Valve protective cover convenient to disassemble

A protective cover and valve technology, applied in valve details, valve devices, pipeline protection and other directions, can solve the problems of valves being easily damaged by freezing, high cost, and inconvenient to disassemble, so as to reduce the probability of freezing damage and increase the use of The effect of longevity and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

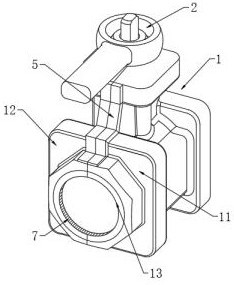

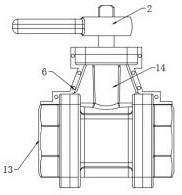

[0035] Example 1 see Figure 1-7 , the present invention provides the following technical solutions: a valve shield that is easy to disassemble, including: the valve body 2, the shell 1 and the clamping mechanism 9 are composed of three parts.

[0036] Wherein the valve body 2 is a metal casting;

[0037] The shell 1 is assembled from detachable parts, including a front cover 11 and a rear cover 12, the front cover 11 is formed on the left side of the valve body 2, the rear cover 12 is formed on the right side of the valve body 2, the front cover The bottom of shell 11 and rear cover 12 is provided with hinge 3, and hinge 3 is respectively fixedly connected between front cover 11 and rear cover 12 by bolt, and the bottom of front cover 11 and rear cover 12 is connected by hinge 3 rotation The front cover 11 and the rear cover 12 are symmetrical stainless steel covers, and the front cover 11 and the rear cover 12 can cover the valve body 2 for protecting the valve body 2 .

...

Embodiment 2

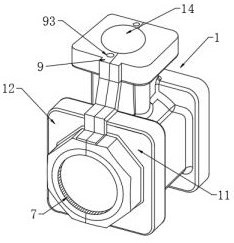

[0041] Embodiment 2 is on the basis of embodiment 1 such as figure 2 As mentioned above, the joint portion of the front cover 11 and the rear cover 12 encloses a horizontal through hole 13 extending in the horizontal direction and a vertical through hole 14 vertically communicating with the horizontal through hole 13 .

[0042] In this embodiment: in order to fit the valve body 2, the horizontal perforation 13 is used to accommodate the valve body, and the vertical perforation 14 is used for the valve stem to pass upwards.

Embodiment 3

[0043] Embodiment 3 is such as on the basis of embodiment 1 figure 2 As mentioned above, the inner wall of the horizontal perforation 13 along the two ends along the length direction and the inner wall of the vertical perforation 14 are provided with rubber rings 7 .

[0044]In this embodiment: in order to ensure the tightness between the valve body 2 and the casing 1, rubber rings 7 are arranged on the inner walls of the openings of the horizontal perforation 13 and the vertical perforation 14, and the rubber rings 7 are provided to seal the valve body 2. The gap between the valve body and the shell 1 prevents the corrosion of the internal valve body 2 due to excessive gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com