Product surface defect detection method, electronic equipment and readable storage medium

A defect detection and product technology, applied in neural learning methods, image data processing, image enhancement, etc., can solve problems such as low robustness and technical scalability, long training time, low proportion of defective products, etc., to reduce errors The probability of being judged as a good product and the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

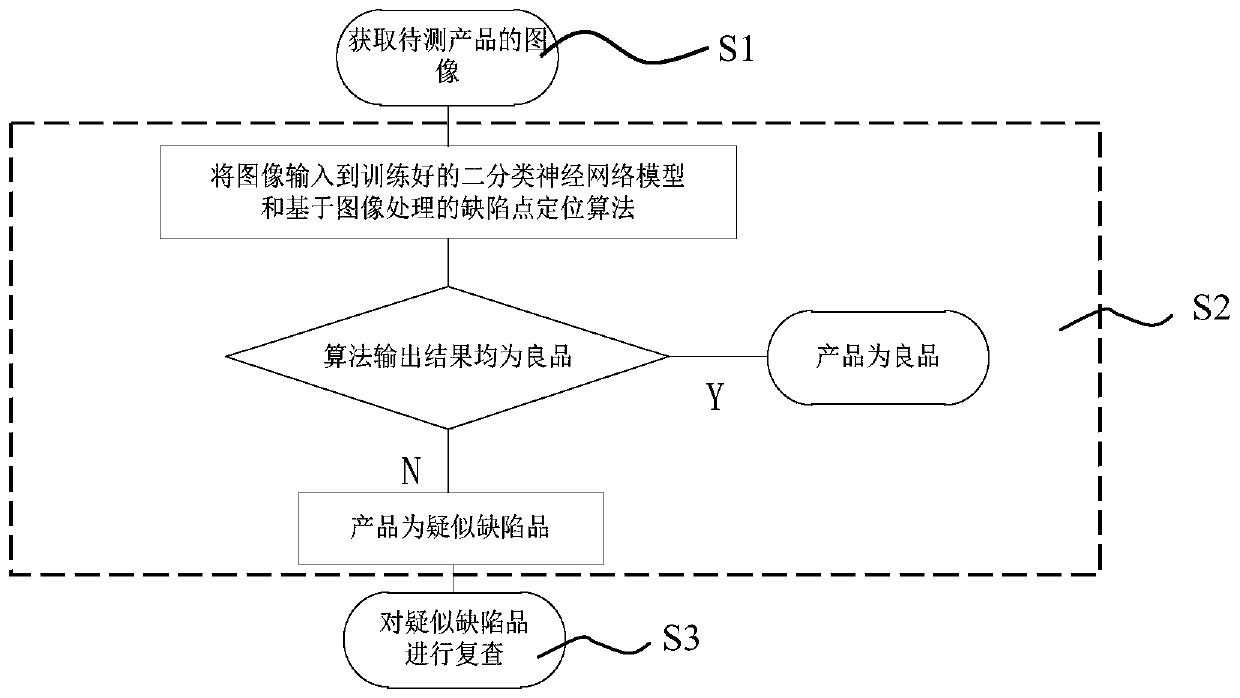

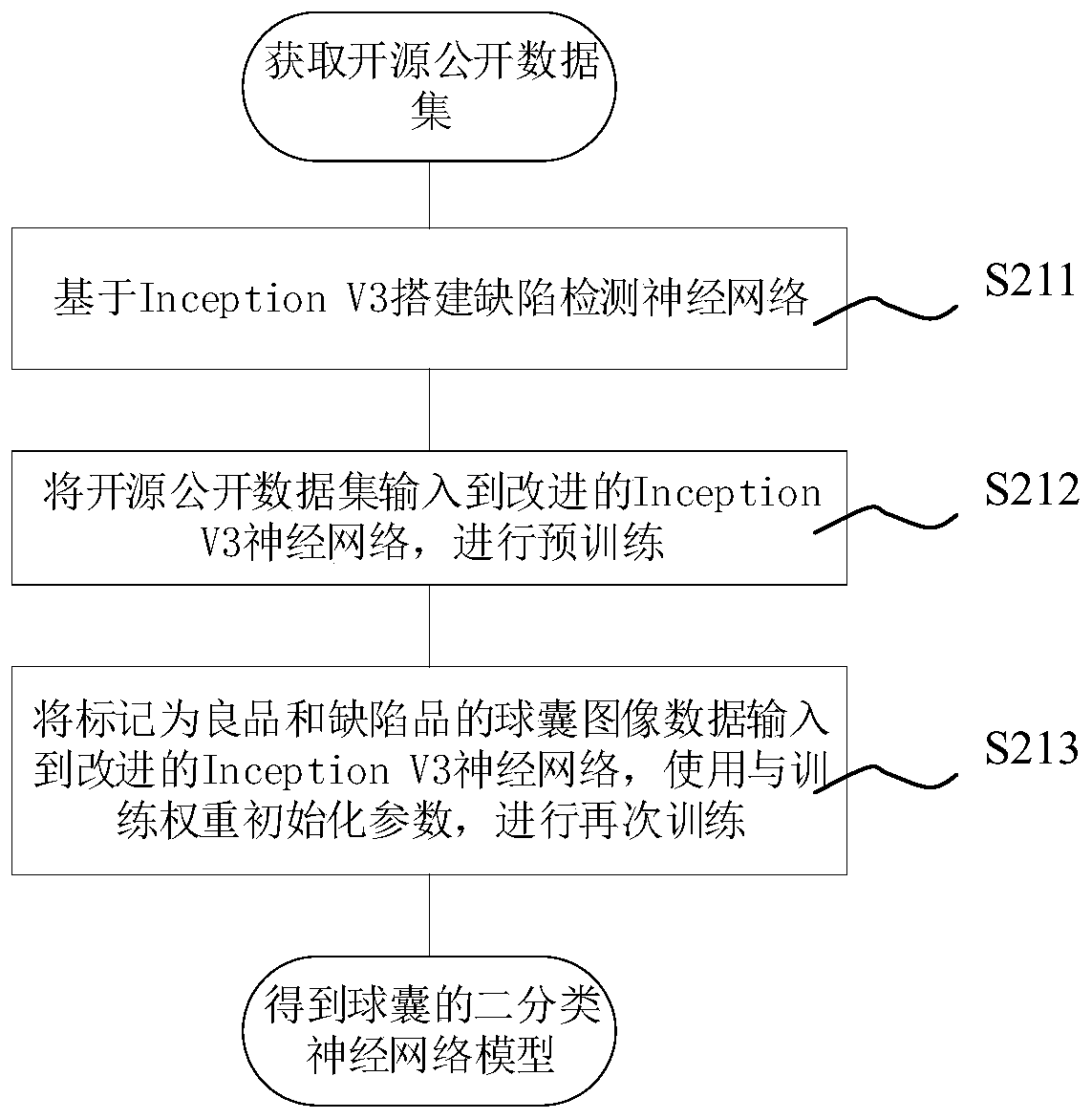

[0052] See figure 1 , the steps of the surface defect detection method of the balloon product provided in this embodiment are as follows:

[0053] Step S1: Use an industrial camera to take pictures of the balloon to obtain an image of the balloon to be tested;

