A method for detecting the initial position of a permanent magnet motor rotor

A rotor initial position, rotor position technology, applied in the direction of motor, control generator, motor generator control, etc., can solve the problems of increasing system complexity and implementation difficulty, to avoid repeated trial and error process, improve detection speed, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

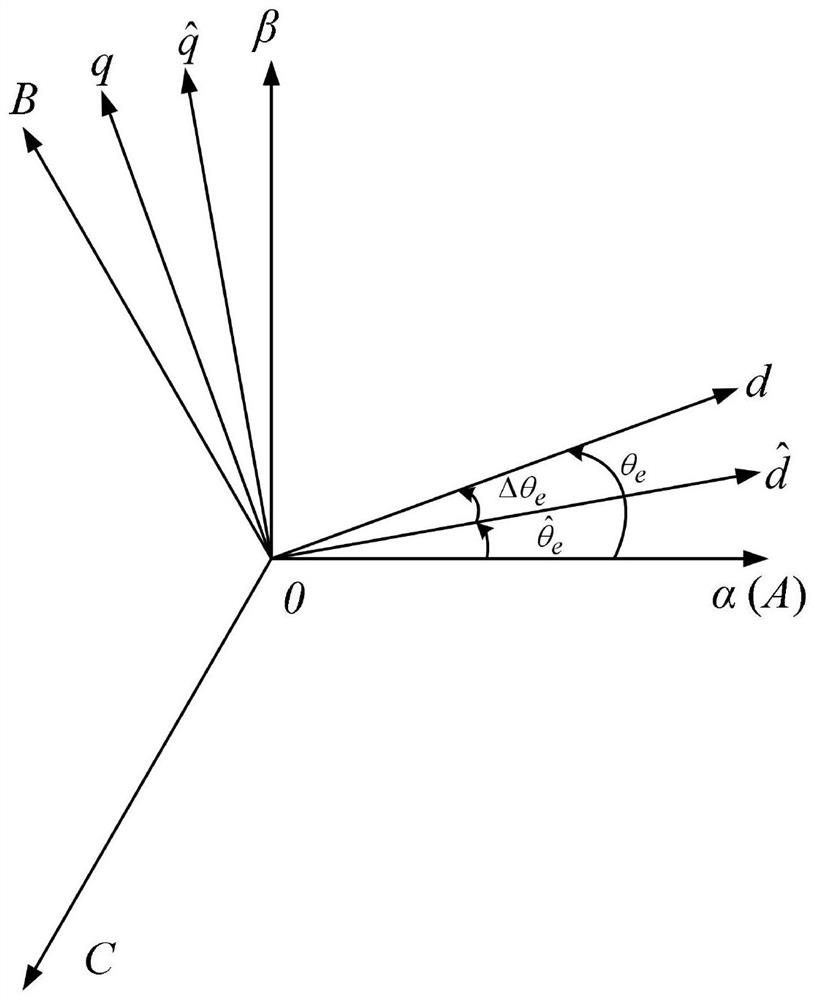

[0037] like figure 1 As shown, establish a two-phase stationary coordinate system α-β, an actual rotor synchronous rotating coordinate system d-q and an estimated rotor synchronous rotating coordinate system where the angle between the d axis and the α axis is the actual rotor position θ e , The angle between the axis and the alpha axis is the estimated rotor position and

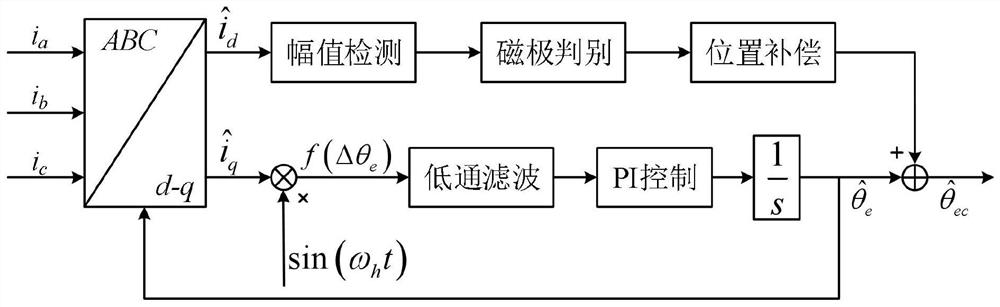

[0038] like figure 2 As shown, the method for detecting the initial position of the permanent magnet motor rotor of the present invention includes the following steps:

