Micro motor protection device

A technology of micro-motors and protection devices, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as easy to be knocked, small size, small capacity, damage to motor parts, etc., to achieve sufficient protection, easy and fast installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

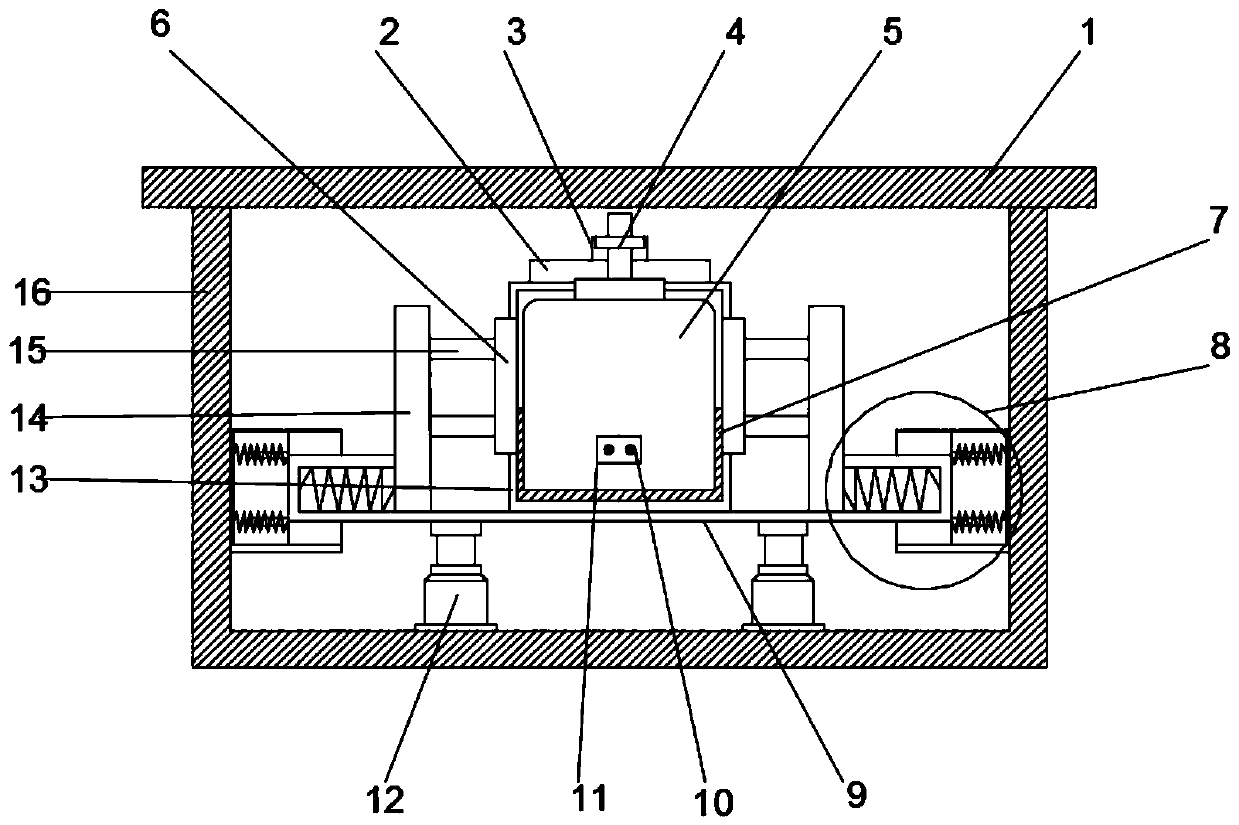

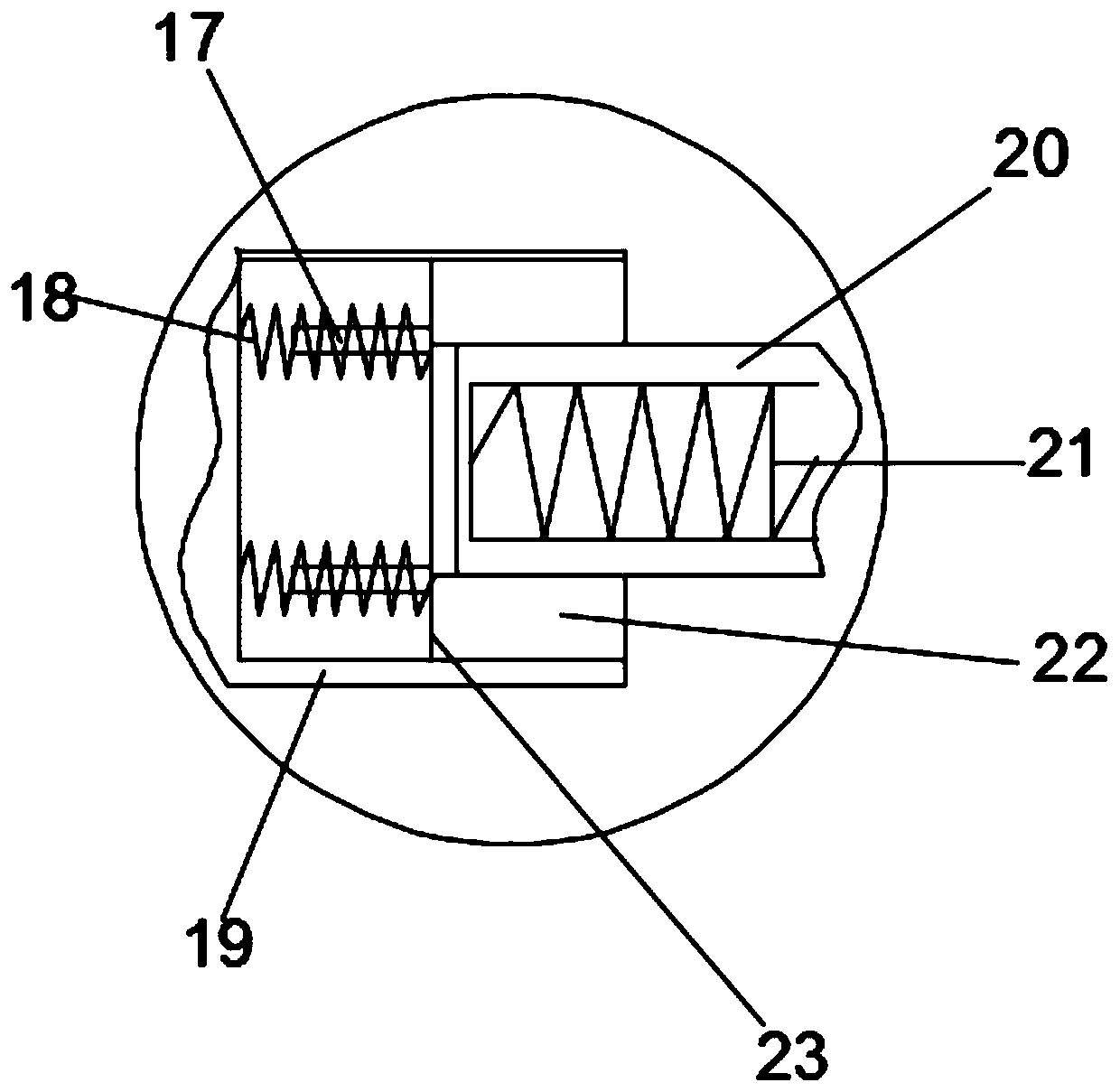

[0020] see Figure 1-3 , a miniature motor protective device, including a protective cover 1 and a protective box 16, the protective cover 1 and the protective box 16 are connected by bolts, the bottom of the protective box 16 is fixedly installed with a buffer hydraulic rod 12, the buffer hydraulic rod 12 is about There is one each, the tops of the two buffer hydraulic rods 12 are connected to the fixed plate 9, the two ends of the fixed plate 9 are respectively provided with a clamping plate 14, and the two ends of the fixed plate 9 and the side wall of the protective box 16 are installed with buffer devices 8. A buffer plate 19 is connected to the bottom of the buffer device 8 and the side wall of the protective box 16. The two buffer plates 19 have buffer grooves 22 on one side close to each other. The buffer groove 22 is slidably connected to the moving plate 23. A plurality of limit blocks 17 are welded to the side of the plate 23 away from the buffer groove 22 . A buffe...

