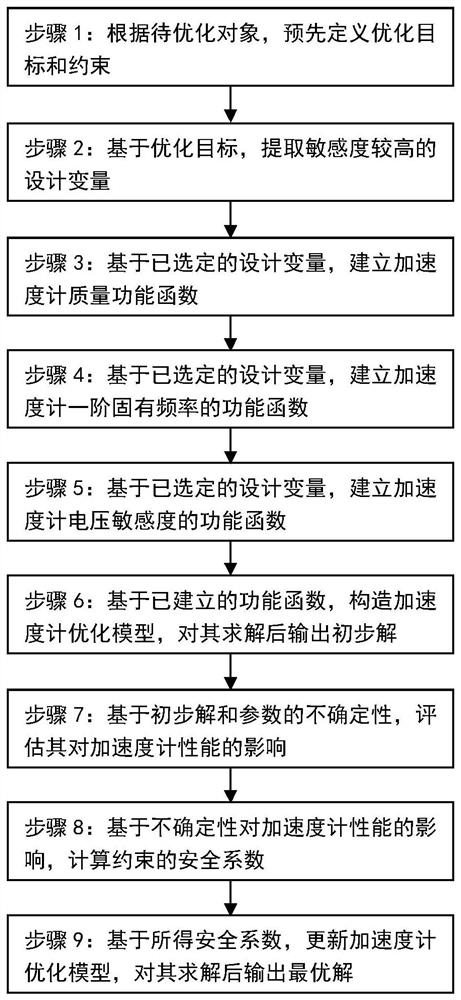

[0053] like figure 1 — image 3 As shown, the present invention provides a structure optimization design method of a compression piezoelectric accelerometer, and the method includes the following processing steps:

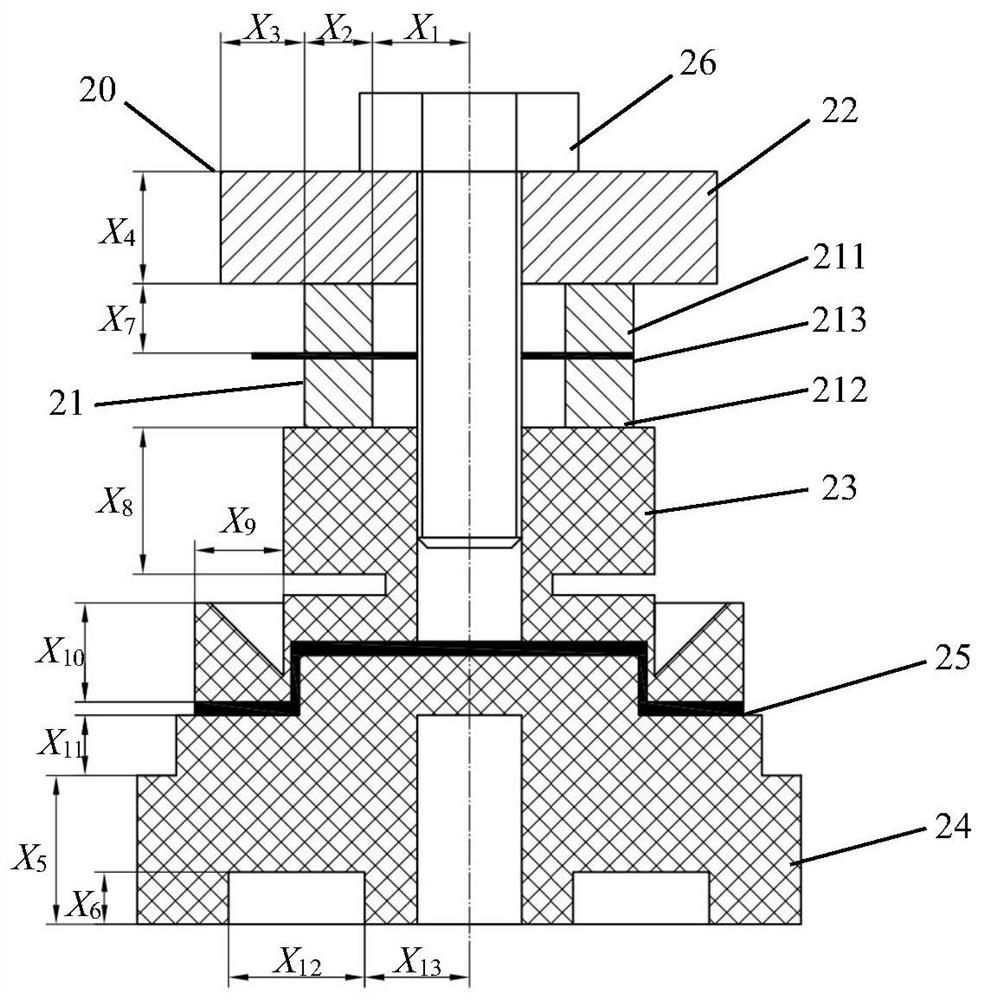

[0054] Step 1: According to the accelerometer to be optimized, the optimization objectives and constraints are pre-defined. like figure 2 As shown, the compression piezoelectric accelerometer 20 to be optimized is composed of a piezoelectric element 21, a mass element 22, a tailstock 23, a base 24, an insulating pad 25, and a bolt 26; the piezoelectric element 21 includes two annular upper , the lower piezoelectric block (211, 212) and an electrode plate 213;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com