OLED display substrate, manufacturing method thereof and display device

A technology of display substrate and manufacturing method, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low amount of information, low PPI pixel density, poor user experience, etc., and achieve the effect of improving pixel density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

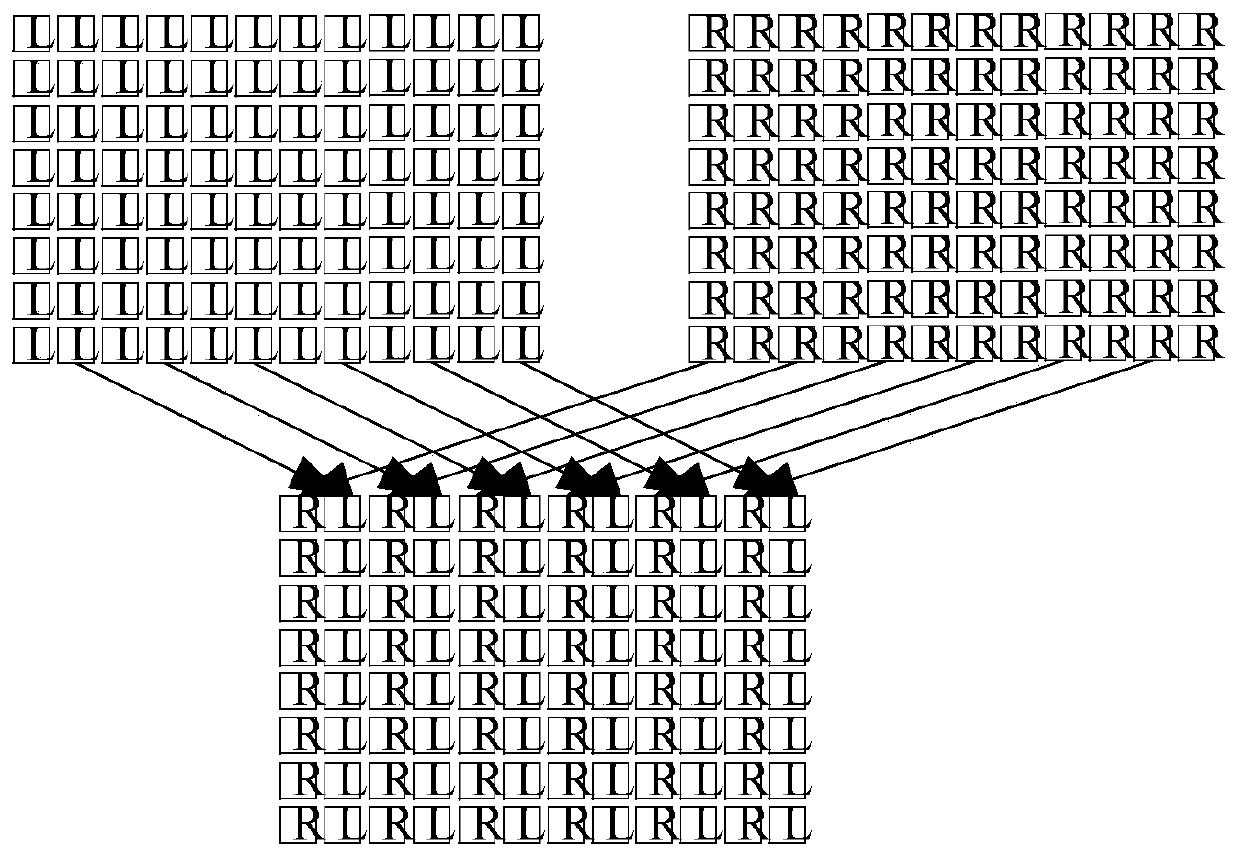

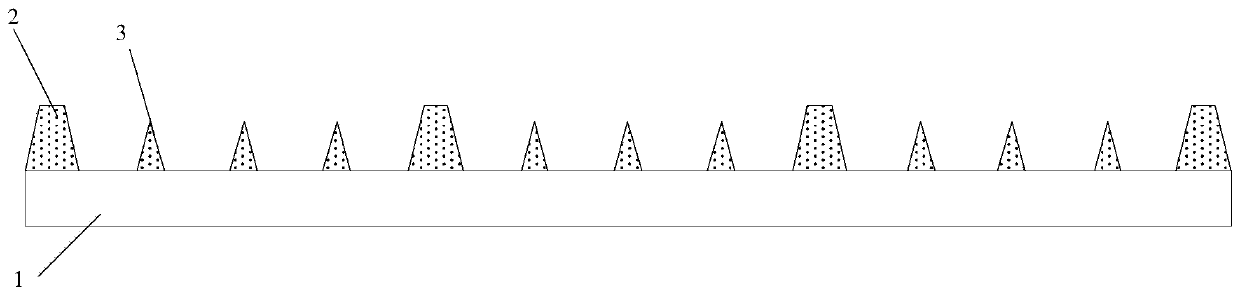

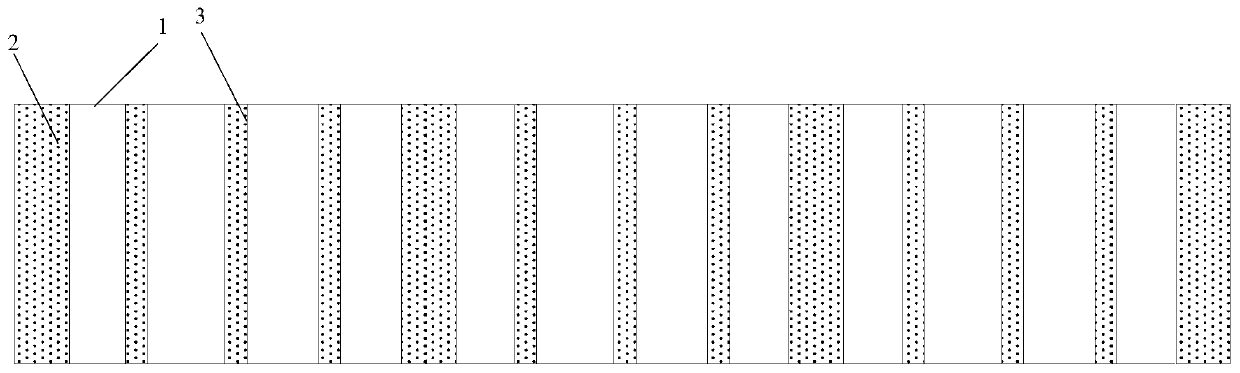

[0040] Glasses-free 3D display technology mainly includes holographic 3D display technology, autostereoscopic 3D display technology, etc. Among them, autostereoscopic 3D display technology has been considered as the naked-eye 3D display technology that may be commercialized the fastest because it can obtain dynamic, colorful and three-dimensional display effects with a large viewing angle. Autostereoscopic 3D display technology can be roughly divided into two categories: one is naked-eye 3D display technology based on geometric optics, such as the relatively mature cylindrical lens array technology, parallax barrier technology, and microlens array technology. This type of technology is mainly based on the principles of straight line pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Bottom corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com