[0039] Step A) Initial estimation of rotor position: towards the estimated The shaft injects a high-frequency carrier voltage, which is acquired by The carrier current of the shaft and closed-loop control to achieve the initial estimation of the rotor position;

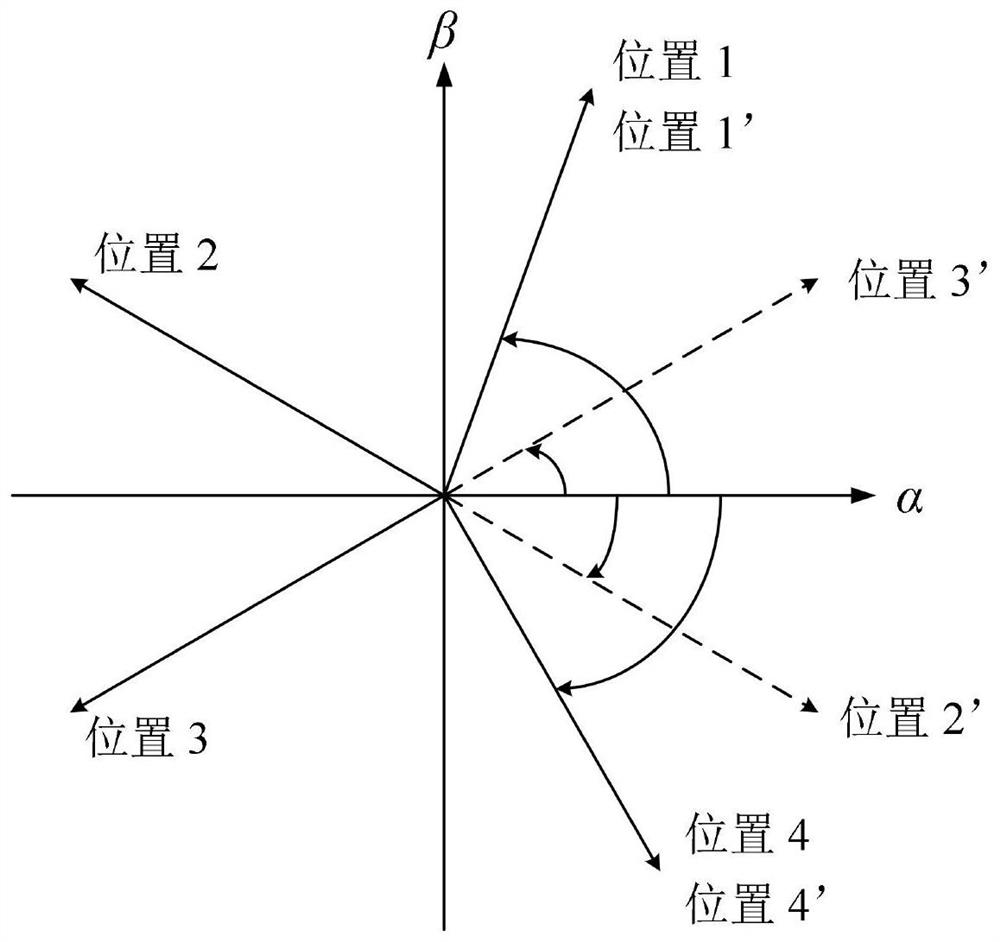

[0040] Step B) Disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com