Embodiment 2

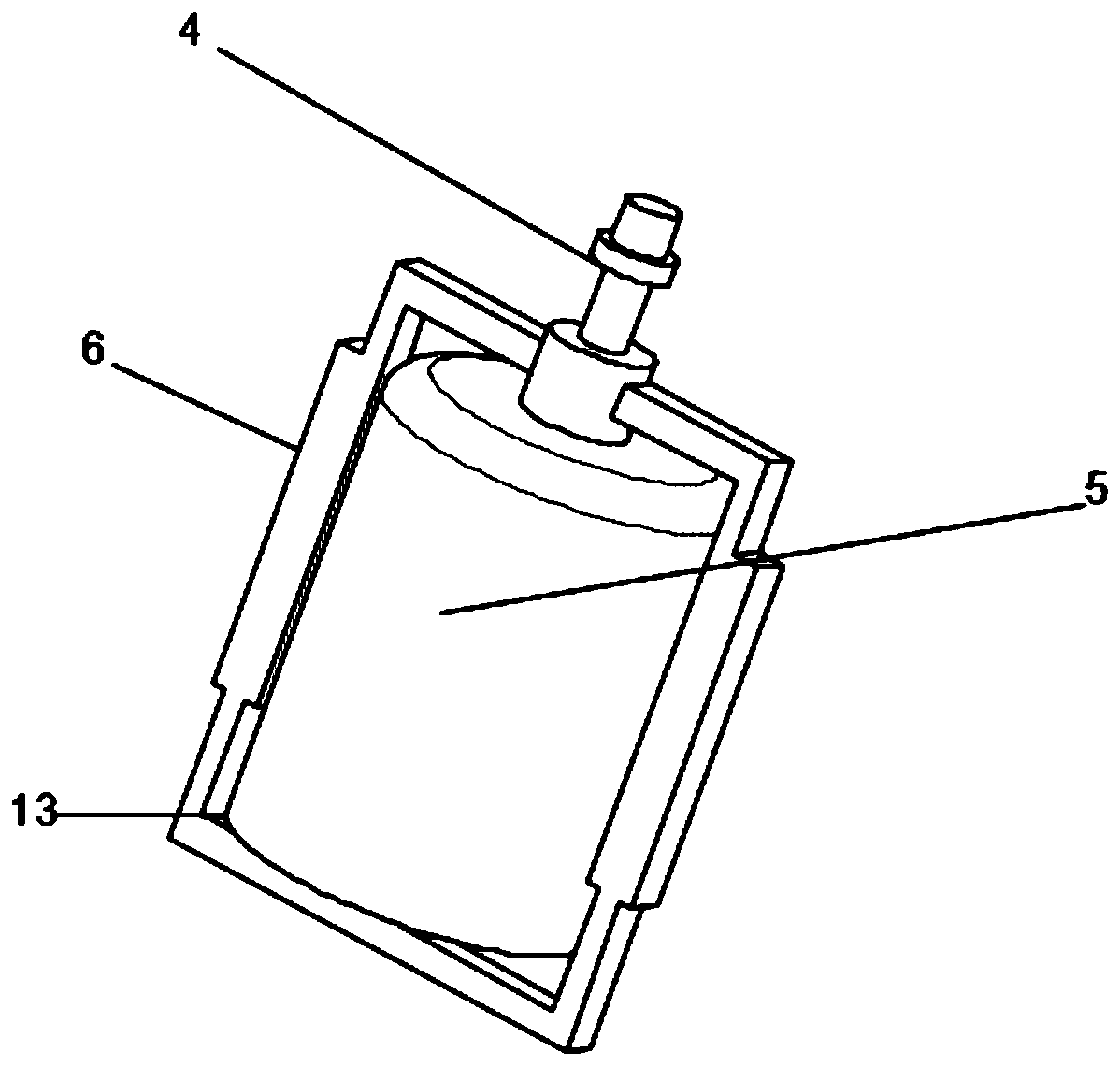

[0025] like figure 1 , figure 2 , in order to better protect the body of the micro motor 5, a protective structure 13 is installed outside the micro motor 5, and two sets of wires extending to the outside of the protective structure 13 are connected to the wire connection cover 11 on the top of the micro motor body 5 10. The wire connection cover 11 is convenient for the power supply connection of the micro motor body 5, the wire 10 is convenient for the connection between the micro motor body 5 and the power supply, and a fixing sleeve 6 is fixedly installed in the middle of the protective structure 13, which can improve the power supply to the micro motor 5. For protection, the fixing sleeve 6 extends upward to connect with the micro motor 5 , and the front cover 2 is installed on the upper part of the micro motor 5 .

[0026] Further, in order to improve the stability of the protection structure 13 for the protection of the micro motor 5 , in this embodiment, a layer of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com