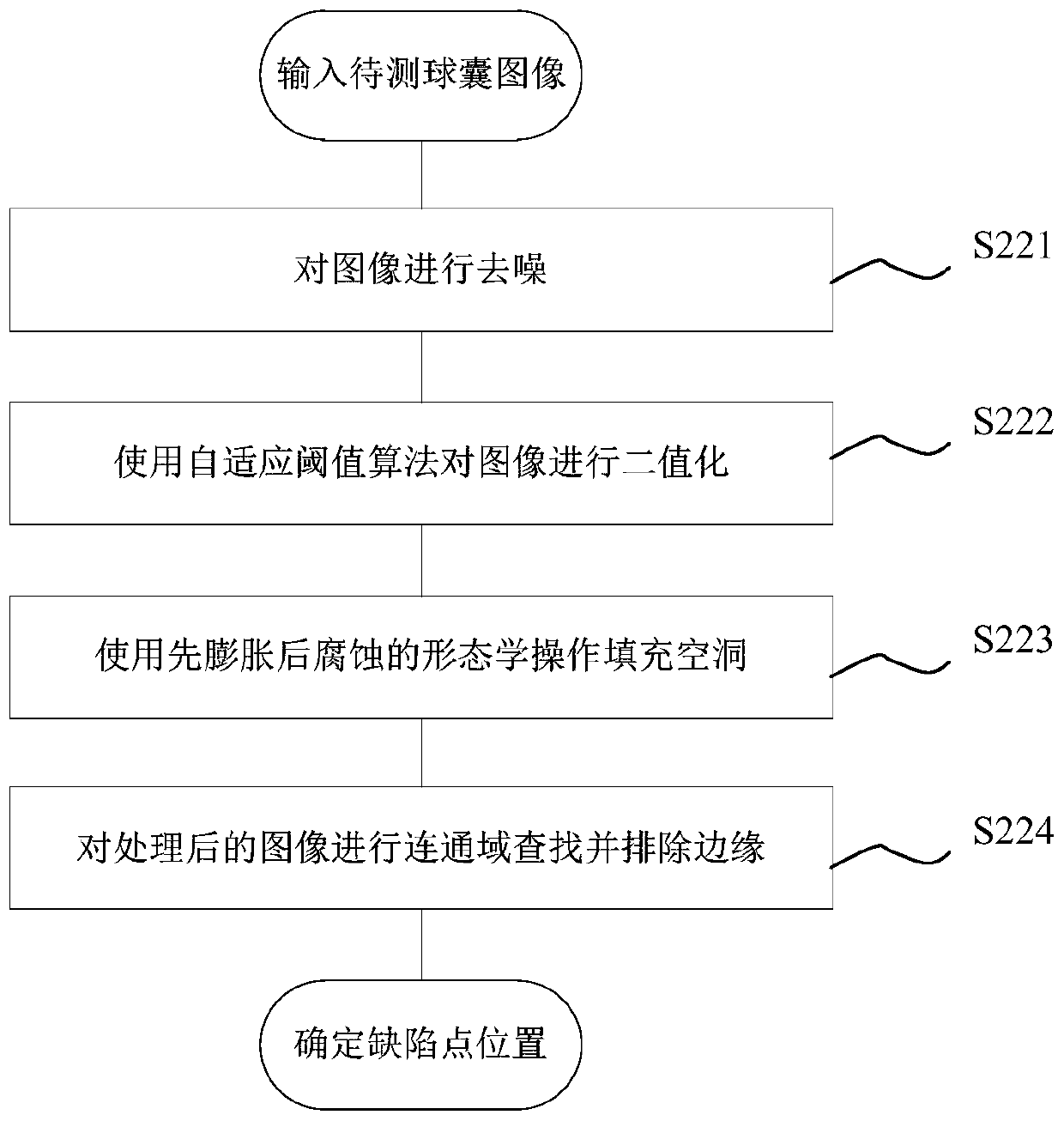

[0054] Step S2: Input the image of the balloon to be tested into the trained binary classification neural network model and the defect point location algorithm based on image processing for parallel operation, and the defect point location algorithm uses the first preset area threshold to determine Whether the balloon to be tested is a good product; if both the trained binary classification neural network model and the defect point location algorithm based on image processing are identified as a good product, then it is determined that the balloon to be tested is a good product, otherwise it is determined that the balloon to be tested is a good product. The balloon to be tested is a suspected defective product for re-...

Embodiment 2

[0103] Step S1 and step S2 of this embodiment are all the same as in embodiment 1, the difference is the review step in step S3, please refer to Figure 5 , the review link of this embodiment does not include step S31 and step S41 of embodiment 1, but includes the following step S42:

[0104] Step S42: If the defect point positioning algorithm based on image processing in step S2 determines that the product balloon to be tested is a defective product, then output the position coordinates of the suspected defect point, crop the image of the suspected defect point according to the position coordinates of the suspected defect point, and calculate The area of the cropped suspected defect point image, if the area is smaller than the third preset area threshold, the target is considered to be extremely small, and the product balloon to be tested is determined to be a good product; otherwise, the product balloon to be tested is determined to be a suspected defective product. Step S...

Embodiment 3

[0107] This embodiment provides an electronic device, including a processor and a memory, where a computer program is stored on the memory, and when the computer program is executed by the processor, the detection method of Embodiment 1 or / and Embodiment 2 is implemented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com